ST creates technology for a sustainable world. Sustainability is a mandate that STMicroelectronics had been adhering to for over 30 years. In a recent media briefing, Jean-Louis CHAMPSEIX, Group VP, Head of Corporate Sustainability, STMicroelectronics speaks about ST’s commitment towards sustainability and enables customers to face environmental and social challenges as it continues to prioritize people.

He shared, “For ST, sustainability means three things: creating technology for a sustainable world, in a sustainable way; prioritizing people and protecting the planet; and creating a long-term value for all stakeholders including employees, customers, investors, and partners”.

Where ST stands today in leading sustainability?

Today we are happy to report that we plan to invest more than 3.4b$ in CAPEX for technology and capacity increase, in order to sustain our growth, especially in our responsible technologies enabling a more sustainable world. We exceed by far our target of more than 50% of our new product to be classified as responsible: last year 69% of our new product was classified as responsible, bringing a substantial greenhouse gas reduction throughout the life cycle from product to application, or substantial well-being benefits.

And we are also happy to report that following the new EU taxonomy regulation, 37% of our sales aim at very substantial greenhouse gas reduction throughout the life cycle.

These eleven years’ experience in product life cycle give us a great advantage, not only in improving ourselves because we manage everything that happens throughout the life cycle of our product, but also to give a very detailed reporting to all stakeholders. We provide for example our customers with all the CO2 emissions by product, from responsible sourcing and manufacturing to the end of life.

What are your upcoming strategies for the development of the industry?

In the coming year, we are committed to accelerate research and development investments. For example, 37% of our revenue aims at substantial greenhouse gas reduction, but 46% of our capital expenditure aims at substantial greenhouse gas emissions, so we want to increase our responsible sales. We want to accelerate focus on the three drivers of ST again: electric mobility, power and energy, and responsible applications in smart cities. It’s the strategy of ST for many years now, and it gives us a huge competitive advantage, because these markets are growing faster than the other markets and are also less exposed market is going down. We are also updating and improving further our unique product life approach to sustain our real competitive advantage and better support our customers.

According to you what are your top 3 Achievements?

First achievement we have done 12.8 billion US$ revenue last year, many years in advance versus our three-year plan. In 2022 we will generate more than 15 billion US$ of revenues, also several years in advance to our business plan. We will certainly exceed a lot the percentage of responsible revenues that we committed to reach 30% by 2025.We already reached 20% in 2021 and this number is continuously increasing, so we are in advance both in revenues and in responsible revenues.

We are also four years in advance in terms of safety, because we reached an employee recordable case of 0.12% by last year, and 0.15% including contractors, achieving our 2025 goals.

And we are also very much ahead in term of carbon neutrality on all indicators CO2 and renewable energy, but I’m happy to report as well that this year in 2022 we may be very close to our energy efficiency 2025 target.

Each time we reach a target, we are committing publicly to a new one. We are committed to never stop our sustainability journey. That’s why in our Sustainability Chapter we have 2025 and 2027 goals, and in coming years we will release 2030 goals, since each time we reach a goal we define a new 5-7 years one.

What you would like to add about your 2025 Goals?

Actually, we are ready for our 2027 ambitions as well, to be a 20 billion company with 50% gross margin and 30% revenues coming from responsible products. By 2025, we will for sure be compliant with the 1.5° C scenario of COP21, and we will be 80% of renewable electricity and very much in line with the next step of 100% renewable electricity by 2027. We are also confident to meet all other targets, like people engagement, not only best in class, but 10 points above local norms in the major countries in which we operate, with at least 20% women in management levels. Again, we’ve proven to market that ST is committed to its engagements.

What does sustainability at semiconductor plants include in terms of technology and how is the semiconductor industry doing, compared to other industries?

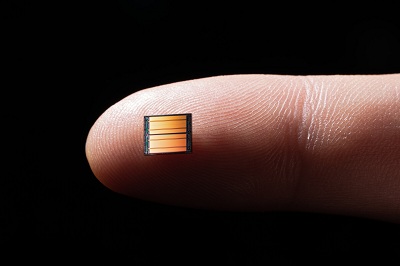

Sustainability in semiconductor is absolutely critical because semiconductor is an industry that uses a lot of resources. At ST, we say that we are producer of chips, but in reality, we produce even more litters of ultrapure water than the number of chips. So, every year we manufacture, by ourselves, thirty billion liters of ultrapure water typically. That’s why 30 years ago, ST started all of these programs in order to be very responsible. Even if the price of water is not a problem, we feel responsible. The way we work on carbon neutrality is ensuring that all ST’s plants follow the same pattern of implementation, as I just presented to you. All the Asian sites, and all the world sites have a sustainability committee, they all have a similar, detailed sustainability roadmap for the next three years. They all have specific targets, of course, depending on the local materiality. If you are backend site, front plant, sales and marketing site, of course it’s different materiality, but they all follow all the topics. And this is very important because in ST, when I say, we do sustainability in the sustainable way, we really engage the business so that sustainability is embedded into the business.

Not only semiconductor can have a significant footprint, but semiconductor is a fantastic enabler for low carbon society. You cannot make electric car without semiconductor; you cannot transition to low carbon application. You rely on semiconductor solutions to reduce the power consumption of electric motors, for example, and for the smart industry to reduce its overall consumption. You cannot have aneco-building if you don’t have sensors to really adjust the temperature, or to implement some smart system managing the heating of your building. Semiconductor has a huge responsibility in terms of footprint and is a fantastic enabler in terms of handprint. And ST decided to be world model in resource and emissions footprint and to be a leading actor in handprint.

Is there any part of ST’s sustainability plan that is particularly difficult to implement? How does ST overcome it?

We have positive problems and positive challenges. Because we started30 years ago, everything which was easy has been done and everything which was a little bit difficult has been done. The remaining things are very difficult to do, but we are still progressing. It’s true for almost all the topics. One of the problems facing ST is that it’s difficult for us as a leader to find external partners because actually our experts know more than an external partner. So sometimes when we take external partners, they failed to find new ideas to improve because what we do is already so advanced.

And the way we overcome these challenges is to be constantly innovating and trying pilot initiatives everywhere. After we learn how to do, we will duplicate them. That’s the way we do it. We sign partnership with some people to innovate together in this field. And we also contribute by helping the semiconductor world as we are leading. For example, we lead the EHS committee of the World Semiconductor Association. And I am leading myself the task force of the World Semiconductor Association on extra financial reporting. We try to develop the whole industry in order to face the challenges all together, but basically there is nothing blocking us. It creates engagement. We are an engineering company. If you want to engage engineers, you have to bring challenges. We have plenty of challenges and create a very engaging, virtuous loop for them to find new ideas and to invent the world of tomorrow.

How is ST keeping a check on its carbon neutrality by 2027 goal?

At ST we automatically monitor all performance of the sustainability every month. We have quarterly review with the CEO and all the presidents on all the performance. Internally, we publish the performance of the company and all the indicators. And here, I just show you an extract of this. Every quarter, we report also to the supervisor board with all indicators, and qualitative assessment of the risks. And of course, we have a monthly program review because we this is the way to embark all of the employees and leaders of the company through hundreds of programs. We have many global transformation programs on the topics I have mentioned for 2022 and 2023.For example, at the end of November this year, we have a workshop with the top 250 leaders of the company, on what it means to be sustainable leaders in the next 3 years. Following this workshop, we will adjust the leadership development for these people.

Against the backdrop of downward global economy, rising inflation, and weakness in demand, will it affect the implementation of the corporate sustainability strategies and how to better overcome external pressure?

The situation of the world today, the inflation, price increase of electricity, the risk happening in the supply chain, are accelerating the sustainability. They don’t bring complex challenges for us. They make the sustainability even more important and providing us with more payback than initially designed. When we implemented years ago, very aggressive energy saving investments with four years payback period, it was quite courageous. Some companies may have preferred to make this investment in order to grow the production or to develop a new product. But ST was allocating a part of the investment to make energy saving. And today with the price increase of electricity, the four years payback period became less than two years. Actually, the current situation is making us with even bigger competitive advantages somehow.

Current challenges also create the conditions to engage people in many initiatives. We share part of the value generated by the company to employees through the sustainability index of the short-term incentive. Last year we paid that index on stretch (above the goal). We also implemented a salary increase in September last year, on top of the yearly one. It helps us to retain talents better than some other companies.

All of these aspects of current situation today, and the external pressure are indeed accelerating further the sustainability at ST. It creates many challenges, of course, for everyone, for the company, for our customers and for our suppliers. But in terms of sustainability, it just demonstrates how sustainability is important in today’s world. So, it brings no impossible challenge but again even further acceleration of the sustainability.

The sustainability is also embedded into ST’s business through our market drivers: smart mobility, power and energy, and smart city applications. This is not only protecting our consumers but also provide huge business opportunities.

How has ST achieved energy saving and reduction in carbon emission in your fabrication process?

Today ST is disclosing transparently the energy consumption of the company. So, if you go to the sustainability report of the company, you will find the consumption of electricity for previous years. Last year, ST’s total power consumption was 2.5 terawatts almost exactly. The larger part of this consumption is coming from the manufacturing operations. That’s 95% of the total consumption of ST. Then we have plenty of small R&D offices, small scale offices, but they are not material compared to frontend facilities, which, let’s say, represents more than two-thirds of our total consumption. And the rest mainly comes from the backend sites because we do very advanced packaging in some backend sites to engage customers in new silicon carbide solutions in electric cars for example. The packaging becomes quite important. The consumption in the backend sites is also increasing a bit, but the main consumption is coming mostly from frontend sites. It is not new that technology is constantly changing together with new consumption. The good news is that ST has grown in plants where we were already based. We have not built frontends into new places. We are adding equipment to existing ones, in the middle of existing Fab. Let’s take the example of Singapore. We did first a five inches wafer Fab, then six inches, six inches extension, six inches extension of the extension, and eight inches, all of them at the same place. So, we took advantage of all the knowledge and all the infrastructure to execute energy-saving. That’s really a strength. Each time we grew up, especially in the frontend sites, we took advantage of knowledge, expertise and solution to decrease energy consumption.