|

Counterfeit electronic components are electronic parts that are misrepresented as to their origins or quality. Counterfeiting of electronic

components can be an infringement of the legitimate producer’s trademark rights. Since counterfeit parts often have inferior specifications and quality, they may represent a hazard if incorporated into critical systems such as aircraft navigation, life support, military equipment, or space vehicles. The marketing of electronic components has been commoditized, making it easier for the counterfeiter to introduce substandard and counterfeit devices into the supply chain.

Why are counterfeit components such an issue?

The effect of counterfeiting of electronic components are very considered as electronic technology plays such an important part in so many areas of our daily lives from the obvious mobile phones and laptops to the less obvious such our cars, public transport systems and medical equipment. Counterfeiting represents a threat to this technology as, while we may be sure that the mobile phone or laptop we own is genuine, the components inside may not be. The consequences of counterfeiting of electronic components are particularly pervasive for a number of reasons:

- While environmental system testing should detect counterfeit components, functional testing may not. In-service failure is often costly to rectify in any application but the consequences of system down-time or even critical system failure where counterfeit components are used in safety critical applications, such as public transport, could be catastrophic

- Failure analysis in many applications often investigates the causes of failure at board (or lowest replaceable unit) level and may not detect a counterfeit component as the cause. Often, counterfeits are made of components that are difficult to source through official channels, which often forces component users to source parts through unofficial channels.

- Business relationships within the supply chain may be severely damaged and disputes may result in legal action.

- Component users may have unwittingly used non-RoHS compliant devices in a RoHS process, such as avionics.

Where counterfeit components coming from and what are is being done to stop it?

Increased levels of global trading and the increase in manufacturing operations in low cost regions such as Asia and Eastern Europe, has enabled the proliferation of counterfeit goods. In the electronics industry the supply network of OEMs has increased in complexity, in many cases spanning multiple partners spread around the globe. Controlling the activities of partners in this complex supply network, in a market where there is constant competitive pressure to reduce manufacturing costs, has become increasingly difficult.

What type of components is being counterfeited?

Not only the wide range of components that are known to be subject to counterfeiting, but also that the counterfeiting of relatively low unit cost components is considered to be profitable. Although, the majority of industry activity appears to be focused on the counterfeiting of semiconductors, other component types are also subject to counterfeiting. Some of the examples could be Amplifiers, Batteries, Capacitors (ceramic chip, electrolytic, tantalum), Circuit breakers, Comparators, Connectors, CPUs, Diodes, DRAMs and DRAM modules, Ferrites, Filters, Inductors, Lead-free solder, Linear ICs, Mil spec semiconductors, MOSFETS, NVSRAM modules, Opto couplers, Programmable logic devices, Power and power management devices, Potentiometers, Printed circuit boards, Resistors, Radio Frequency ICs, Thermistors, Transistors

How are components being counterfeited?

It is clear that a range of counterfeiting activities and the difficulties faced by component users in trying to detect components that may be counterfeit, bearing in mind the large number of different component types, different shipments and different suppliers that even relatively small companies have to deal with:

-

Components marked or stamped as Lead Free are actually PbSn (lead tin) or were PbSn but are stripped and re-plated with pure Sn (tin)

-

Components with gross manufacturing errors such as no die inside or wires

-

Components with a different manufacturer’s die to that indicated by external marking

-

Components with original component manufacturer (OCM) markings

- made by an authorized OCM offshore site no longer under their control

- made by an unauthorized manufacturer with original component manufacturer markings and / or recent date code, may use cheaper or incorrect materials including plastics or plating

- made by licensed offshore facility but marked as more expensive part

- may be parts not electrically tested and/or non functioning reclaimed failures

- may be unauthorized product overruns with no classification testing

-

Copyright infringementDocument falsification – the provision of forged Certificates of Conformance (C of C) and other documents purporting to provide evidence of traceability or even falsely claiming devices to have higher performance capability of specification

- stolen masks used to build product in unauthorized factories

- stolen designs of an entire product by de-processing parts

- optical copying and generation of masks without making improvements or innovations to the original design

-

Recycled components are counterfeit if sold as new but may in any case be ESD-damaged during clean-up

-

Re-marked componentsUnmarked surface-mount component visually unidentifiable

- incorrectly marked for example to pass off as a more expensive military or industrial spec part or part with higher electrical performance

- incorrectly marked to pass off non RoHS compliant parts as compliant or vice-versa

- date code updated

Strategies to avoid Counterfeit Electronic Components

By utilizing multiple different types of incoming inspection most counterfeit components can be discovered.

- DNA marking. Botanical DNA as developed by Applied DNA Sciences and required by the DoD’s Defense Logistics Agency for certain High Risk microcircuits to determine authenticity or provenance. Unique and un-copy able marks applied by manufacturer and/or distributor.

- Visual External Inspection for Signs of Resurfacing

- Visual Microscopic Inspection of Encapsulate Finish and Lead Surfaces

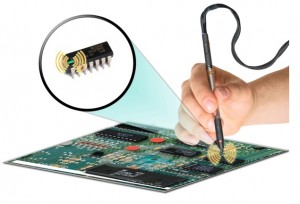

- X-Ray Inspection: By comparing the internal structure (of a homogeneous sample, same date & lot code) of electronic components certain types of counterfeit parts can be discovered. The “blatant fake” counterfeit devices exhibit vast differences in internal structure including, but not limited to different Die Frames and Different Wire Bonding.

- X-RF Inspection: In the wake of the RoHS initiative, X-ray fluorescence spectroscopy can be used to confirm RoHS status which is often overlooked by counterfeiters.

- Decapsulation: By removing the external packaging on a semiconductor and exposing the semiconductor wafer or die microscopic inspection of brand marks, trademarks, and laser die etching can be used to determine authenticity.

- Chemical : Technique utilizing heated acid to expose wafer or die packaged in plastics or resins

- Mechanical: Technique utilizing cutting, cracking, or chipping the ceramic or metal to expose wafer or die for inspection.

- SAM (Scanning Acoustic Microscopy) : A Scanning acoustic microscope can be used to discovered evidence of resurfacing and blacktopping by revealing laser etching below blacktop material

- Parametric Testing a.k.a. Curve Tracing: An inexpensive and expedient method to determine of a sample of product has identical electrical characteristics.

- Gross Leak and Fine Lead (Hermetically Sealed Components)

- Functional Electrical Testing

- QPL – Qualified Product List (Military Product)

- QML – Qualified Manufacturers List (Military Product)

- QSLD – Qualified Suppliers List of Distributors (Military Product)

- QTSL – Qualified Testing Suppliers List (Military Product)

Law For Detection & Avoidance of Counterfeit Electronic Components

Defense Federal Acquisition Regulation Supplement: (DFARS Case 2012-D055)

(a) Scope. This subsection implements the requirements of section 818(c)(2), National Defense Authorization Act for Fiscal Year 2012 (Pub. L. 112-81) and section 833, National Defense Authorization Act for Fiscal Year 2013 (Pub. L. 112-239).

(b) Contractors that are subject to the Cost Accounting Standards (CAS) under 41 U.S.C. Chapter 15, as implemented in regulations found at 48 CFR 9903.201-1 (see the FAR appendix), and that supply electronic parts or products that include electronic parts under CAS-covered contracts are responsible for detecting and avoiding the use or inclusion of counterfeit electronic parts or suspect counterfeit electronic parts in such products and for any rework or corrective action that may be required to remedy the use or inclusion of such parts.

(c) The costs of counterfeit electronic parts or suspect counterfeit electronic parts and the cost of rework or corrective action that may be required to remedy the use or inclusion of such parts are expressly unallowable, unless—

(1) The contractor has an operational system to detect and avoid counterfeit parts and suspect counterfeit electronic parts that has been reviewed and approved by DoD pursuant to 244.303;

(2) The counterfeit electronic parts or suspect counterfeit electronic parts are Government-furnished property as defined in FAR 45.101; and

(3) The covered contractor provides timely notice to the Government.

Tiny, Cheap, Foolproof: Seeking New Component To Counter Counterfeit Electronics – DARPA

The Defence Advanced Research Projects Agency

The DARPA Supply Chain Hardware Integrity for Electronics Defense (SHIELD) program seeks proposals to develop a small (100 micron x 100 micron) component, or dielet, that authenticates the provenance of electronics components. Proposed dielets should contain a full encryption engine, sensors to detect tampering and would readily affix to today’s electronic components such as microchips. Successful development of SHIELD technology would provide 100 percent assurance against common threat modes:

- Recycled components that are sold as new

- Unlicensed overproduction of authorized components

- Test rejects and sub-standard components sold as high-quality

- Parts marked with falsely elevated reliability or newer date of manufacture

- Clones and copies, which may be of low quality, or may include hidden functionality

- Components that are covertly repackaged for unauthorized applications

The dielet will be inserted into the electronic component’s package at the manufacturing site or affixed to existing trusted components, without any alteration of the host component’s design or reliability. There is no electrical connection between the dielet and the host component. Authenticity testing could be done anywhere with a handheld probe or with an automated one for larger volumes. Probes need to be close to the dielet for scanning. After a scan, an inexpensive appliance (perhaps a smartphone) uploads a serial number to a central, industry-owned server. The server sends an unencrypted challenge to the dielet, which sends back an encrypted answer and data from passive sensors—like light exposure—that could indicate tampering.

SHIELD is seeking proposals that revolutionize electronic authentication with potential scalability and advanced technology not available today. DARPA will host a Proposers’ Day Workshop in support of the SHIELD program on March 14, 2014

Counteract to make the inventory and supply chain free from counterfeits:

The uncertain and unstable market today with the technology advancements is the real challenge to be faced by the companies today. Combating against the fake parts is very much essential to protect the company’s supply chain, the products and the brand image.

1. Control the source and the inventory (the “supply chain”) – by properly maintaining, updating and reviewing the information as said in the introductory module.

2. Keep a better watch on life cycle of each component. Be ready with multiple alternate components and sources in case of the component nearing to its end-of-life (EOL). In case of single-source components, better have enough stock in-hand, even though it adds to the sleeping budget.

3. Prefer purchasing the components from the manufacturer directly as much as possible. If it is not viable, then approach the franchised distributors and qualified independent distributors. Proactively, get the contact details and addresses of the distributors from the original manufacturer directly or get them confirmed. Maintaining and assessing the potential suppliers can help a lot.

4. Adopt a thorough screening of components and perform inspections with sophisticated instruments like X-ray fluorescence (XRF), digital X-ray instruments, microscopes, etc., for destructive of non-destructive methods. After all, “it’s better and smarter to prevent than repair…!”

5. Check for the unnatural language, logos, fonts of the printed text, layout of the information, and compare the product information against the original purchase order.

6. Gather, update and store what codes (marking, lot, date, shipment, bar, serial, etc.,) are to be inspected and confirmed them from each supplier/distributor independently. Even though the extra time is consumed here, it saves a lot of time in the next stages and more importantly the customers and the brand image are not hit.7. Implement tracking system inside the supply chain such that every component is traced back to their purchase history, representatives involved and the date stamp.

8. Look for distributor’s/supplier’s certification, their revenue and history. Probably the preferred supplier’s list, if maintained, can provide more details and pointers to scrutinize the authenticity.

9. If feasible, subscribe to the industry’s available databases who maintain the overall reports and cases of counterfeits.

10. Implement stronger purchasing contracts that specifically deal with the clause for counterfeits and making the suppliers viable for product impoundment and financial losses.

11. Report the counterfeits to other buyers, stakeholders and criminal investigation authorities (GIDEP, ERAI). Do not return the counterfeit components to the seller.