An Interview of Mr. Karsten M. Bier CEO of Recom Group By Electronics Maker.

1. What are the challenges with current packaging design for DC-DC converters?

Power density is one of the most important properties of a modern DC-DC converter design. Shrinking the design requires placing power components closer together. By doing so, you’re placing multiple heat sources near one another, so one of the main challenges current packaging designs face is getting the heat out efficiently. Thermal design considerations in very high density designs becomes crucial.

Another major challenge with any DC-DC converter design is EMC. One way to increase the power density is to shrink the size of the passives by increasing the operating frequency of the converter (faster switching requires smaller component values). But if you do this, the layout of the board often determines if the converter will pass or fail an EMI test. A good way to keep the parasitic elements in a circuit low is to limit the length of connectors on your PCB, but traditional packaging designs have limits to how short these traces can be.

2. What are the benefits of advanced packaging techniques?

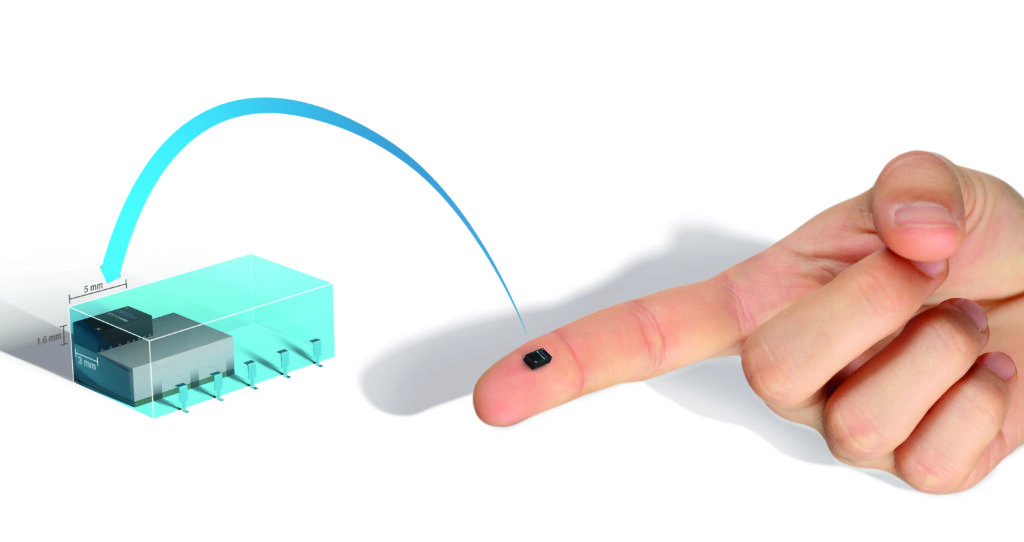

One of the advanced assembly techniques which really help to overcome the challenges of current packaging designs is FCOL (Flip-Chip-On-Leadframe) power components. This technique not only significantly reduces the connection parasitics, but by flipping the IC and placing it directly on a leadframe, the FCOL design also has a dramatically reduced thermal resistance. The assembly technique allows higher switching frequencies to be reached while still meeting strict EMC requirements.

In Recom’s technology, we additionally put active and passive components directly inside the PCB. This achieves similar results to the flip-chip-on-leadframe approach by shortening power paths and reducing the thermal resistance of the design, thereby allowing us to reduce the solution size and increase the performance of the module.

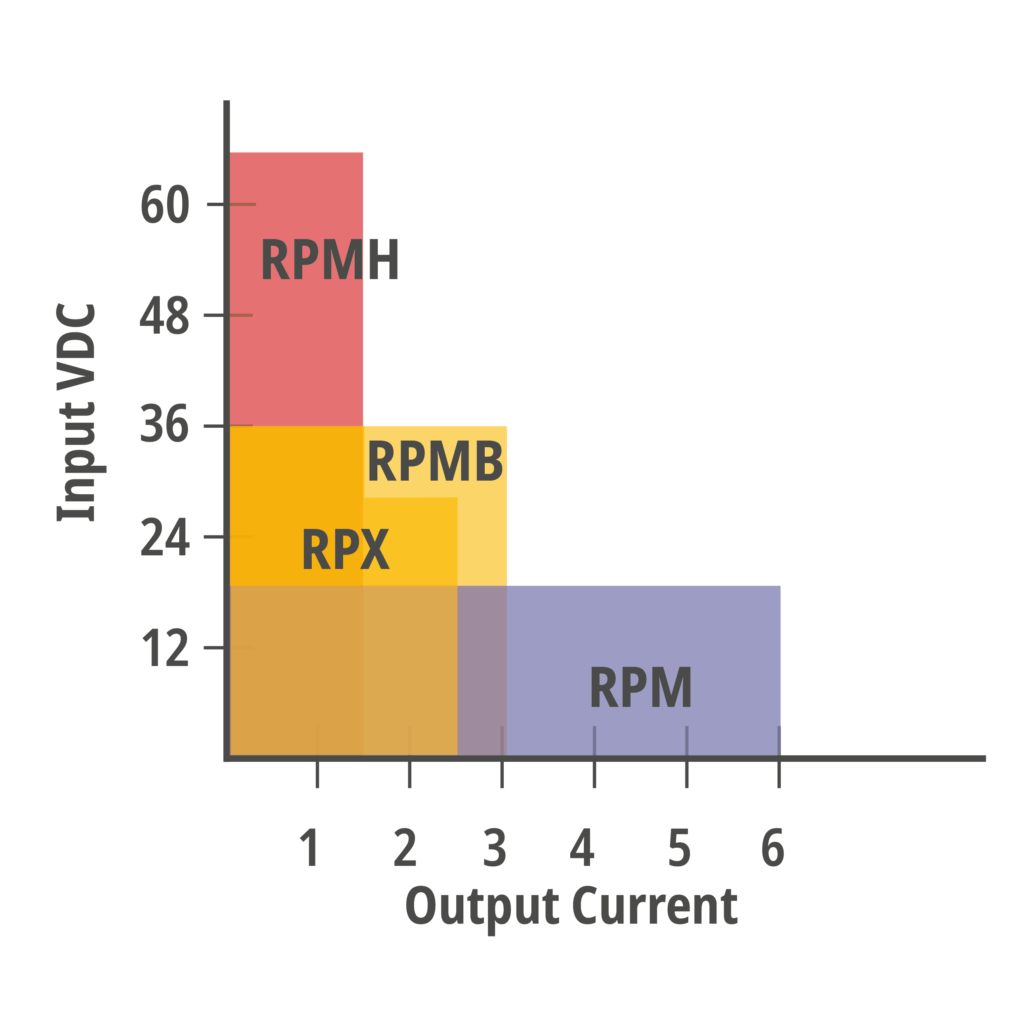

We’re also using different techniques to solve different problems. There is no point making the converter smaller if you can’t manage the heat and the electromagnetic disturbances it then creates. Customers often demand a holistic solution which addresses all thermal, EMC and power performance requirements in a single unit – in other words, they want a plug-and-play solution. For such customers, the RPM series is the way to go. It is a compact module that requires the minimum of external components (for example, two resistors to set the output voltage) to create a complete DC/DC power supply.

3. Please highlight Recom Advanced Packaging technology for low power DC-DC Converters?

Advanced packaging technologies such as 3D power packaging are used in over-molded flip-chip-on-leadframe designs, embedded active and passive components in the PCB, and multi-level designs. This helps Recom to increase power density and raise switching speeds without harming the thermal performance.

4. Tell us about your products leveraging advanced packaging technologies.

The RPM, RPMB, RPMH, and RBB series all use thermally optimized, multilayer PCB technologies with BGA chips and the RPX series incorporates FCOL technologies. And finally, the new RxxCTxxS uses a multi-level design and air-core transformer to reach very high isolation levels in a very low profile, IC-type over-molded package.

INTERESTED IN 3DPP PRODUCTS

FOR FREE SAMPLE

FOLLOW THE BELOW LINK:

https://recom-power.com/en/free-3dpp-india.html

5. The application of product is closely related to the development of industries. Can you share some applications that Recom’s Advanced Packaging technology mainly focuses on?

We are very fortuned that our large product portfolio addresses various customer segments across the industry. The 3D power packaging products suit almost all kinds of applications and fulfil the market requirement of minimize PCB footprint, high power density, fully automated production process, time to market as well as easy to use.

One example is the drone applications (refer to image below), the power module shown in the drone is up to 6A for high power which is good for the battery in drone applications.

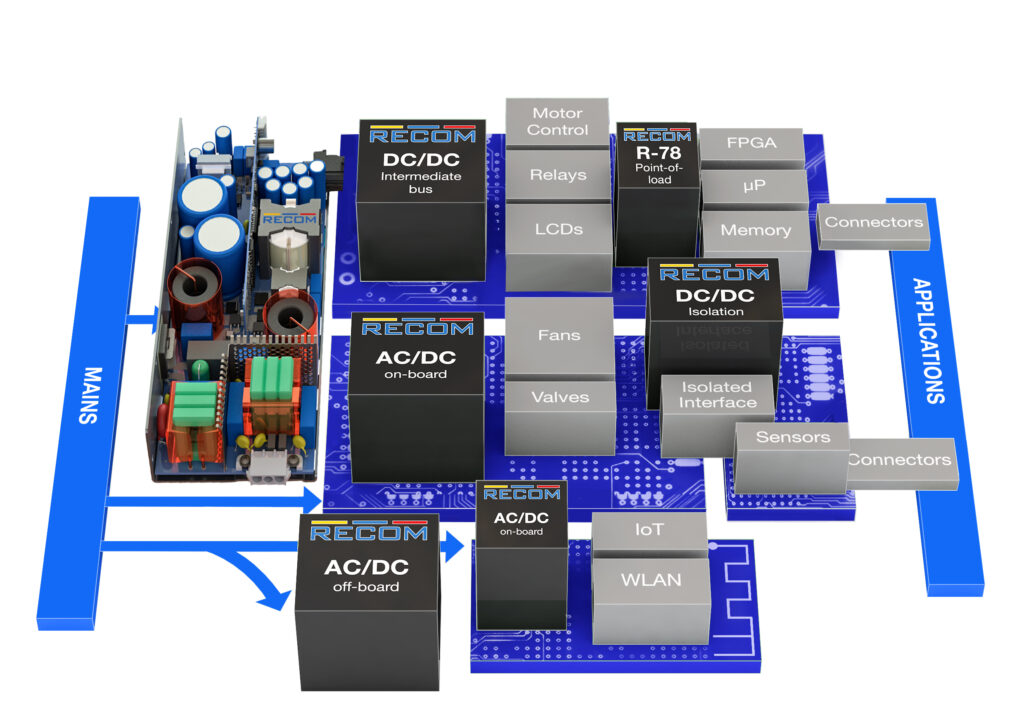

Other applications include Telecom applications, ie set up boxes, gateway for smart metering like 5G, Industrial, Robots, Medical, Mobility, Energy, Automotive, etc.

6. As of the current global pandemic situation, how Recom’s business is going on?

The current pandemic has hit hard in some of the industries like the automotive, aviation and machinery, where we see a decrease in sales coming from there. However, at the same time, the good news for us is that we do see a strong increase in business in the Medical, Mobility, Energy, IoT and 5G applications. Given that RECOM has a wide product portfolio, we can therefore cater exactly to the rising demand coming from these industries.

7. In terms of Sales and Manufacturing how the year 2020 is going for RECOM?

While we had some manageable problems in the procurement of components and the supply chain handling issues, they have limited impact in our overall operations. RECOM’s forward looking preparations has allowed our global design and manufacturing structure remained unaffected and we were able to maintain operations at all manufacturing facilities (Austria, Italy, China Mainland and Taiwan area).

8. What are other products RECOM is planning to launch in power supply?

Recom will continue to innovate in these difficult times. We have several more additions to our power module family set to release next year. We will also continue to grow our high power AC/DC and DC/DC portfolios. With our expansion in Vienna and China and our acquisition in Italy of a company specializing in mobility solutions, Recom is well set up for the future.

To Know more about 3DPP

WATCH THE VIDEO BY BELOW LINK: