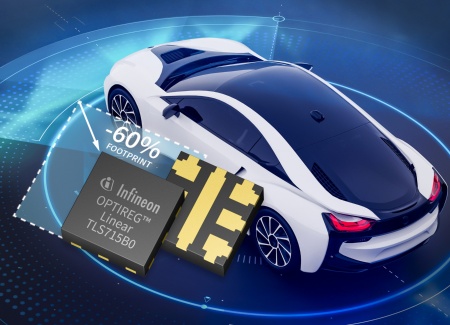

Munich, Germany – 23 January 2020 – Infineon Technologies AG (FSE: IFX / OTCQX: IFNNY) is taking the next step towards smallest power supply devices for automotive electronics. As first chipmaker, the company set up a dedicated production process for flip-chip packages that is fully aligned with the high quality requirements of the automotive market. Infineon now launches the first respective product: the linear voltage regulator OPTIREG™ TLS715B0NAV50.

With flip-chip technology, the ICs are installed upside down in the package. With the heated part of the IC facing the bottom of the package and being closer to the PCB, thermal inductance can be improved by a factor between 2 and 3. The higher power density enables a significantly smaller footprint than conventional package technologies.

With flip-chip technology, the ICs are installed upside down in the package. With the heated part of the IC facing the bottom of the package and being closer to the PCB, thermal inductance can be improved by a factor between 2 and 3. The higher power density enables a significantly smaller footprint than conventional package technologies.

The footprint of Infineon’s new linear voltage regulator (TSNP-7-8 package, 2.0 mm x 2.0 mm) is more than 60 percent smaller than that of an established reference product (TSON-10 package, 3.3 mm x 3.3 mm) while the thermal resistance stays the same. This makes the new device particularly suitable for applications with very limited board space, such as radar and cameras. The OPTIREG TLS715B0NAV50 provides 5 V with a maximum output current capability of 150 mA.

Flip-chip technology has been used in consumer and industrial markets for several years. Due to increasingly strict space requirements, particularly in the growing number of radar and camera systems, also automotive electronics require smaller power supply solutions – albeit with much higher quality requirements. In order to offer best-in-class flip-chip quality Infineon does not rely on a subsequent qualification of existing consumer and industrial products but rather on a dedicated production process for automotive devices.

In the future, flip-chip technology will strengthen Infineon’s overall portfolio of automotive power supply products in the OPTIREG family. The chipmaker is planning to apply it also to its switch mode voltage regulators and power management ICs.