Automobile manufacturers are investing more into electronics than ever before. Functions that used to be mechanical or hydraulic are being electrified and often displayed digitally. This ranges from highly sophisticated, connected infotainment systems to Advanced Driver Assistance Systems (ADAS) to all the variations of drive trains that exist in electric (EV) and hybrid (HEV) vehicles.

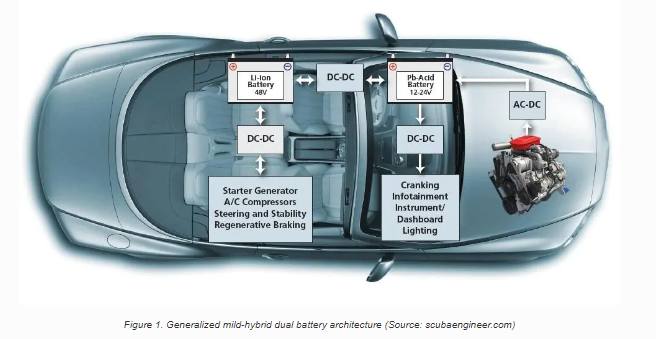

All of these systems require power, and the traditional single 12V battery supply has been replaced with interconnected 12V, 24V or 48V power nets that require regulators, converters and chargers to manage the power flows (Figure 1). And as always, size, weight and power need to be optimized.

DC-DC Battery Regulation And Charging

DC-DC Battery Regulation And Charging

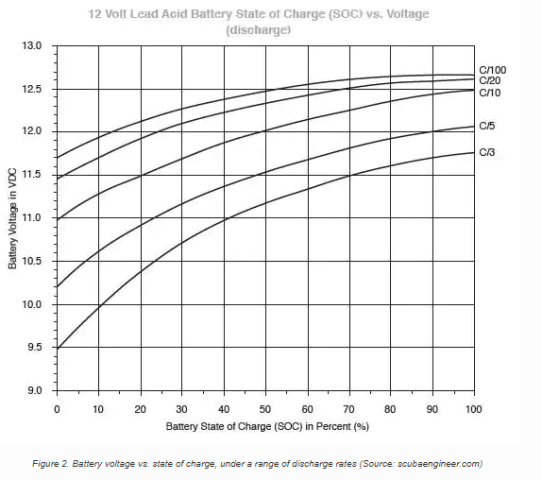

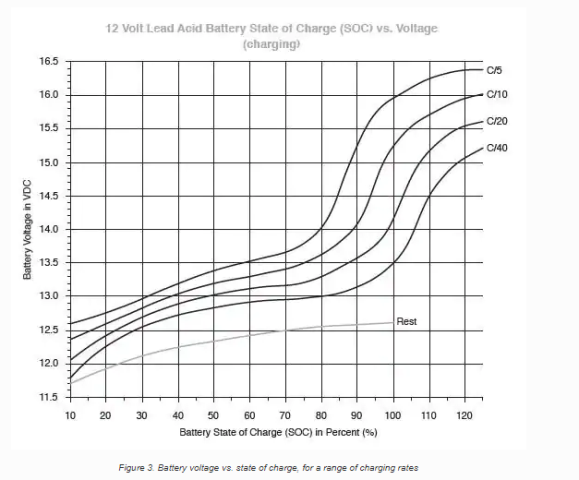

Battery-supplied voltages can vary widely with temperature, load, and State-Of-Charge (SOC). The wide voltage swings require a very flexible DC-DC regulator that can automatically and seamlessly transition between buck and boost modes.

For example, during regular use a typical 12V automotive battery output voltage might range from 8V-16.5V (Figures 2 & 3). Voltage swings are further exacerbated by cold temperature or when measured on aged batteries. The line regulator must also contend with batteries which are charged from alternators and must be able to withstand load dump scenarios that produce large inductive voltage transients.

If unchecked, these voltage spikes can be as high as 120V. Clamp circuits are required to keep these load dump voltages at or below 40V in 12V batteries, and 60V in 24V systems. These wide input swings exceed the capabilities of many regulators, which may stop regulating when their input exceeds 36V. Very few solutions have the ability to manage voltage swings over the entire input range of 8V-60V while maintaining a stable regulated output.

If unchecked, these voltage spikes can be as high as 120V. Clamp circuits are required to keep these load dump voltages at or below 40V in 12V batteries, and 60V in 24V systems. These wide input swings exceed the capabilities of many regulators, which may stop regulating when their input exceeds 36V. Very few solutions have the ability to manage voltage swings over the entire input range of 8V-60V while maintaining a stable regulated output.

Constant Current And Constant Voltage Regulation

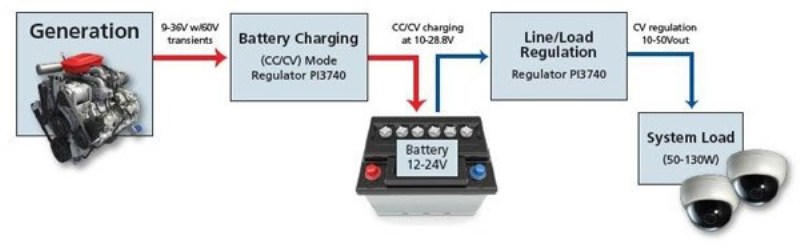

As a rule, load regulators are expected to provide stable load regulation with sufficient bandwidth to quickly respond to load transients. When employed in a battery-supplied system, there is the additional need to recharge the battery. A regulator with the ability to alternate between Constant Current/Constant Voltage (CC/CV) modes is required for a typical CC/CV charging scheme. Regulators with this capability eliminate the need for an additional dedicated regulator for battery charging.

Uniform Conversion Efficiency Impacts Thermal Design

Uniform Conversion Efficiency Impacts Thermal Design

Next generation buck-boost regulators surpass traditional regulators by improving efficiency over a wide input range. An important characteristic in assessing a buck-boost regulator’s performance is the flatness of the efficiency curve across the entire line input range. A flat efficiency curve means that the designer can assume a uniform heat load across the entire operating range.

Conversion efficiency directly affects thermal design and the reliability of the system, which impacts total system cost. The new generation of DC-DC regulators can enable a 2-3 point efficiency improvement compared to their predecessors. These incremental improvements in efficiency also expand the thermal margin in the system, allowing full power delivery over a wider ambient range.

Balancing Economy With Luxury

OEMs must balance improved fuel economy with demand for more in-cabin electronics. Available cabin space is relatively constant, so there are constraints to size and weight of power components.

The new-generation buck-boost regulators employing higher switching frequency allows for smaller energy storage and filtering components (inductors and capacitors). Those, together with heatsinks, are the largest contributors to the “S&W” of a power system’s Size, Weight and Power.

Next-Generation Buck-Boost Regulators

Dual battery vehicle systems are, therefore, fuelling the demand for new battery-supplied DC-DC conversion solutions, like the Cool-Power® ZVS Switching Regulator, PI3740. That need is compounded by the continued proliferation of aftermarket electronics accessories: not only audio/video/connected entertainment and infotainment, but also, navigation, video surveillance and recording systems, which are increasingly being added to public buses, delivery vehicles and taxis (Figure 4).

Today’s in-car accessories require a new generation of buck-boost regulators that are capable of wide input line regulation, and can provide both voltage and current priority regulation as part of a battery charging solution. With the ability to support both charging and regulation at high efficiency across the line input range, system designers can simplify their BOM and use a single DC-DC regulator to support multiple product designs. Flexibility, size, density and efficiency are some of the important characteristics that require careful consideration when choosing a power solution for today and tomorrow’s evolving automobile.