By Vikas Choudhary, Analog Devices, Inc.

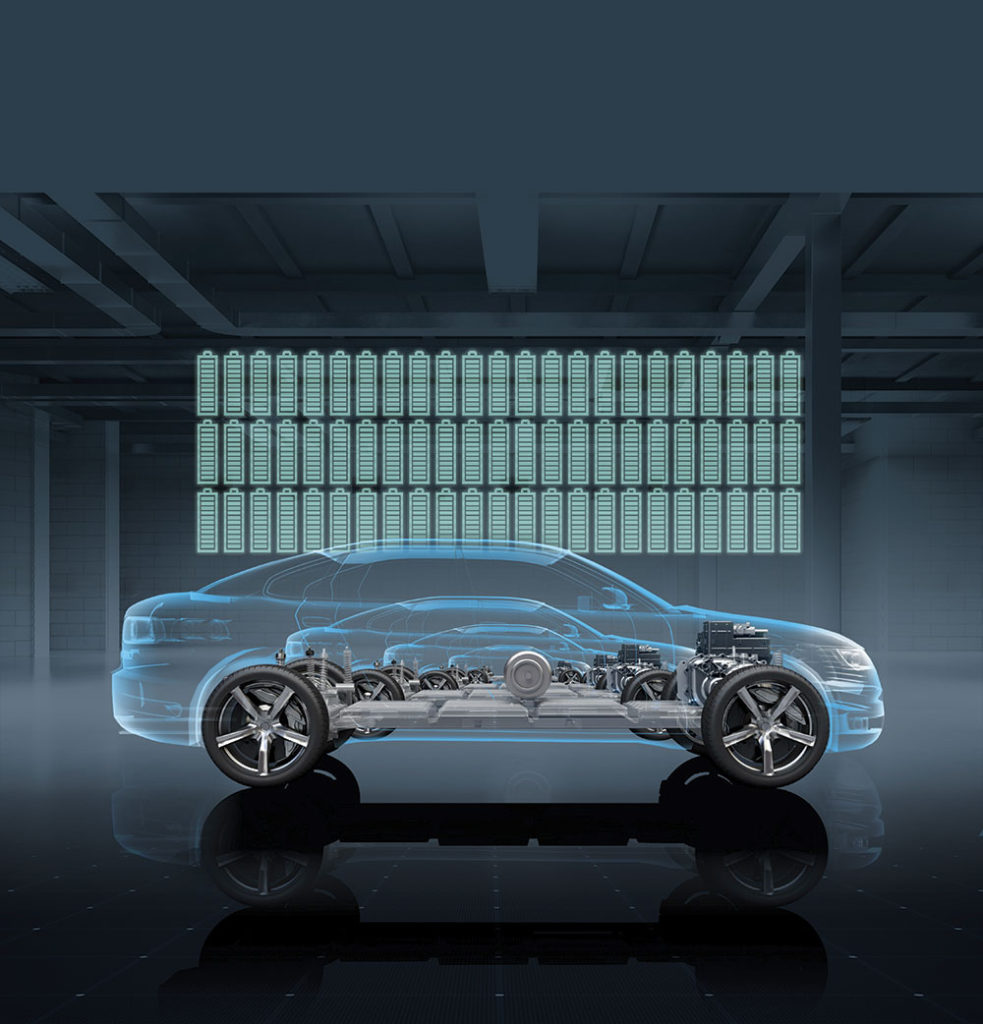

Driven by tighter CO2 regulations and more eco-conscious consumers, the pace of migration to electric vehicles continues to accelerate, with up to 10% of all vehicles sold by 2025 expected to be battery-powered, compared to less than 1% today. This is despite the high cost of the batteries, which stubbornly remain approximately half of the overall cost of the vehicle.

Driven by tighter CO2 regulations and more eco-conscious consumers, the pace of migration to electric vehicles continues to accelerate, with up to 10% of all vehicles sold by 2025 expected to be battery-powered, compared to less than 1% today. This is despite the high cost of the batteries, which stubbornly remain approximately half of the overall cost of the vehicle.

While there are many factors that determine the cost of the battery, one area in which manufacturers can make significant headway in reducing cost is during the final stages of manufacturing. Specifically, during battery formation and test, which can account for up to 20% of the cost of an EV’s battery.

Battery formation and test is a time consuming process involving multiple charges and discharges that activate a battery’s chemistry and can take up to two full days. This necessary procedure readies the battery for use and is critical to ensure its reliability and quality. Due to how slow the process is, it is a significant bottleneck that prevents battery manufacturing from achieving greater throughput that will lower the overall cost to produce batteries. Partnerships between EV battery manufacturers and suppliers with formation and test systems expertise are allowing them to increase their attention to reducing the time and cost involved at this crucial stage of manufacturing while still maintaining the precision required for advanced battery chemistries.

Faster Throughput Equals Lower Battery Cost

To decrease the cost of batteries, manufacturers need to take a holistic approach that starts by leveraging suppliers’ system-level expertise to reduce the overall battery test circuit footprint while increasing the number of channels. It’s important to note that both must be done while maintaining the accuracy, precision, reliability, and speed of their battery formation and test measurements to ensure safety, performance, and reliability requirements are met.

This is not easy to do. For the front end, the power supplies driving the battery charging circuits need to be tightly controlled. Going deeper, battery formation and test requires close monitoring of current and voltage profiles used during battery cycling to prevent overcharging and undercharging. This ensures safety during test, while also maximizing battery longevity, which greatly lowers overall cost of ownership for the end user.

For these critical battery measurements, very high quality instrumentation amplifiers (in-amps) and associated shunt resistors are needed to measure battery charge/discharge current to better than ±0.05% accuracy, even under harsh factory conditions. The same level of accuracy applies to the difference amplifiers used to monitor the voltage over the entire thermal operational range.

There are a number of ways to incorporate these components into a full solution, but it is a significant challenge to maximize performance and minimize the system footprint. This is the reasoning behind ADI’s integration of the analog front end, power control, and monitoring circuits in a single IC, the AD8452. These ICs can include battery reversal prevention, overvoltage protection switches, and smart controls to prevent overcharge of batteries, and they can reduce the system footprint by 50%. This suite

of capabilities allows battery manufacturers to incorporate more capabilities into test systems that will simultaneously make more efficient use of factory floor space. Moreover, they allow manufacturers to design systems with more functionality and more robust testing procedures.

Efficient power conversion is, in turn, another opportunity to drive further system performance. By using the advanced switching architectures, test systems can minimize power consumption by enabling bidirectional energy exchange with the grid. Efficient power conversion also reduces the need for heat management equipment, which can add to the system’s overall cost and power consumption. The net result is a reduction in wasted energy and manufacturing cost. Enabling these capabilities requires an appreciation of system features, such as isolated gate drivers, that support the faster switching needs of newer silicon carbide and gallium nitride power switching technologies.

The benefits of working closely with suppliers who have system-level expertise and a broad portfolio of products goes beyond having access to more sophisticated components and building blocks. It also gives battery manufacturers access to reference designs for system architectures that can be more easily adopted, making time to market three to four times faster than if a battery manufacturer were to develop a formation and test system from scratch.

With the expectation that the global demand for EVs will increase at a CAGR of 21% out to 2021,2 the need for close partnerships between battery manufacturers and suppliers couldn’t be greater. Suppliers need to provide reliable, proven solutions that enable manufacturers’ systems to achieve new levels of efficiency. The best suppliers can help manufacturers bring these new capabilities to market even faster, and the results will allow battery and electric vehicle production to flourish.

About the Author

Vikas Choudhary is strategic marketing manager for battery formation and test products at Analog Devices, based in ADI’s Wilmington, Massachusetts office.

Vikas is responsible for developing product and business strategy in the emerging area of battery formation and test. He has over

20 years of experience in the semiconductor industry including system architecture, technology leadership, and management roles in the areas of RF ICs, high speed interfaces, MEMS, and linear and precision signal processing. He is the editor of the book MEMS: Fundamental Technology and Applications, has five issued patents, and has several journal and conference publications. Vikas has an M.S. degree from UCLA. He can be reached at vikas.choudhary@analog.com.