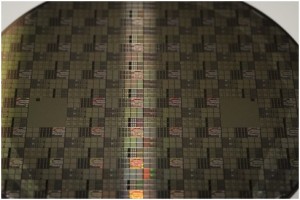

Courtesy: Compound Semiconductor

Manufacturers of high voltage GaN-on-silicon transistors have yet to deliver, but GaN Systems promises a raft of products this year.

Watch this space: GaN Systems intends to commercialise its GaN-on-silicon technology this year.

As industrial, power and communications industries demand semiconductors with faster switching speeds and unbeatable breakdown voltages, manufacturers of GaN-on-silicon devices are getting ready to deliver. Latest forecasts are edging towards a billion dollar market come the end of the decade, and one company keen to cash in, is Canada-based GaN Systems.

“2014 is going to be a pretty big year for GaN Systems,” says company chief executive, Jim Witham. “We’ve just announced our families of 100V and 600V parts, with a nice range from 10A to 80A, we’re getting these into the market place, expanding our presence and gaining customer design wins.”

While GaN Systems is hardly alone in the race to commercialise GaN-on-silicon technology, market-ready high voltage GaN-on-silicon devices have been a long time coming.

Right now design engineers can get their hands on a low voltage GaN-on-silicon HEMT from Efficient Power Conversion, via Digi-Key and International Rectifier has started to ship GaN-on-silicon products. But the only generic 600V GaN-on-silicon HEMT device, publicly introduced by Transphorm, comes with a non-disclosure agreement.

Witham thinks this will soon change. Having recently returned from this year’s Applied Power Electronics Conference – APEC 2014 – in Fort Worth, Texas, he’s excited.

“Several companies already have devices in customers’ hands and at least four companies at APEC were showing devices in their booths,” he says. “A lot of design engineers are now very excited about the prospect of GaN transistors as they know what the technology can do for their systems; they’re saying, ‘let me get these into the lab and run them, then I’m going to design them in and use them’.”

New entries

Jim Witham, formerly chief executive at Neoconix and Fultec Semiconductor, joined GaN Systems only weeks ago, brought in by co-founders Girvan Patterson and John Roberts to take the company’s products to market, this year. Patterson and Roberts founded the company in 2008, after a decade of GaN research, gaining original support from the Ottawa Centres of Excellence for a project with Carleton University, and then capturing funds from clean-tech venture capital firms Chrysalix Energy Venture Capital and RockPort Capital.

From the outset, GaN System’s goal has been to ease the adoption of GaN for design engineers. Researchers have honed the company’s transistor structure, with its distinctive chequered arrangement of source and drain connections, branded ‘Island Technology’, and delivered several patented packaging methods.

‘Island Technology’ promises to ease GaN transistor integration

And as GaN power technology matures and the market readies for rapid growth, the management team is clearly prepping the company for commercialisation. Witham’s very recent appointment comes hot on the heels of Charles Bailley, now senior director of technical marketing, Asia, as well as Tony Astley, appointed as director of European operations.

As Witham puts it: “This year is all about making devices. With our sales and marketing leadership in Japan and Europe, we’re really investing in our sales channels. We want to get out to the [design engineers] and put products into their hands.”

“My background fits exactly with this,” he adds. “I’ve taken new products and done what I call the missionary sell. I take a new technology, explains to the customer why it’s so much better than the existing, [silicon], and then get them to convert over to it.”

Jim Witham: “We want to get out to customers and put products into their hands.”

But converted or not, don’t GaN-on-silicon transistors – at least the high voltage versions – still have some serious hurdles to surmount before true commercialisation? Current collapse, especially at 400V operation and higher has long been a research and development focus in industry and academia. Meanwhile many an oscilloscope manufacturer has highlighted the test and measurement challenges posed by high voltage, high bandwidth GaN devices.

Witham isn’t fazed. “You know, [current collapse] was taken care of years ago. Ten years ago this was a huge issue but researchers have taken care of that,” he says.

“But yes, test equipment design engineers come into GaN Systems quite frequently,” he adds. “These equipment makers have some work to do but this is also an opportunity for them; once these problems are worked out, they will have some new equipment to sell.”