![]() If electric vehicles are undoubtedly the future of automotive, it will take ingenuity and new technologies to transition from expensive models and proof of concepts to mass adoption and market saturation. One of those breakthroughs takes the form of Silicon Carbide (SiC) and STMicroelectronics leads the industry with high-voltage devices that have already proven essential in designing smaller, lighter and more efficient products that will support the adoption of electric cars on a large scale.

If electric vehicles are undoubtedly the future of automotive, it will take ingenuity and new technologies to transition from expensive models and proof of concepts to mass adoption and market saturation. One of those breakthroughs takes the form of Silicon Carbide (SiC) and STMicroelectronics leads the industry with high-voltage devices that have already proven essential in designing smaller, lighter and more efficient products that will support the adoption of electric cars on a large scale.

Si vs. SiC: It’s All About the Bandgap

Silicon Carbide is a material made of silicon (Si) and carbon (C) atoms organized in a lattice. It has long been known to operate in high-temperature, high-power, high-frequency, and high-radiation environments, thanks to its wide bandgap. To understand the properties of wide-bandgap materials, we must dive into solid state physics. Solids are made out of atoms, which, if we take the most simplistic approach, are made out of a nucleus and one or more electrons.

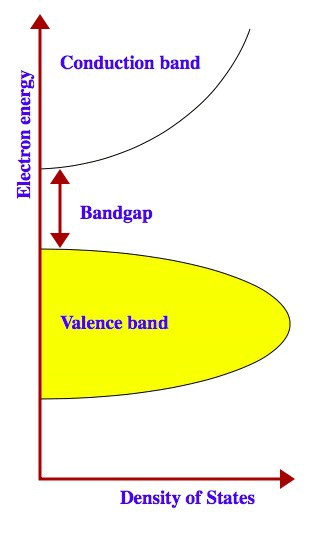

According to band theory, electrons in a solid have two basic energy states that are described by two bands. Electrons with low energy are in the valence band and electrons with high energy are in the conduction band. In a conductor, the valence and conduction bands overlap, and when electrons are stimulated by an applied current, they move from the valence to the conduction band. However, those two bands don’t always overlap and when they don’t the region between them is called the bandgap. The size of the bandgap (measured in electron volts or eV) will determine the properties of the solid. For instance, any material with a bandgap of more than 9 eV is considered an insulator, because such a big bandgap won’t allow electrons to move from the valence to the conduction band at ambient temperatures.

According to band theory, electrons in a solid have two basic energy states that are described by two bands. Electrons with low energy are in the valence band and electrons with high energy are in the conduction band. In a conductor, the valence and conduction bands overlap, and when electrons are stimulated by an applied current, they move from the valence to the conduction band. However, those two bands don’t always overlap and when they don’t the region between them is called the bandgap. The size of the bandgap (measured in electron volts or eV) will determine the properties of the solid. For instance, any material with a bandgap of more than 9 eV is considered an insulator, because such a big bandgap won’t allow electrons to move from the valence to the conduction band at ambient temperatures.

Silicon semiconductors have a bandgap of 1.1 eV. This means they are insulators by design, but their bandgap is small enough that, at room temperature, electrons can jump from the valence to the conduction band when a relatively small amount of energy is applied. By contrast, Silicon carbide is defined as having a bandgap between 2 eV and 7 eV[1], depending on its structure, and most common wafers use a SiC with a bandgap of about 3 eV. This difference of about 2 eV between Si and SiC has tremendous repercussions. At room temperature, the breakdown field of SiC is five times higher than its Si counterpart, and its thermal conductivity is more than three times higher.[2] In a nutshell, this means that SiC devices can tolerate much harsher conditions, far higher voltages, and temperatures, and offer greater performance, than similar-sized Si components.

The first SiC LED was identified in 1907[1] and the first commercially available SiC wafer dates back to 1991. The material is not new, its formidable properties are well-known, but SiC devices remain difficult to produce on a massive scale because they are harder to manufacture than Si components and defects occur much more frequently. Hence, by releasing a whole family of devices rated at high voltages, STMicroelectronics not only leads the industry in the adoption of this long-sought-after material, but shows mastery in processes that have been at the center of scientific research for decades.

A New Reality for Consumers

Recently, STMicroelectronics announced the availability of three devices. The STPSC20065-Y is a high-voltage power Schottky diode with a 650 V rating. This is a massive improvement from Silicon Schottky diodes that are typically limited to 200 V. Schottky devices rectify alternating current and offer fast switching and SiC Schottky devices provide virtually zero recovery time. Their design optimizes performance and reduce the form factor of power supplies and inverters.

Similarly, the STPSC10H12 is a power Schottky rectifier rated at 1,200 V. It displays the same advantages as the Schottky diode mentioned above and the fact that it uses Silicon Carbide means it demonstrates excellent performance in hard switching conditions.

Similarly, the STPSC10H12 is a power Schottky rectifier rated at 1,200 V. It displays the same advantages as the Schottky diode mentioned above and the fact that it uses Silicon Carbide means it demonstrates excellent performance in hard switching conditions.

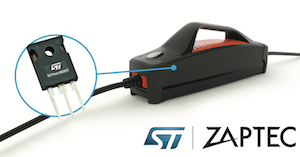

Finally, the SCTW100N65G2AG is a power MOSFET with very good switching performance, and is designed for automotive applications.

Those devices enable the creation of smaller and better components that further the advancements of electric vehicles. One concrete example is the ZapCharger Portable, the smallest electric-car charging station. Using ST’s SiC MOSFET, the charger is 10 times lighter and smaller than similar models, it has an energy efficiency of 97 %, and can work on any electrical car, and on any grid. Range anxiety is no longer an issue when you can charge your electric car anywhere, anytime. And more breakthroughs like these are now possible, thanks to the new Silicon Carbide devices from STMicroelectronics.