Smart Highly Integrated IO-Link® temperature sensor reference design lowers cost and increases uptime than any discrete alternative

New Delhi, India—March 26, 2015—Maxim Integrated Products, Inc. released today MAXREFDES42# IO-Link temperature sensor reference design (RD). Industrial and Automation Designers can save power, cost, and space using this reference design.

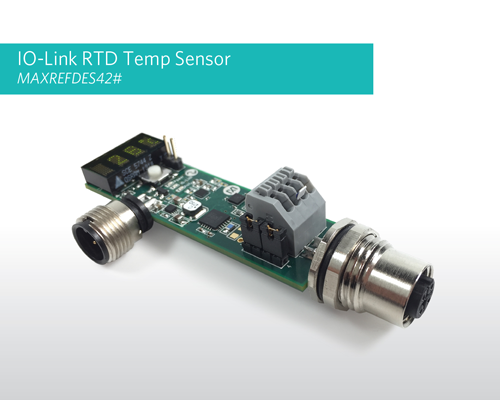

The new MAXREFDES42# IO-Link resistance temperature detector (RTD) joins the company’s portfolio of other IO-Link reference designs for industrial control and automation. This design’s highly integrated analog front end (AFE) measures temperature, while detecting overvoltage, shorts, and open circuits. This is a set of capabilities not found in competitive discrete solutions. The reference design consumes minimal power and provides better than +/-.5°C accuracy. The temperature appears immediately on an LED display for a quick and convenient snapshot of coarse temperature values. For user convenience, MAXREFDES42# fits in a standard industrial form factor. For versatility, it supports all three IO-Link speeds—no other competing device can do this. The MAXREFDES42# is available for use with a 2-wire, 3-wire, or 4-wire PT100 RTD over a wide temperature range. Applications include air, gas, and liquid temperature measurement.

The new MAXREFDES42# IO-Link resistance temperature detector (RTD) joins the company’s portfolio of other IO-Link reference designs for industrial control and automation. This design’s highly integrated analog front end (AFE) measures temperature, while detecting overvoltage, shorts, and open circuits. This is a set of capabilities not found in competitive discrete solutions. The reference design consumes minimal power and provides better than +/-.5°C accuracy. The temperature appears immediately on an LED display for a quick and convenient snapshot of coarse temperature values. For user convenience, MAXREFDES42# fits in a standard industrial form factor. For versatility, it supports all three IO-Link speeds—no other competing device can do this. The MAXREFDES42# is available for use with a 2-wire, 3-wire, or 4-wire PT100 RTD over a wide temperature range. Applications include air, gas, and liquid temperature measurement.

The configuration software for this smart IO-Link temperature detector was developed in collaboration with IQ2 Development. The MAXREFDES42# uses their IO-Link device stack to communicate with any IO-Link version 1.1-compliant master. This software control lowers operating cost because it enables fast setup, diagnosis, and event monitoring from a PC and without a trip to the installation site. Maintenance can be done at the PC and not on the floor.

We are adding this smart temperature sensor to our quiver of IO-Link reference designs to provide our customers with specific, highly integrated solutions,” said David Andeen, director of reference designs at Maxim Integrated. “Our highly integrated RTD-to-digital converter and IO-Link transceiver create a design rich in benefits with many, clear applications in the industrial space.”

“Maxim and IQ2 are two companies on the cutting edge of IO-Link,” said Frank Hörz, project manager at IQ2. This collaboration represents another successful design that can reduce our customers’ time to market and lower their operational costs too.”

Key Advantages

- Low Power: during operation over a temperature range of -40°C to 150°C, the system consumes less than 300mW of power by utilizing an industrial DC-DC step-down converter.

- Highly Integrated:integrated into the front-end is the MAX31865 RTD-to-digital converter which provides flexibility, robustness, and optimal performance for an IO-Link platform.

- Cost Savings: PC control with IQ2 software saves configuration and maintenance cost and increases uptime.

Availability and Pricing

- The MAXREFDES42# reference design is available for $99.

- For information on other reference designs, please visit Maxim’s Reference Design Center.

Additional Information

- More information about MAXREFDES42#: http://www.maximintegrated.com/en/design/reference-design-center/system-board/6048.html

- MAXREFDES42# hi-res image: http://www.maximintegrated.com/en/company/newsroom/graphics/img/MAXREFDES42_image_rgb.tif

- MAXREFDES42# schematic: http://www.maximintegrated.com/en/company/newsroom/graphics/img/MAXREFDES42_diagram_rgb.tif