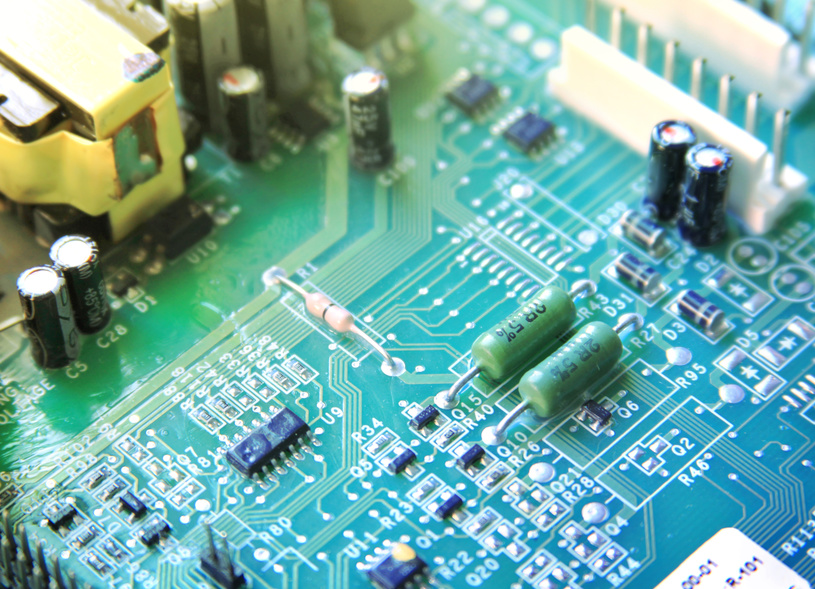

Recycling electronics might not be a new concept, but a new study by researchers from the Indian Institute of Science (IISc) in Bangalore and the Rice University in Houston has given the tech industry a new way to recycle printed circuit boards (PCBs).

Recycling electronics might not be a new concept, but a new study by researchers from the Indian Institute of Science (IISc) in Bangalore and the Rice University in Houston has given the tech industry a new way to recycle printed circuit boards (PCBs).

The study, published in the March issue of Materials Today, reveals that printed circuit boards are best recycled by pulverizing them into nano-sized particles. This method makes it much easier to recover and reuse valuable metals, polymers, and oxides found in the ubiquitous electronic components.

Researchers operated under the principle that freezing temperatures make for more brittle materials, which in turn create better conditions for sorting materials gleaned from the pulverized circuit boards. Researchers placed PCBs in a rotating cylinder where temperatures were lowered to -119 degrees Celsius. Once the materials were brittle enough, they were crushed inside the rotating cylinder with steel balls. Researchers then dispersed the resulting nanoparticles in water, where they could be more easily sorted.

Kamanio Chattopadhyay, a research guide, professor at IISc, and an author of the study, is optimistic about the results of this research.

“With some preliminary sorting, the method can handle most PCBs,” he told Eco-Business.

The technology, though still in the lab stage, could change the way PCBs are recycled. Automation has already changed the way they’re created. In fact, an automated PCB assembly line can place and solder more than 50,000 parts per hour, a far cry from the slow and meticulous process of hand-soldering.

Despite the more sustainable methods presented in the study, other researchers aren’t as optimistic about the scalability of this new method.

Physical crushing requires a lot of energy, especially when dealing with complex circuit boards with a variety of components,” said R. Parthasarathi, managing director of E-Parisara, one of India’s leading e-waste recycling companies. “Smelting circuit boards is more economical and feasible.”

Smelting may be more feasible, but it’s not currently regarded as an environmentally-friendly practice. But according to a Lucintel study, emerging trends in the PCB industry include miniature circuit boards and greener PCB development, so smelting may be on its way out. Even other electronic components like RJ45 Ethernet plugs, which are typically only good for 1000 to 2000 insertions, could be seeing more durable, sustainable recycling models in the near future.

Still, scaling this new PCB recycling method up to current industry waste levels could prove to be a long process. Researchers have begun working with industry leaders to demonstrate its effectiveness, but the end results remain to be seen.