Downhole cable wirelines outperform traditional wireline cables in cased hole applications

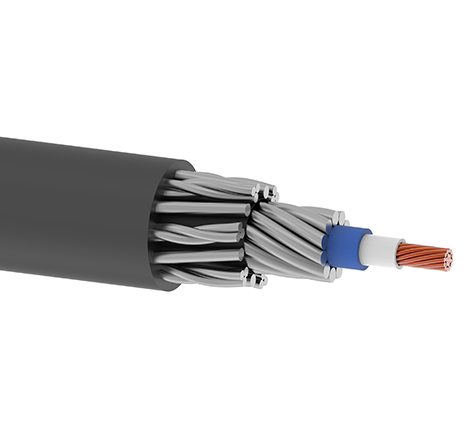

HARRISBURG, Pa.– July 27, 2021 – TE Connectivity (TE), a world leader in connectivity and sensors, has launched its Rochester greaseless cable technology providing a more efficient field operation for downhole logging applications. This eco-friendlier downhole jacketed wireline cable solution replaces steel cables in cased hole operations. Utilizing the Rochester branded DATEX 40 jacket material which is specially formulated, helps ensure the cable will not “birdcage” or high strand.

Additionally, TE’s Rochester greaseless wireline incorporates a specially designed steel armor package to deliver a breaking strength of 8,500lbs.

“We’re seeing an industry migration to this type of technology in the closed hole logging cable environment,” said Nigel Read, product manager for TE’s Aerospace, Defense and Marine business unit. “Our greaseless wireline cable is designed to offer faster run speeds coupled with cleaner operations and at a lower cost of operation to our customers, compared to conventional downhole wireline products.”

TE’s greaseless wirelines offers immediate benefits:

- Provides a lower coefficient of friction over traditional wireline cables using a specially formulated cable jacket material

- Improves rig up and rig down efficiency

- Demonstrates faster run speeds over traditional wireline

- Provides cleaner, more environmentally friendly option over traditional downhole wireline cables

For more information on TE’s Rochester cable greaseless wireline, visit https://www.te.com/usa-en/about-te/news-center/rochester-cable-greaseless-wireline.html