Helping industrial equipment stay healthy

Authors

Chandrappa Niranjan : Product applications engineer in the Energy Management Group at Analog Devices

Swarnab Banerjee : System engineering manager in the Energy Management Products Group of Analog Devices. He is responsible for addressing the growing technology needs for power delivery and power conversion equipment that target the smart grid

According to a recent study published by the Electric Power Research Institute (EPRI), large industrial facilities in the US lose over $100 billion every year due to power problems including power supply variations and voltage disturbances. When the lights flicker at home, it’s an annoyance. But when power is disturbed at a factory, it can cause malfunction and early breakdown of expensive equipment. Oftentimes, subtle power quality events pass through traditional protection networks undetected and contribute to equipment degradation over time. Furthermore, the source of many power quality disturbances are the loads connected to the same network causing disturbances to propagate through adjacent facilities and buildings.

According to a recent study published by the Electric Power Research Institute (EPRI), large industrial facilities in the US lose over $100 billion every year due to power problems including power supply variations and voltage disturbances. When the lights flicker at home, it’s an annoyance. But when power is disturbed at a factory, it can cause malfunction and early breakdown of expensive equipment. Oftentimes, subtle power quality events pass through traditional protection networks undetected and contribute to equipment degradation over time. Furthermore, the source of many power quality disturbances are the loads connected to the same network causing disturbances to propagate through adjacent facilities and buildings.

In order to overcome power quality challenges, it is necessary to monitor inputs and disturbances generated by the load. Power quality monitoring can provide appropriate protection to equipment and can help identify suitable mitigation techniques that improve power quality. If stakeholders take full advantage of the technology, their expensive infrastructure will benefit from clean power and an extended life.

Power quality is a term that refers to a wide variety of variations in the electric power supplied to utility customers. It can cover wiring problems, grounding issues, switching transients, load variations, and harmonic generations. In some cases, poor power quality can go undetected yet damage expensive equipment. In Europe, the quality of electricity that is provided by a grid operator is defined by the reference parameters set in the national grid codes and the European standards (EN 50160).

When the supply voltage is distorted, a device draws non-sinusoidal currents and it can cause many technical problems such as overheating, malfunction, and premature aging. The non-sinusoidal current also causes thermal and insulation stress on network devices such as transformers and feeder cables. Poor power quality ultimately results in financial losses caused by equipment downtime, increased maintenance activities and shorter life times. In this article the impacts of poor power quality will be analyzed from the perspective of industrial equipment and how to maximize machine health.

Where do power quality disturbances originate?

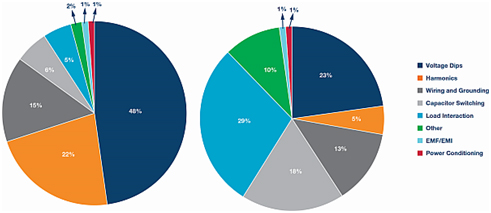

The left side of Figure 1 summarizes a study that the Electric Power Research Institute conducted for distribution power quality among 24 utilities throughout the USA. The majority (85%) of power quality incidents originate from voltage dips or swells, harmonics, and wiring and grounding problems. The other half of Figure 1 shows the results of a European Power Quality survey which estimated that power quality problems in EU-25 countries create financial loss of more than $156B per year (€150B). In industrial settings, starting and stopping of heavy loads can result in voltage sags and swells that move the network voltages outside the standard operating condition.

As most equipment is designed to operate within a certain operating condition, prolonged voltage dips and swells result in shut downs and process outages. In today’s business climate, many companies are considering or already installing locally generated renewable energy sources such as solar and wind. In many cases, distributed generation sources introduce a need for switch mode power supplies in electrical installations. With the increased adoption of power electronics and switching power supplies, harmonics will become a more common source of power quality problems in industrial equipment.

These types of power supplies can inject harmonics on electrical lines and degrade power quality so that everything tied to the supply network is impacted including transformers and cables. Oftentimes facility managers can observe impacts of large harmonic currents as the network components get overloaded. In some cases, increase in total losses of 0.1% to 0.5% on network components can cause tripping of protection devices. Some other occurrences that can contribute to poor power quality include differential loading of phases, incorrect wiring and grounding schemes, load interactions, EMI/EMC and switching of large reactive networks.

Power quality standards

In order to cope with and manage power quality, one must find a reliable monitoring and reporting method. Some of the key standards created by industry are IEC 61000-4-30 Class A and Class S, IEC61000-4-7 Harmonic measurements and IEC61000-4-15 for Flicker. Most utilities have adopted these power quality standards to develop and enforce regulations. In certain cases, utilities may penalize a customer if power quality standards do not meet regulations.

Industry standards not only establish a common understanding of power quality in real-world applications but they also give users confidence they will have accurate data to solve problems and issues related to events. In electrical networks, voltage sags, swells, flicker, variation in nominal ratings, distortion due to harmonics, all contain the key information regarding the electrical health of the network. Measurement accuracy is the key to providing reliable and repeatable results.