By Alexandra Foley, Technical Writer, COMSOL

The most effective simulation is one that is able to capture and combine all physics in a single simulation environment, where they are coupled the same way they are in nature. The objective is to find a self-consistent solution that satisfies all physics. This is the multiphysics approach that makes COMSOL MultiphysicsÒ so unique, and it has revolutionized the design process.

When setting out to create a new invention, an engineer follows a workflow that includes producing a CAD model,building a prototype, and finally verifying and optimizing the product for real world use. However, with new technologies, this workflow process is changing to include conceptualization using simulation software early on in the design process. With simulation, an engineer can take a great idea and transform it into a great invention, right on the computer screen.

Computer aided engineering (CAE) tools are what make this analysis and optimization possible. Such tools allow engineers to simulate their products and test how they will perform under real operating conditions, even before they enter the testing phase. And withsimulation, engineers are finding that testing and experimental phases can be completed in just a few weeks, instead of the months it used to take to optimize a design. How is it that CAE toolsare able to do this?

It all comes down to the ability to provide an engineer with accurate information about their simulations throughout the design process. It’s not hard to agree that the most powerful simulation software would be one that provided the most accurate results about a product’s performance. What’s more difficult to define however, is how simulation should go about producing these results.

At COMSOL, we believe that the most effective simulation is one that is able to capture and combine all physics in a single simulation environment, where they are coupled the same way they are in nature. The objective is to find a self-consistent solution that satisfies all physics. This is the multiphysics approach that makes COMSOL MultiphysicsÒ so unique, and it has revolutionized the design process.

It’s a Multiphysics World

Why should a simulation software take into account only one physical effect? In the real world, coupled physics are the norm. Any simplifications applied during the design phase—such as considering the physics involved as independent from each other—risks jeopardizing the project down the road with expensive changes and even product recalls. This is where multiphysics simulation makes a big difference. It supports the designer by building realistic simulations that include and couple all relevant physics effects influencing the product, therefore providing an accurate picture of how the design will satisfy real world requirements. These simulation results can be used to gain an understanding of the product’s behavior, and drive key design decisions.

For example, consider how an automotive companymodels the plastic bumper of a car. Mechanical stresses, such as what could be modeled in the Structural Mechanics Module of COMSOL Multiphysics, would be important given the nature of the object. However, understanding how this design will be have when other physicscome into play is vitally important as well. How would the bumperperform whenexposed to below freezing temperatures, when the plastic became brittle? In this case, heat transfer and chemical reactions need to be simulated. What about considering aerodynamics? Optimizing for these physics effects can result in a design that is both safe and fuel efficient.

All these effects, and many others, can be simulated, optimized and refined using COMSOL Multiphysics. This is what makes COMSOL Multiphysics so powerful: it provides userswith the ability to simultaneously includeand analyze any physics effects in one easy-to-use interface.

COMSOL Multiphysics Software Architecture

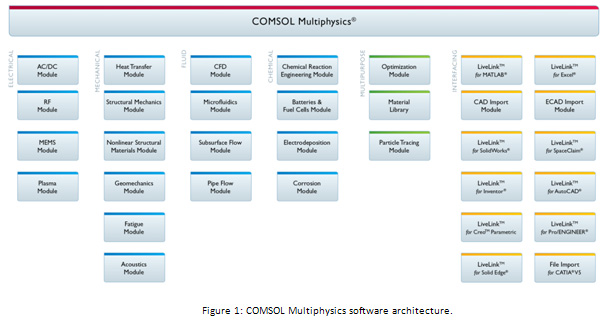

The architecture ofCOMSOL Multiphysics allows users to work in an integrated environment where any physics can be coupled in the same graphical user interface (GUI). This GUI is used throughout the simulation process—from defining the geometry,setting up the physics, creating the mesh, and finally to solvingand optimizing the results. In addition to the main product, COMSOL Multiphysics, there are several modules which address specific applications (see Figure 1). And of course, everyfeature added by the modules can be coupled with each other and combined with the base package.

Faster Simulations: The Key is in the GUI

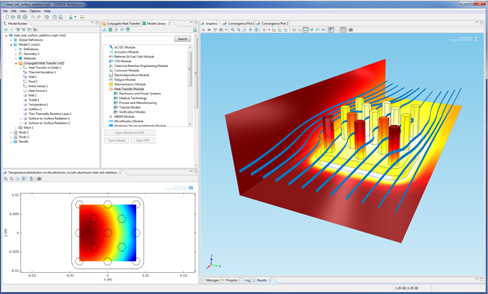

The COMSOL Desktop is the GUI of COMSOL Multiphysics, and it has been created to facilitate collaboration across design teams. This interface is specifically designed to be straightforward and intuitive, allowing for more time to be spent on simulation and less time spent on learning the software. The userinterface is uniform throughout, no matter which physics or application is being simulated. Therefore, once you understand the basic package, you have the ability to use any application.

Figure 2: Overview of the COMSOL Desktop. Simulation of a common heat sink is shown, where fluid dynamics and heat transfer are coupled.

Simply by selecting the physics that are relevant to a specific application from a menu, the user can set up a simulation in minutes. For all common multiphysics problems the coupling between the physics involved is fully automated. Joule heating, thermal stress, electrochemical reactions, fluid-structure interaction (FSI) are just but a few examples of the many predefined couplings that are available in COMSOL Multiphysics. Any non-standard physics can be freely defined in the user interface, allowing users to customize the program to meet their own needs. With any specifications that a user stipulates, COMSOL Multiphysics automatically represents predefined physics as well as user-defined physics, and computes a numerical solution to that system.

The result of such a multiphysics approach? A simulation software whose reports are accurate to such a high degree that in many areas, physical testing can be significantly reduced, or even bypassed altogether. Reports from the over 850 user presentations at COMSOL Conferences worldwide indicate that COMSOL Multiphysics delivers accurate results, fast. You can check out the User Presentations on the COMSOL website at http://www.comsol.com/papers.

Mechanical Engineering Simulations

Of the many engineering disciples, mechanical engineering is the most comprehensive, encompassing a wide variety of engineering fields and specialties including structural mechanics, acoustics and heat transfer. COMSOL Multiphysics reflects this diversity by offering a wide array of application-specific modulesrelated to the mechanical field (see Figure 1).

Heat Transfer Module Helps Toyota to Cool Down Under the Hood

The Heat Transfer Module is an important tool for many COMSOL Multiphysics users. Since almost every engineer must consider thermal effects in the manufacturing and product design process, the Heat Transfer Module is a versatile tool that can handle many different forms of heat transfer. Among these is the ability to model heat transfer via conduction, convection and radiation, as well as the capacity to couple these to other physics like structural mechanics and fluid flow.

When developing the sophisticated cooling systems in the Prius, the Toyota Research Institute of North America (TRI-NA) turned to the Heat Transfer Module for answers to their design constraints.

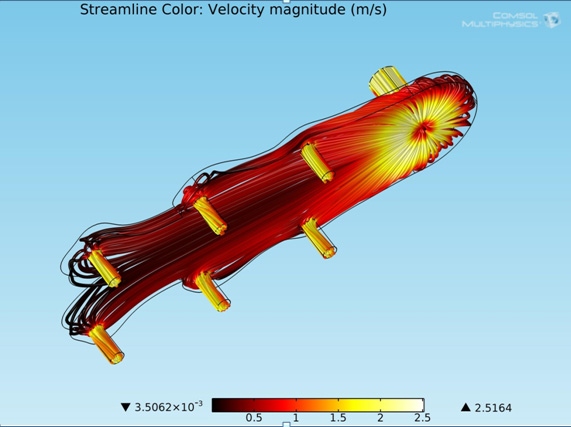

Figure 3: Fluid flow across a cold plate in the Toyota Prius where topology optimization was used to balance the flow rate, and minimize pressure drops.

Researchers at TRI-NA faced a daunting task: how could they create a heat sink that was smaller than previous models, while still dissipating the same amount of heat? Modernized electrical power systems in the Prius requiredthat the cooling plate used to keep electronics from overheating needed to be half their current size, while still using the same amount of power to pump coolant across the cold plate. Using COMSOL Multiphysics, TRI-NA developed a combination jet impingement and channel-flow-based cold plate that allowed for cooling to take place without a significant drop in pressure. By optimizing the design, Toyota researchers were able to develop a heat sink that was not only smaller in size, but that also dissipated heat at a 12.8 percent more effective rate than previous models. Figure 3 shows the coolant flow, which was simulated using fluid-flow topology optimization studiesto balance the flow rate to each outlet nozzle. Read the full story in the IEEE Supplement sponsored by COMSOL at http://www.comsol.com/offers/mphsim.

Electrical Applications

Almost every technology in the modern world relies on electrical engineering in one way or another. We interact with electrical applications in our daily lives without even realizing to what extend we depend on them. Whether it be opening the refrigerator to get a cool drink on a hot summer day, flicking on the lights when it gets dark outside, or using a cell phone to call a friend, we are relying on electrical engineers to make our lives easier.

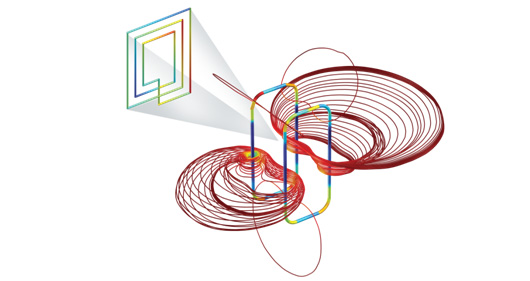

Figure 4: In an RFID, the reader antenna generates an electromagnetic field that energizes a chip inside the tag. Shown is the electromagnetic field in both parts.

Modules devoted to electrical simulation aimat making simulation easier for such applications. COMSOL Multiphysicsoffers an extensive model library of simulation examples. In the case of electrical designs,the available simulations deal with electromagnetic inductors, thermal drift in a microwave, inductive heating systems, and among others.

The model in Figure 4 is one such example of a simulation available in the COMSOL Model Library. It was created using the AC/DC and RF Modules, and shows a Radio-Frequency Identification (RFID) system consisting of a transponder with a tag antenna (left) and reader antenna (right). The reader antenna generates an electromagnetic field that energizes a chip inside the tag. The electromagnetic field is modulated by the tag’s circuit and is recovered by the reader antenna.

These antennas are common in many mainstream products. One application is in a car key, where a key is linked to a receiver in specific car, making thekey harder to forge. Additional applications include cell phone antennas and clothing tags for inventory control.

Besides the simulation areas mentioned, users are also working on applications involving fluid flow, chemical reactions and optimization in all disciplines. COMSOL Multiphysics has dedicated modules that specialize in a variety of applications and areas, and the product suite continues to be expanded and improved.

Optimized Designs Are the Future

It is evident from the examples discussed so far that the need for accurate simulations will increase in the coming years, as engineers and researchers continue to turn to CAE tools to deliver better, safer products. The software needed to achieve such results will have to encompass all the physics relevant to the application being simulated, and couple them in the very same way they interact in nature. Moreover, such a tool should allow users to easily investigate several operating conditions and explore the advantages of different designs. COMSOL Multiphysics is already the future of simulation, since it makes these capabilities available to all existing and new CAE tool users.

ExperienceCOMSOLMultiphysics at the next free hands-on workshop near you. To register, visit http://www.comsol.com/workshops.

tags

Simulation Software, circuit simulator, Simulator Software, Simulations