Novel Quick Buck BoosterⓇ technology improves system stability in start-stop vehicle systems

*ROHM October 25, 2018 study

ROHM has recently announced the availability of a buck-boost power supply chipset that provides the lowest current consumption in the industry along with stable performance (transient response characteristics) in automotive ECUs (Electronic Control Units) for cluster panels and gateways used in start-stop vehicle systems.

ROHM has recently announced the availability of a buck-boost power supply chipset that provides the lowest current consumption in the industry along with stable performance (transient response characteristics) in automotive ECUs (Electronic Control Units) for cluster panels and gateways used in start-stop vehicle systems.

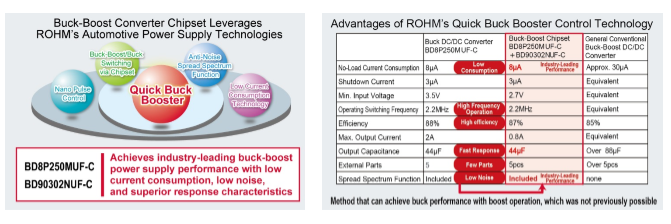

The chipset integrates a buck DC/DC converter with boost functionality (BD8P250MUF-C) and a dedicated boost IC (BD90302NUF-C). The primary chip (BD8P250MUF-C) utilizes ROHM’s novel buck-boost control technology, dubbed Quick Buck Booster, that enables configuration of a buck-boost power supply without degrading buck power supply characteristics by simply adding the dedicated BD90302NUF-C boost IC to the subsequent stage.

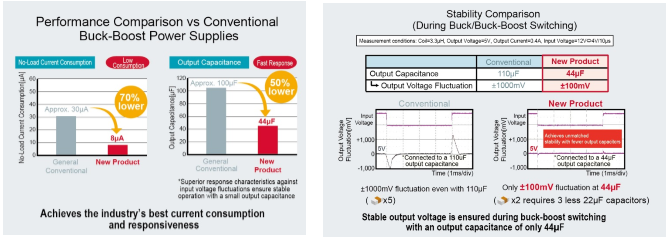

The result is an industry-best no-load current consumption of 8uA and ±100mV output voltage fluctuation utilizing an output capacitance 44uF (70% less current consumption and 50% less output capacitance vs conventional products), contributing to improved stability and energy savings in applications where significant input voltage drops occur in a short period of time, such as start-stop vehicle systems. In addition, Quick Buck Booster technology allows for a common board design that integrates both buck-boost and buck power supply topologies along with the requisite peripheral components and noise countermeasures, reducing development time and labor by 50% compared to conventional methods requiring separate buck-boost and buck power supply boards.

In recent years, to meet the greater environmental performance demanded in the automotive sector, the number of vehicles equipped with start-stop functionality that turns the engine/motor OFF while idle has grown significantly. In these systems, a buck-boost power supply is required to prevent malfunctions due to low battery voltage during idling and battery fluctuations (cranking) immediately after start-stop operation, but conventional products are problematic from the standpoint of current consumption and responsiveness, increasing the demand for an improved solution as the number of stop-start vehicles continues to rise.

In recent years, to meet the greater environmental performance demanded in the automotive sector, the number of vehicles equipped with start-stop functionality that turns the engine/motor OFF while idle has grown significantly. In these systems, a buck-boost power supply is required to prevent malfunctions due to low battery voltage during idling and battery fluctuations (cranking) immediately after start-stop operation, but conventional products are problematic from the standpoint of current consumption and responsiveness, increasing the demand for an improved solution as the number of stop-start vehicles continues to rise.

In response, ROHM leveraged analog design technology and power system processes to develop groundbreaking solutions for the automotive market, such as products that integrate Nano Pulse Control high speed pulse control technology. This time, ROHM developed a buck-boost power supply chipset utilizing proprietary automotive technology centered on Quick Buck Booster control that overcomes the issues related to start-stop systems. And going forward, ROHM will continue to support the evolution of vehicles by developing products and technologies that contribute to greater power savings and system optimization.

Key Features

- Achieves the industry’s best current consumption and responsiveness

The BD8P250MUF-C buck DC/DC converter integrated in ROHM’s chipset utilizes Quick Buck Booster control technology developed by leveraging proprietary analog design expertise, making it possible to easily switch to buck-boost operation without degrading buck performance which features superior characteristics over buck-boost.

As a result, an output voltage fluctuation of ±100mV is achieved at a no-load current consumption of 8uA and 44uF output capacitance even in buck-boost configuration, making it the industry’s best buck-boost power supply (70% lower current consumption and 50% smaller output capacitance vs conventional products), contributing to greater energy savings and stability in a range of applications while reducing both the size and cost of the output capacitors.

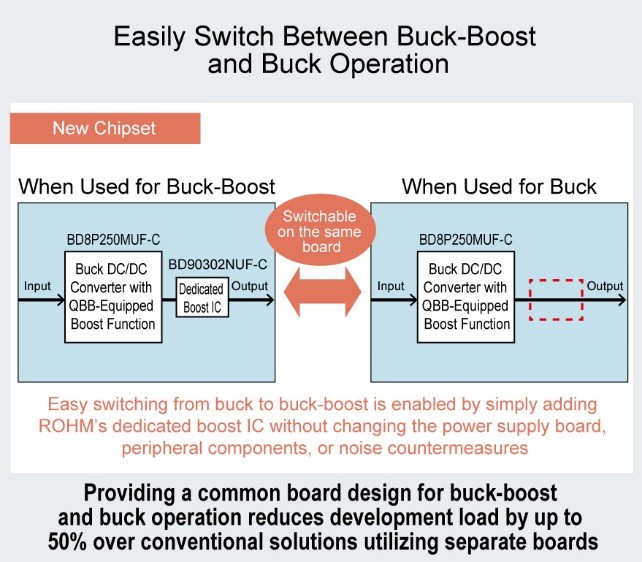

ROHM’s chipset with Quick Buck Booster technology makes it possible to provide a common design that combines both buck and buck-boost power supply operation on a single board along with the requisite peripheral components and noise countermeasures.

ROHM’s chipset with Quick Buck Booster technology makes it possible to provide a common design that combines both buck and buck-boost power supply operation on a single board along with the requisite peripheral components and noise countermeasures.

This makes it easy to switch from buck to buck-boost operation by simply adding a dedicated boost IC, reducing design load by as much as 50% compared with conventional methods utilizing separate power supply boards.

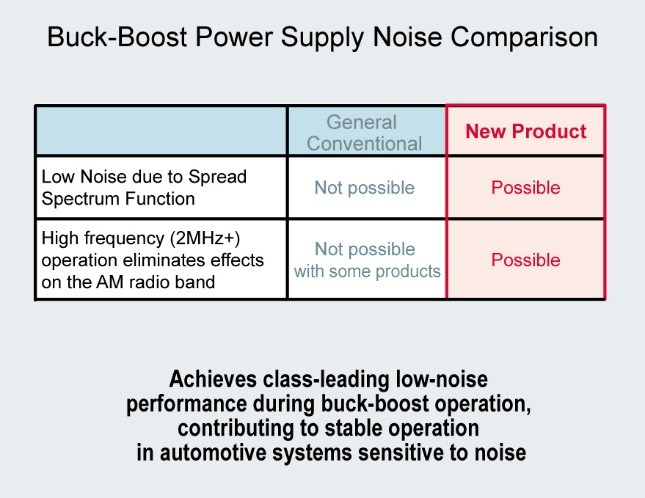

To meet market demands, the BD8P250MUF-C integrates a spread spectrum function as a countermeasure against noise (EMI), allowing it to clear the international standard (CISPR 25) for noise in the automotive sector. At the same time, ROHM’s original ultra-high-speed pulse control technology Nano Pulse Control is utilized to enable high speed operation at 2.2MHz that eliminates the effects on the AM radio band (1.84MHz max.), making it possible to achieve stable 5V output for ECU drive from high-voltage 36V input. This ensures low electromagnetic interference while enabling low voltage output from high voltage input without AM radio band interference, contributing to stable operation in automotive systems sensitive to noise.

Availability: September 2018 (samples), January 2019 (OEM quantities)

Quick Buck Booster Technology

ROHM’s buck-boost control technology developed using proprietary analog design expertise. This allows users to easily switch to buck-boost operation without sacrificing the performance advantage buck DC/DC converters provide over buck-boost power supplies. Implementing a buck-boost topology while maintaining the same characteristics as buck power supplies reduces the size of peripheral components along with development load, contributing to system optimization and stable operation in applications where sudden voltage drops occur, such as ECUs used in start-stop vehicle systems.

| Topology | Part No. | Input Voltage Range | Output Voltage | No-Load Current Consumption | Output Voltage

Accuracy |

Operating Frequency | Max. Output Current | Operating Temperature Range |

| Buck-Boost | BD8P250MUF-C | 2.7V to 36V | 5V | 8µA (typ.) | ±2% | 2.2MHz | 0.8A | -40℃ to 125℃ |

| BD90302NUF-C | ||||||||

| Buck | BD8P250MUF-C | 3.5V to 36V | 5V | 8µA (typ.) | ±2% | 2.2MHz | 2.0A | -40℃ to 125℃ |

Specifications

Terminology

DC/DC Converter (Buck, Boost, Buck-Boost)

A type of power supply IC that converts one DC voltage to another. In general, there is a step-up type (boost) for increasing the voltage and step-down (buck) that reduces voltage. Buck-boost converters can switch between step-up and step-down operation based on input voltage, but due to redundant circuitry they suffer from poor responsiveness and current consumption.