The objective of Virtual Laboratories is to bring a student closer to the lab.

A common theme of criticism of engineering education in India is the excessive emphasis on theory and lack of focus on hands-on experience. Although most will agree with this concern, it is not one of the best addressed of our times. The implications are grave enough to even question the employability of graduate engineers across disciplines. Inspired by the idea of adding a practical aspect to the engineering curriculums, the emphasis on Lab experiments and projects for real life problem solving started growing significantly. But, one of the major challenges in this process was that of the limited infrastructure available at engineering institutes. The world-class experimental setups, sophisticated learning resources and coaching expertise available to a strata of top universities largely remained limited only to their respective students. Is this really an unbeatable challenge?

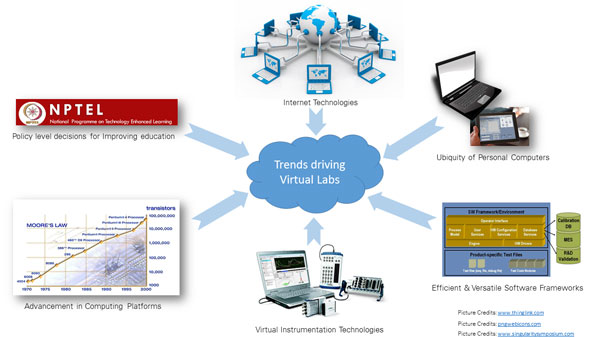

In the last two decades, we have seen tremendous advancement of computing technologies. Internet has become a part of our daily lives. Devices all over the globe are getting connected more than ever before. Cloud computing and advanced networking technologies are leveraged for new approached to system design such as Internet of Things (IoT). Easier software frameworks have made software development more accessible, efficient and versatile. Devices have grown more powerful and compact at the same time. A natural consequence of these advancements is the ubiquity of computing in engineering education. No wonder we see most engineering students own personal laptops as means to use educational tools! This wide reach Information and Communication Technologies (ICT) is what makes them a definite answer to the problem at hand. The success of Massive Open Online Courses (MOOC) initiatives such as NPTEL had served well to resolve the constraint on availability of high-quality classroom instruction in science and engineering. Taking a clue from its online courseware model, Ministry of Human Resource Development (MHRD), Government of India, under the National Mission on Education through Information and Communication Technology (NMEICT) launched the initiative of Virtual Labs (http://vlab.co.in/). The aim of this project was to provide remote access to laboratories in various disciplines of science and engineering to students through provision of virtual laboratories.

A Virtual Laboratory enables a remote user placed anywhere on the globe to perform an experiment on a physical experimental setup in an actual laboratory present in an institute. Users connected over the web can conduct these experiments operating on a graphical user interface on their own computers. Virtual Laboratories are typically accompanied by lab manuals, relevant theoretical concepts, web tutorials, and description of the physical setup in order to deliver a rich learning experience. These experiments are also usually classified and aligned to standard science and engineering course curriculums. The ability to work with sophisticated experimental setups virtually brings along many advantages such as:

- Better utilization of investment inhigh quality experimental setups and instruction resourcesdue to accessibility by users beyond the host institute

- Ability to conduct online experiments 24 hours a day, seven days a week, without limitation of space

- Accessibility for not just national but global engineering student community resulting into knowledge sharing across borders

- Increased enthusiasm of students due to option of conducting experiments of choice so as to focus on their areas of interest

All the advantages listed above serve as compelling arguments in favour of Virtual Laboratory initiatives. However, some limitations and challenges posed by the inherent ‘Virtual’ nature of the system should also be considered. Since a Virtual Laboratoryis essentially a remotely controlled environment, the real look-and-feel of the physical setup cannot be completely provided to the user. In order to get the experience closer to reality the console (computer station at the physical location) would have to be equipped with a mechanism to integrate an audio-visual feedback through cameras and sound system. To ascertain the physical safety of equipment, sensor feedback such as temperature, pressure or vibration needs to be provided to the user controlling experiment parameters. The GUI must also contain appropriate design that matches the tactile inputs required at the experiment panels. Needless to say that all these requirements are in addition to the actual experimental setup which involves interfacing the lab equipment with a computer through a data acquisition (DAQ) system including signal conditioning for sensors and drives for actuators, creating a software to control this DAQ system with an option of data logging, database access and limit controls for protection of the setup, creating a graphical user interface (GUI) for interactive control and monitoring and integrating this GUI over the internet to be downloaded as an application or accessed in a web browser, for remote control.

Typically the approach taken for such application development would be to choose an application development environment (ADE) which contains separate libraries for web integration, GUI development and instrument interface. The ADE would interface with hardware through driver APIs provided by separate instrument manufacturers. Firstly, this route requires significant investment of capital. Since the system is virtual, the investment in individual GUIs, processors, communication buses on benchtop instruments is unnecessary. All you require is a data acquisition system that can bring data on the console where further processes can be defined by the application software. Secondly, significant effort has to be incurred in building expertise in software and for integration of bits and pieces from different vendors. Creation of such a system using C, VC++, VB, .NET, Java or HTML could be tedious. Since the concept of Virtual Labs is not very deeply ingrained into our engineering education system yet, large part of the system may have to be developed from scratch. To overcome these limitations a platform based approach to virtual instrumentation is ideal.

A virtual instrument is a system which contains an industry-standard computer running a powerful application software combined with a cost-effective plug-in DAQ board though a driver software interface. At National Instruments a platform based approach of graphical system design is followed to create virtual instruments. NI LabVIEW is an ADE which lets you create such a virtual instrument for your custom measurement. Unlike most other textual programming environments, LabVIEW is a graphical programming environment. Your program is nothing but a flowchart of functions you think of while conceptualizing the algorithm. The way you think, the way you program… This essentially means that the effort and time of software development is greatly reduced. The UI is LabVIEW is inherent to LabVIEW programming thus eliminating the need of GUI-code integration altogether. NI DAQ devices interface seamlessly with LabVIEW creating unrivaled ease of Hardware Software integration. Functionalities such as data logging, database access and web integration are further simplified by configuration based APIs. When asked about integration of third party components in a virtual lab Prof. Vinod Kumar (Professor, Department of Electrical EngineeringIIT Roorkee) said, “Fields such as Biomedical Engineering require specialized equipment from even Third-party vendors. Some experiments also require simulation of parameters that are difficult to be measured physically. NI’s platform makes this integration very smooth”. To provide the real look-and-feel of the experimental, IIT Roorkee Virtual Labs use the Image acquisition and processing libraries in LabVIEW to show the live video feed of setup. Thus, you have hardware control and interface on one side and web integration on the other. LabVIEW serves as the platform for putting the whole system together.

The objective of Virtual Laboratories is to bring a student closer to the lab. An alternative approach could be to bring the lab to a student. When it comes to lab experiments in engineering, especially electrical, electronics, and communications engineering, students need electronic measurements, analysis and recording of results across courses. In the latter approach a student is equipped with a compact portable measurement and control device which can be simply plugged into a computer and used for data acquisition and control. The required functionality of the experiment, be it signal processing, signal analysis or real-time control can be implemented as a graphical code in LabVIEW. The initial investment in a DAQ device such as NI myDAQ, NI myRIO or Analog Discovery, would then keep yielding returns throughout the period of engineering education for the student by providing ability to make measurements on a computer instantaneously and complement the theoretical concepts learnt with immediate empirical observations. That would really complete the challenge that we started with!

Whether it is bringing labs to students or students to the lab, NI’s platform based approach can add immense value to the project of enhancing efficiency and effectiveness of engineering education. The philosophy of ‘Do Engineering!’ is central to all educational solutions by NI which makes it an ideal platform for futuristic initiatives such as Virtual Labs.

Author