Munich (Germany), July 22, 2019 – With its ASM Performance Monitor 2.0 software, ASM SMT Solutions once again underscores its position in the integration and networking of smart electronics production. The newly developed factory monitoring solution provides customers with real-time transparency regarding their smart SMT factory and establishes a valid basis for further improving their productivity, quality and delivery reliability. To do this, the software collects machine data in real time and uses it to determine various KPIs (key performance indicators) that can be analyzed in detail (drilldown). Customers have access to role- and/or task-based views in all areas of the factory as well as remotely and on mobile devices. The Factory Console provides factory or production managers with a quick overview, while the Machine Console and Line Console visualize detailed KPI information for process engineers and operators. In addition to real-time views, the system can generate automatic reports from various aspects. It also features the ability to set threshold values for targets and alarms that trigger automated notifications and escalations.

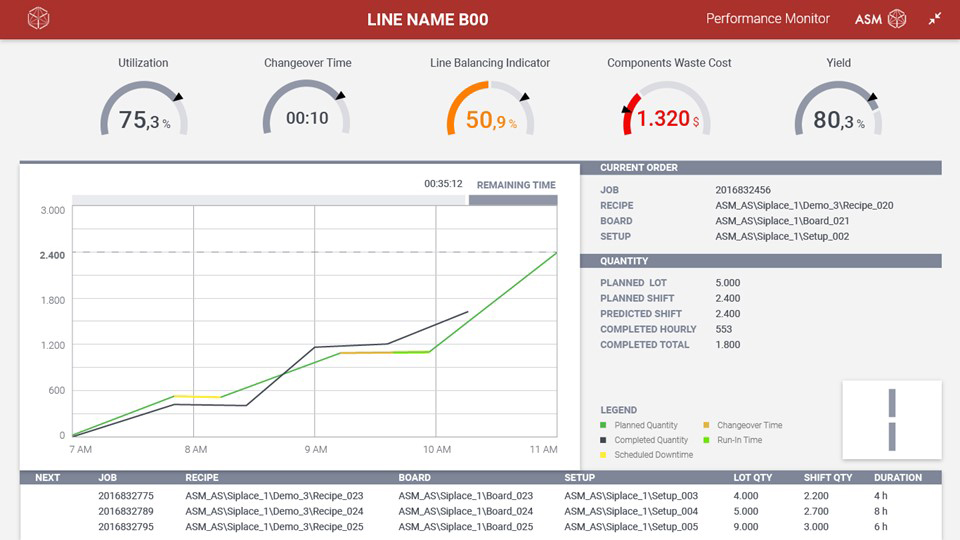

With the Performance Monitor 2.0, technology leader ASM offers another powerful component for modern factory monitoring that features real-time KPIs, drilldown functionalities, mobile access, role-based views, and automated reports and alerts. The new ASM software fits seamlessly into the company’s existing software and equipment landscape. It collects machine data in real time and uses it to compute six central KPIs: Utilization, OEE (overall equipment efficiency acc. to the SEMI standard), OEE benchmark (OEE with regard to the machine’s or line’s theoretical placement performance), component waste rate/cost, changeover time, and yield (after the post-reflow AOI).

With the Performance Monitor 2.0, technology leader ASM offers another powerful component for modern factory monitoring that features real-time KPIs, drilldown functionalities, mobile access, role-based views, and automated reports and alerts. The new ASM software fits seamlessly into the company’s existing software and equipment landscape. It collects machine data in real time and uses it to compute six central KPIs: Utilization, OEE (overall equipment efficiency acc. to the SEMI standard), OEE benchmark (OEE with regard to the machine’s or line’s theoretical placement performance), component waste rate/cost, changeover time, and yield (after the post-reflow AOI).

The ability to drill down from the KPI overview to trend data and detailed views of individual line components with a mouse click makes it easy to identify the causes of deviations from target values and take appropriate countermeasures.

Role- and task-specific views

The ASM Performance Monitor 2.0 provides users with views for their specific jobs and tasks – even remotely and on mobile devices. While the Factory Console supplies production and factory managers with KPIs for the entire production down to individual lines, the Machine Console and Line Console provide process engineers and machine operators with detailed views and analyses of things like output, order progress, and a whole lot more.

To enable users to take instant countermeasures when KPIs miss their targets, the new factory monitoring solution features its own notification functions. Users can define high and low thresholds whose violation triggers automated notifications of groups of people for each KPI. The regular distribution of standard reports can also be automated. The software can analyze and visualize data from up to the last 24 months, and a log function records the reasons for line stops.

No real control without transparency

“Our goal is to implement the smart SMT factory with our integrated solutions. To meet customers’ rising demand in terms of productivity and deliver reliability, you need total transparency regarding everything that happens on the factory floor. Our new factory monitoring solution supplies KPIs that were previously available only with a lot of delay and at great expense, and it can even display them remotely and via mobile device browsers. Thanks to different views, users see only what’s relevant for their particular job duties. Even the time-consuming configuration and distribution of reports is fully automated,” says Theresa Gerhäuser, SMT Solutions Manager at ASM.