Courtesy: Keithley Instruments

Particularly for the new generation users, electronics test and measurement manufacturers focus their efforts on creating user-friendly, modern tools.

Over the past decade, significant changes have been underway among users of electronic test and measurement instrumentation. For example, electronics companies’ R&D staffs have shrunk, and engineers report they are under pressure to do more with fewer resources than in the past. At the same time, there are fewer engineers dedicated to test with in-depth test and measurement training and background. This means there are fewer engineers focusing on getting accurate measurements in the most efficient way possible. In addition to the traditional electrical engineer user, today’s users increasingly come from backgrounds like materials engineering, electrochemistry, biotechnology and physics, who often have limited experience in configuring electrical measurements or who only occasionally borrow an instrument from another department.

One in five electrical engineers now on the job has started his or her career within the last decade. This has a number of ramifications. For example, these younger engineers tend to be more software-oriented than hardware-oriented. This challenge is compounded by growing time-to-market pressure as design cycles continue to shrink. All of these factors are imposing heavier time and financial burdens on test instrument users and their employers.

Until relatively recently, interacting with instruments was typically anything but a seamless process. For those who used instrumentation a few decades ago, taking data often required manually transcribing readings from an analog dial (Figure 1) or using a ruler to measure traces from a strip chart recorder printout.

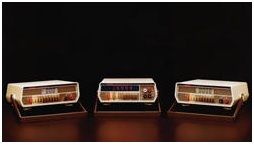

ight-emitting diode (LED) and liquid-crystal display (LCD) digital readout displays and push-button control interfaces, represented the first substantial interface innovations for local (on-instrument) measurement configuration (Figure 2). The first communications interfaces (including RS-232 and GPIB) were soon added to instruments to support system integration and triggering, remote programming and control, as well as transfer of data to external controllers for analysis and display.

In the 1990s, users began to demand further detail on their measurements, such as the level of current sourced to the device under test, voltage limits and error messages. This demand eventually led vendors to begin developing brighter, easier-to-read, multiline vacuum fluorescent displays that could display multiple measurements simultaneously from a single measurement connection. This new display capability also made it possible to present measurement results in more intuitive ways, such as bar graphs. To allow users to configure the display settings and performance options, vendors often assigned multiple functions and performance options to the same front panel button.

More recently, some graphical user interface (GUI) designers adopted a soft-key interface and display approach to simplify the control menu structure. Although this is a step toward more intuitive operation, this approach still requires navigating through multi-level menu structures.

However, within the last few years, a growing number of vendors have gotten serious about taking evolving user characteristics and expectations into account in their interface designs. Vendors, when they have a new product concept, solicit input from customers so they can understand not just what customers want today, but also what they’ll need five years from now. This helps bring their products to market faster. Trends indicate test engineers want instrumentation interfaces that are intuitive enough to operate without having to review a manual and that can take quick measurements at the press of a button. These demands for more intuitive operation and faster answers are driving much of the new thinking behind the next generation of electronic test instrument design.

Today, younger engineers’ expectations come from being immersed in a world filled with consumer electronics with advanced touchscreen interfaces like tablet computers and smartphones. These influences are now shaping their attitudes about the instrumentation they use on the job. For these users, new test instruments will increasingly offer GUIs that simplify test setup and present results in a way that’s easy to interpret. Their operation will be more intuitive to minimize the learning curve for infrequent or novice users and to maximize productivity. The ability to deliver accurate measurements is still absolutely necessary, but today’s users are also looking for instruments that allow them to learn faster, work smarter and invent easier.