Micro-Measurements Introduces New Small-Scale Strain Gages Designed Specifically for PCB Reliability Testing

MALVERN, Pa. — July 7, 2015 — Micro-Measurements®, a Vishay Precision Group, Inc. (VPG) brand, today launched three new small-scale strain gages designed to meet the growing demand for precise, stable, and reliable stress analysis of PCBs, even in harsh environments. The C2A-06-G1350-120 rectangular rosette gage and C2A-06-015LW-120 uniaxial linear gage are designed to detect PCB surface strains at critical locations in consumer electronics.

The miniaturization of consumer electronics — and consequent increase in component density — results in larger thermal stresses, new requirements for surviving repeated loadings, and a greater need for impact stress survival. Meeting these specifications requires accurate knowledge of strains in the PCB and on-board components. Strain gage measurement is the quickest, most accurate, and most cost-effective method for identifying strains on a PCB, and it can be used in developing loading fixtures and test plans to optimize the testing phase.

The miniaturization of consumer electronics — and consequent increase in component density — results in larger thermal stresses, new requirements for surviving repeated loadings, and a greater need for impact stress survival. Meeting these specifications requires accurate knowledge of strains in the PCB and on-board components. Strain gage measurement is the quickest, most accurate, and most cost-effective method for identifying strains on a PCB, and it can be used in developing loading fixtures and test plans to optimize the testing phase.

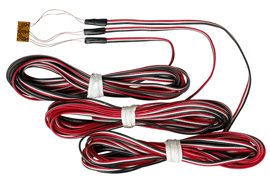

The C2A-06-G1350-120 is a stacked rosette gage with a compact 5 mm diameter matrix and 3 meters of three-conductor cable to eliminate lead wire soldering after bonding. Micro-Measurements’ Advanced Sensors strain gage technology makes even smaller planar rosettes possible for use in surface mounting applications with restricted areas, as well as for intra-laminar strain measurement. The uniaxial linear C2A-06-015LW-120 is supplied with pre-attached cables and features an active grid length of just 0.015 in and an overall matrix of 1.4 mm by 1.9 mm. The device is ideal for installation on surface-mount components.

“Cracks in the PCB and even across components, particularly around BGAs, can be induced by in-circuit test fixtures and during assembly, burn-in and testing, system integration, and packaging and shipping,” said Bob Watson, Micro-Measurements director of research and development. “Strain measurements should be made after all design iterations of the PCB, including changes to on-board components, which may alter thermal stress loading. Combined with Micro-Measurements instrumentation and StrainSmart software, our strain gages and accessories for PCB testing are IPC/JEDEC-9704-compliant and provide real-time data acquisition of board and component strains. This is especially useful when introducing new solder materials and processes, which may have a different stiffness and introduce a different soldering thermal profile.”

Samples and production quantities of the new PCB strain gages are available now, with lead times of six weeks for prototype samples and 11 weeks for standard orders.

Further information about Micro-Measurements strain gages and technical support is available at www.micro-measurements.com. Follow Micro-Measurements at www.strainblog.com or twitter.com/strain_gage.