Design engineers are now looking to silicon carbide (SiC).This wide bandgap (WBG) semiconductor technology offers better efficiency, higher switching frequency, and increased design density coupled combined with improved overall performance. The benefits can be derived by moving to SiC in steps or by switching completely using a bottom-up approach.

Mark Patrick, Mouser Electronics

The cost of energy has greatly increased over the last year, placing a squeeze on businesses and consumers alike. In Europe, the price of gas has grown by 47% between 2020 and 2021. Countries like Germany depend on gas for approximately 16% of their electricity requirements and, in the US, 40% of electricity is produced using natural gas. As a result, with space and industrial heating using almost 75% of the energy consumed in the EU and cooling requiring 10% of total US electrical energy demand, more efficient heat pumps and air conditioning solutions are becoming a more urgent requirement. In Southeast Asia where space cooling is forecasted to account for 30 per cent of peak electricity demand by 2040, more efficient products would also help to reduce energy demand.

Some countries are now outlawing equipment that burns fossil fuels so new buildings must use electrically powered heating and cooling systems (HVAC). Europe, North America, and China have defined energy efficiency standards for heat pumps and air conditioners which are designed to ensure this equipment is constructed using the best available technology. ESEER in the EU and SEER in North America, define the (European) Seasonal Energy Efficiency Ratio. This rating determines the ratio between cooling output and electrical energy input (BTU/Watt), adapted to seasonal outdoor temperatures. To help with understanding the rating, upgrading from a SEER 9 to SEER 13 system reduced power consumption by 30%. The SCOP rating (Seasonal Coefficient of Performance) applies to heating devices.

HVAC Simplified

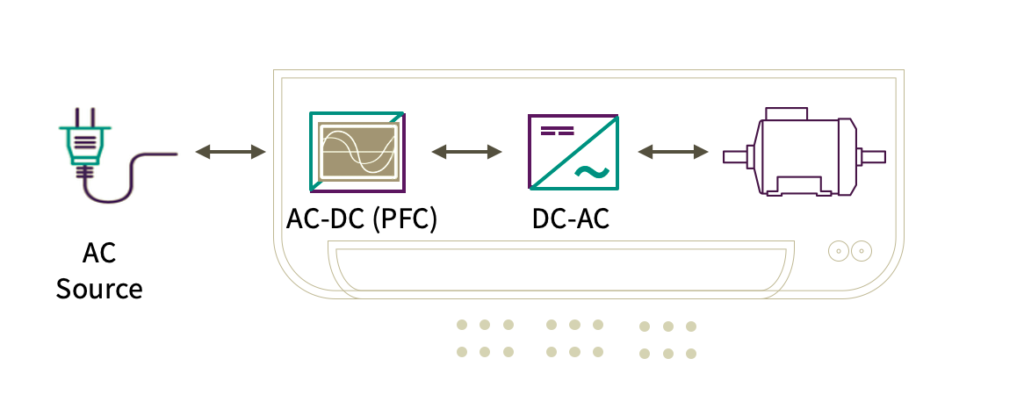

HVAC units, both air conditioning and heat pumps, include the same electrical functions. They are powered from an AC supply, perform AC-DC power factor correction (PFC) and have a DC-AC inverter to power a motor (Figure 1). For many years, silicon devices have been used in these systems, with IGBTs and MOSFETs employed in the power converter modules. However, with efficiencies now reaching 95% in many power designs, there are few obvious ways to attain even higher efficiencies using silicon.

As a result, Design engineers are now looking to silicon carbide (SiC).This wide bandgap (WBG) semiconductor technology offers better efficiency, higher switching frequency, and increased design density coupled combined with improved overall performance. The benefits can be derived by moving to SiC in steps or by switching completely using a bottom-up approach.

Using SiC to Improve Efficiency

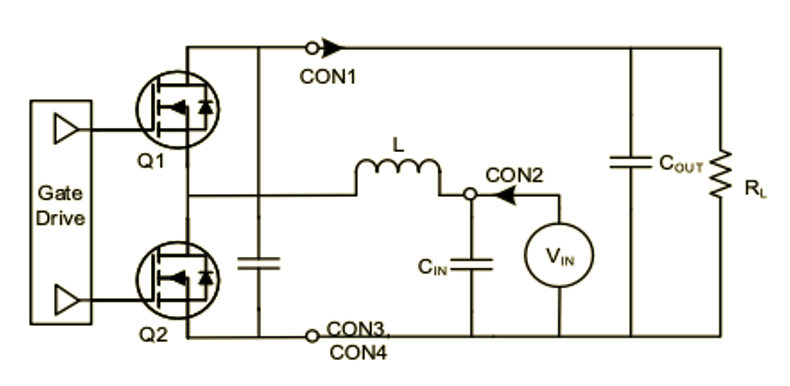

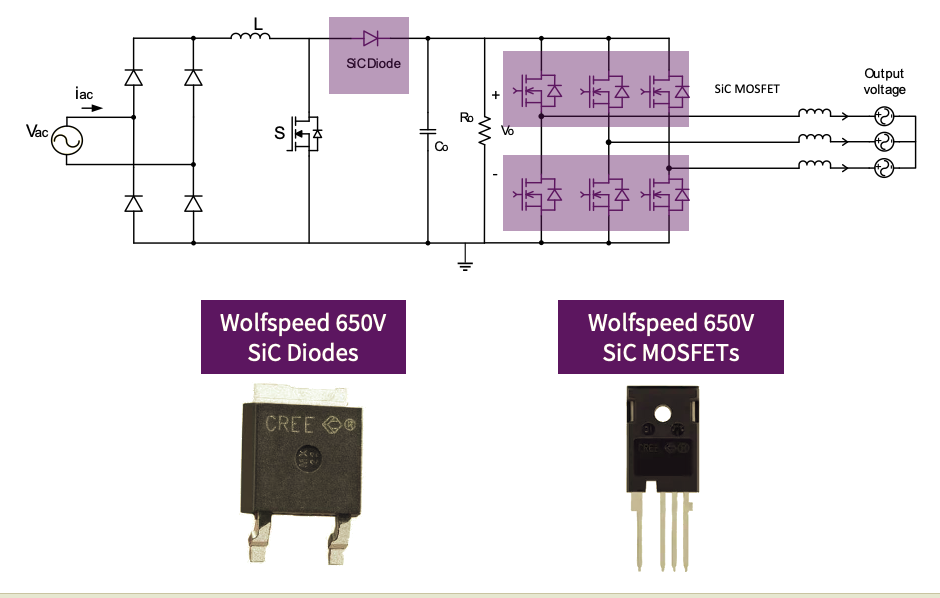

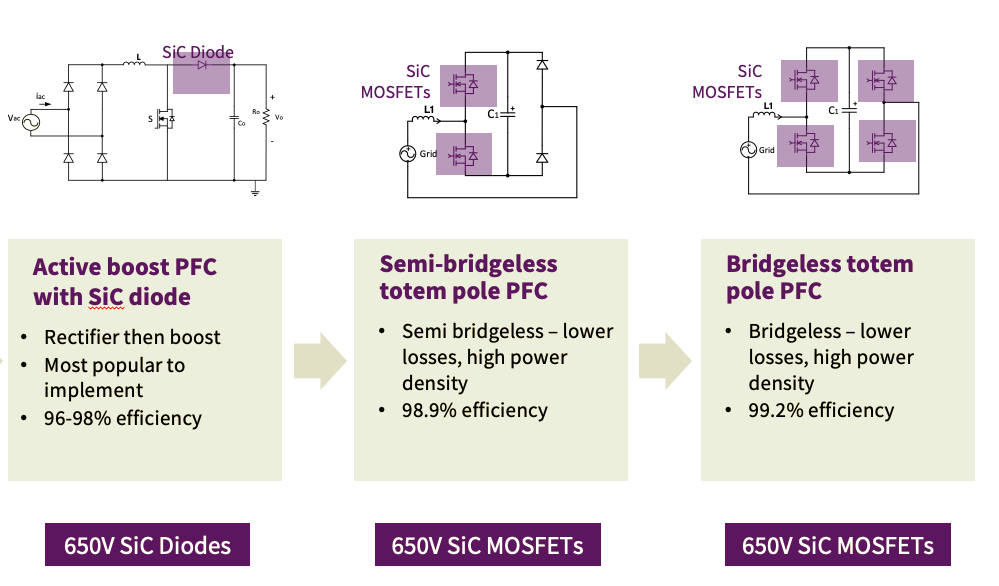

The PFC stage is the first obvious change that can be made. For boost converters in continuous conduction mode (CCM), an ultrafast boost diode is typically used to perform hard commutation. However, the reverse recovery properties of this device can cause of power loss, particularly as switching frequencies and power densities get even higher. Choosing a Wolfspeed650 V C6D series SiC Schottky diode greatly reduces such switching losses (Figure 2). In addition, other losses vary little with temperature or current. Therefore, a 4kW compressor driving a motor at 5kHz can achieved efficiency gains of 1.5%, which equates to a 60 W lowering in power consumption.

Next, the DC-AC inverter can be improved by replacing silicon IGBTs with suitable SiC MOSFET alternatives. Wolfspeed’s650 V C3M series SiC MOSFETs can provide efficiency improvements with less power loss (for both turn-on and turn-off), as well as a lower conduction loss due to their lower on-resistance. Making this change can deliver approximately a 2.2% improvement in efficiency, saving 86 W of power. When combined with switching to the SiC Schottky diode, the overall efficiency improvement reaches 3.6%, reducing total power consumption by 146 W, equating to a 50% SEER rating improvement.

Consider New Circuit Topologies

Simply replacing silicon with SiC switches in an existing circuit will not realize the full benefits of this new technology. The efficiency of IGBT-based designs begins to fall off when switching frequencies exceed 5 kHz. In the PFC stage, new topologies that leverage the improvements offered bySiCshould be considered.The semi-bridgeless totem pole (Figure 3) is one of the most cost-effective PFC topologies. This is implemented using only two SiC MOSFETs and a pair of PIN diodes andcombines good power density with efficiencies reaching 98.9%. A minor issue is a lower light load efficiency when compared to full-bridge topologies.

The bridgeless totem pole PFC requires four SiC MOSFETs and provides efficiencies of up to 99.2%, however, this benefit is offset by a more complex design and the higher overall cost for the bill-of-materials (BOM).

Starting Out with SiC

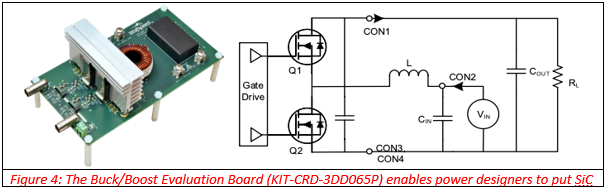

Many power designers prefer to move incrementally from silicon to SiC, to help them become more familiar with the technology better. SiC devices can switch at higher frequencies and have better recovery characteristics. They are also more stable over temperature, so it is recommended to first use these switches in a controlled reference application to discover exactly how they function. To help with this, Wolfspeed provide a Buck/Boost Evaluation Board (KIT-CRD-3DD065P) which includes two C3M (C3M0060065K) MOSFETs in TO-247-4 packages and also a 300 µH inductor (Figure 4). The board can be made to operate in either buck or boost mode with input /output voltages up to 450 VDC and power levels of up to 2.5 kW. It is ideal to use when measuring timing, overshoot, and switching losses at up to 100 kHz, or at even higher frequencies if an alternative inductor is selected. This kit is supported by design files, BOM and schematics, and a quick-start video that guides designers on how to use it

The semi-bridgeless totem pole AC-DC topology (CRD-02AD065N) can be evaluated in a similar way. It is designed for a 180 VAC to 264VAC input and delivers a 385 VDC output (at up to 2.2 kW). This high-efficiency, 80+ Titanium design features the same C3M0060065K discrete SiC MOSFETs with Kelvin connection to mitigate parasitic effects caused by the package. The converter provides a power factor of >.98 and a peak efficiency of 98.5% when operating at 65 kHz.

SiC – The Path of Least Resistance to Higher Efficiency HVAC

Wolfspeed invented the SiC MOSFET and has further developed the technology for over thirty years. During this time, SiC devices have been operating in the field for more than seven trillion hours. Wolfspeed is committed to WBG and continues to invest in fabrication facilities to increase capacity 30x by 2024.As energy costs rise and HVAC manufacturers look increasingly to SiC as part of their long-term planning to achieve higher efficiencies beyond silicon IGBTs and MOSFETs, designers and their purchasing teams can rest assured that Wolfspeed will be there to meet their needs.

This is important because of the market’s concerns about operating costs and the availability semiconductor devices. Commercial buyers and consumers are focusing on costs and are using efficiency labeling to help them search for alternative heating and cooling units. Moving to SiC can add half a SEER rating to a design and, by performing a complete redesign that derives the full benefits of SiC, even further improvements are possible. The wide choice of evaluation platforms available mean that power designers no longer have any reasons not to begin experimenting with SiC to give their designs a competitive advantage.

[1]https://www.cleanenergywire.org/factsheets/energy-crunch-what-causes-rise-energy-prices

[1]https://energy.ec.europa.eu/topics/energy-efficiency/heating-and-cooling_en

[1]https://www.eia.gov/tools/faqs/faq.php?id=1174&t=1

[1]https://www.e3g.org/news/why-should-the-asian-development-bank-care-about-sustainable-cooling/

[1]https://www.mouser.com/new/wolfspeed/wolfspeed-650V-sic-diodes/

[1]https://www.mouser.com/new/wolfspeed/wolfspeed-650v-sic-mosfets/

[1]https://www.mouser.com/ProductDetail/Wolfspeed/KIT-CRD-3DD065P?qs=GedFDFLaBXHKxgQlRF9Rug%3D%3D