Using the Keysight FieldFox All-in-One Analyzer for Precision Validation of Radar System Performance in the Field

Using the Keysight FieldFox All-in-One Analyzer for Precision Validation of Radar System Performance in the Field

Radar systems are used in a multitude of applications, from traffic enforcement to weather prediction. Some of these are mission-critical systems, meaning that any malfunction or failure puts lives at risk. To help ensure favorable outcomes and enhance system uptime, routine maintenance and occasional troubleshooting and repair are essential. All must be done quickly, accurately and dependably, and often in harsh environmental conditions.

The realities of radar installation and maintenance make this difficult. Because mission-critical systems are often highly complex, benchtop-caliber results are needed; however, making accurate measurements in the field using benchtop equipment is not an easy task. Luckily, the breakthrough technologies available in Keysight FieldFox handheld combination analyzers offer system maintainers a new way to test mission-critical radar systems in the field. These analyzers are equipped to handle routine maintenance, in-depth troubleshooting and anything in between. Better yet, FieldFox delivers precise measurements up to 50 GHzvirtually anywhere maintainers need to go.

Radar System Maintenance and Troubleshooting: The Basics

Radar systems fall into several categories such as meteorological, civilian air traffic control and military air defense. A prime example of a widely used mission-critical system is commercial air traffic control. These transmit and receive waveforms—pulsed, unmodulated continuous wave (CW), and FM-CW—that, when processed, provide important information regarding target range, size and shape; velocity and trajectory; azimuth angle and elevation angle; and aircraft identification.

When characterizing and troubleshooting radar systems and components in the field, it is often necessary to measure time-and frequency-domain performance over a variety of test conditions. Given the complexity of today’s systems, maintainers also must coordinate and compare waveforms in both domains. Maintainers may even need to test and tune the various functional blocks or line-replaceable units (LRUs) in the radar system.

Traditionally, such testing has been performed using multiple benchtop instruments. This is especially true at the LRU level, which often requires a set of basic measurements in both the time and frequency domains (e.g., absolute and relative amplitude and phase) and various combinations of those measurements.

Covering all of the necessary measurements often requires three or four separate instruments. For example, a peak power meter is used to measure the absolute amplitude of a transmitter as a function of time, but a spectrum analyzer is needed to measure absolute amplitude as a function of frequency. When performing relative measurements, the peak power meter can measure the relative time and amplitude of a waveform, but a vector network analyzer (VNA) or vector voltmeter is needed to measure amplitude and phase as a function of frequency.

Figure 1 shows the instruments that have typically been used over the past several decades to field-test civilian aviation radars. Because most benchtop equipment is designed for indoor use, the test site must have adequate weather protection to ensure safe, accurate operation.

This traditional approach has several issues. First, the accuracy of benchtop instruments is generally specified by the manufacturer only when operated at a set temperature (e.g., 23±5 degrees C). In the field, testing may occur over a wide range of environmental conditions, causing uncertainty in the measured data.

Second, maintainers often use older benchtop equipment, which becomes difficult to maintain or repair when it goes out of support life. Switching to newer instruments is beneficial in terms of reducing the overall cost-of-test because many have three-year warranties and lower overall maintenance costs. Newer instruments also generally provide higher performance, improved accuracy and application-specific functions. However, one-for-one instrument replacement is not the optimum solution in radar applications.

The All-In-One Analyzer

Today, combination or all-in-one analyzers provide multi-instrument capability and offer the most convenient and economical solution for testing of radar systems. The key to ensuring successful and accurate results is, of course, selecting the appropriate instrument.

FieldFox combination analyzers provide all the measurement capability of the four instruments shown above in Figure 1. With the addition of a peak power sensor, FieldFox provides a solution that can easily be carried to a test site for measuring the time and frequency performance of a radar system (Figure 2). For example, a FieldFox combination analyzer has the functionality needed to test to the LRU level. Supported measurements include full pulse-analysis capability to 40 GHz with a USB peak power sensor and relative timing measurements of the transmitter main to auxiliary pulses. FieldFox analyzers also support stable local oscillator (STALO) phase alignment through the vector voltmeter mode.

Utilizing Field-Ready Technology

The FieldFox combination analyzers are specifically designed for field testing with a 3.5-hour battery life, 7.1pound weight and built-in GPS. The rugged, fully sealed enclosure—no fans or vents—is compliant with US MIL-PRF-28800F Class 2 requirements and is type tested to meet MIL-STD-810G Method 511.5, Procedure 1 requirements (operation in explosive environments). FieldFox is also type tested to meet IEC/EN 60529 IP53 requirements for protection from dust and water, extending instrument durability in even the harshest environments.

FieldFox analyzers also support remote operation through an application that runs on a variety of Apple iOS devices. This is ideal for test environments in which it may be difficult to control and observe the analyzer while simultaneously operating some part of the radar system.

Comparable benchtop instruments are specified to operate at a set temperature and require lengthy warmup times. In contrast, FieldFox features an automatic internal alignment function in its spectrum analyzer mode that compensates for temperature changes over a range of -10 to +55°C. With this InstAlign feature, the analyzer is ready to make highly accurate spectrum measurements at turn-on and through any temperature changes over the specified range.

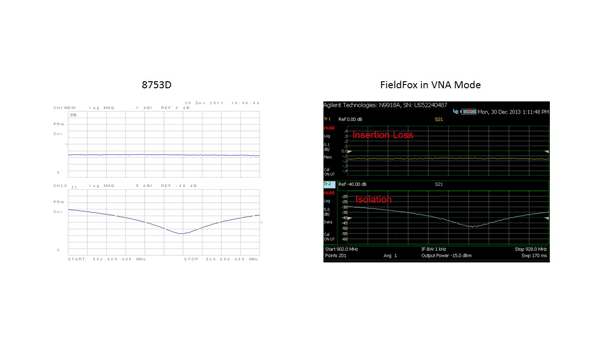

Equally important, FieldFox time-and frequency-domain measurements have been shown to correlate with benchmark data taken in the development lab using benchtop instruments, and at system installation (Figures 3 and 4). FieldFox achieves S-parameter results that track the world’s highest performance VNA within a few hundredths of a dB, and match the world’s highest performance spectrum analyzer within tenths of a dB. This level of correlation increases confidence in measured results and also reduces the risk of passing bad LRUs or failing good ones.

Reducing Maintenance Costs

A key benefit of using modern, field-ready technology is a reduction in overall capital and operating expenditures. For example, a single FieldFox combination analyzer can replace all four RF instruments traditionally used for civilian radar test in the field, and it’s typically one-third the cost of a single, comparable benchtop instrument. Moreover, it requires just one calibration per year, reducing annual costs by a factor of up to five compared to the traditional approach, which requires four calibrations per year plus calibrations of spare instruments.

FieldFox has the lowest failure rate of any complex microwave or millimeter-wave instrument from Keysight. In fact, FieldFox offers the highest reliability of any complex RF, microwave and millimeter-wave instrument, and this reduces the overall test cost by at least 50% versus comparable benchtops. A standard three-year warranty also reduces the overall repair cost.

Because FieldFox analyzers are neither outdated nor anywhere near the end of their support life, there is little need to maintain spare parts or spare instruments, both of which significantly add to the overall cost-of-test.

Conclusion

Maintaining complex mission-critical radar systems has traditionally required maintainers to use benchtop equipment. This was the only way to ensure accurate and repeatable radar measurements.

With the accuracy and functionality of the FieldFox combination analyzers, radar maintainers working onsite now have an easier, more cost-effective way to perform precise performance validation, maintenance and repair. This dramatically reduces the cost-of-test and also increases the uptime of mission-critical systems.