October 8, 2020, New Delhi – As electric motors proliferate across a growing range of system applications, developers need products and tools that ensure systems run as efficiently as possible while reducing board size, component count and energy consumption. Microchip Technology Inc. (Nasdaq: MCHP) today announced it has expanded its motor control offering with digital signal controllers (DSCs) and microcontrollers (MCUs) that are supported by design tools, development hardware, a torque-maximizing algorithm and a refrigerator compressor reference design.

“New products like Microchip’s dsPIC33C DSC devices with their high analog integration demonstrate our continued investment in simplifying motor control system design while reducing development and bill of materials costs in automotive, industrial, medical and consumer applications,” said Joe Thomsen, vice president of Microchip’s MCU16 business unit. “Our newly enhanced support ecosystem helps engineers get their designs done faster with the optimum combination of performance, efficiency and reliability.”

Microchip’s motor control family additions include:

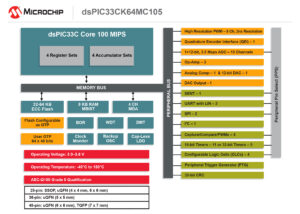

dsPIC® DSCs: The cost-optimized, functional safety-ready dsPIC33CK64MC10x DSCs for Field Oriented Control (FOC) motor control are supported by motor control Plug-in Modules (PIMs) for existing motor control development boards and also with a new cost-effective low-voltage motor control development board. MPLAB® X Integrated Development Environment (IDE) and MCC support rapid code development while motorBench® Development Suite provides FOC motor control optimized code generation.

dsPIC® DSCs: The cost-optimized, functional safety-ready dsPIC33CK64MC10x DSCs for Field Oriented Control (FOC) motor control are supported by motor control Plug-in Modules (PIMs) for existing motor control development boards and also with a new cost-effective low-voltage motor control development board. MPLAB® X Integrated Development Environment (IDE) and MCC support rapid code development while motorBench® Development Suite provides FOC motor control optimized code generation.  PIC32MK MCJ and MCM MCUs for FOC motor control: The second-generation 32-bit MCU devices offer 32-bit floating point and DSP performance with flexible communications options. By sharing analog features with the dsPIC33CK, they support seamless migration across device classes. These devices also feature multiple CAN-FD and USB ports. The MCUs are supported in the MPLAB® X Integrated Development Environment (IDE) with three development hardware options. Software support for the PIC32MK includes a suite of motor control software for sensored and sensorless applications via the MPLAB® Harmony v3 Software Framework.

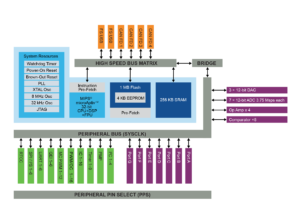

PIC32MK MCJ and MCM MCUs for FOC motor control: The second-generation 32-bit MCU devices offer 32-bit floating point and DSP performance with flexible communications options. By sharing analog features with the dsPIC33CK, they support seamless migration across device classes. These devices also feature multiple CAN-FD and USB ports. The MCUs are supported in the MPLAB® X Integrated Development Environment (IDE) with three development hardware options. Software support for the PIC32MK includes a suite of motor control software for sensored and sensorless applications via the MPLAB® Harmony v3 Software Framework.  motorBench development suite: Version 2.35 of Microchip’s GUI-based software development tool shortens the time required to spin a motor using FOC and generates optimized source code customized for a given motor. This release expands dsPIC33CK family support, adds a new Angle Track-Phase Locked Loop (AT-PLL) estimator, Field Weakening (FW), Maximum Torque Per Amp (MTPA), Dead-Time Compensation (DTC) and many other new features.

motorBench development suite: Version 2.35 of Microchip’s GUI-based software development tool shortens the time required to spin a motor using FOC and generates optimized source code customized for a given motor. This release expands dsPIC33CK family support, adds a new Angle Track-Phase Locked Loop (AT-PLL) estimator, Field Weakening (FW), Maximum Torque Per Amp (MTPA), Dead-Time Compensation (DTC) and many other new features.  Zero Speed/Maximum Torque (ZS/MT) algorithm: Eliminates hall sensors in applications demanding high torque at standstill or low speeds for low-inductance motors. Support is provided for the dsPIC33 DSCs, SAM and PIC32MK motor control MCUs

Zero Speed/Maximum Torque (ZS/MT) algorithm: Eliminates hall sensors in applications demanding high torque at standstill or low speeds for low-inductance motors. Support is provided for the dsPIC33 DSCs, SAM and PIC32MK motor control MCUs - dsPIC33CK Low-voltage motor control development board: Provides a platform for application development and a reference for customer board design for the dsPIC33CK family.

- Low-cost, high-efficiency refrigerator compressor reference design: Joins a growing family of turnkey designs that showcase best practices for application-specific motor control designs that shorten the time to market.

The dsPIC33CK64MC105 DSCs are available in six packages as small as 4 x 4 mm with pin counts from 28 to 48 and priced starting at $1.13 for 10,000 units with memory ranging from 32KB to 64KB of Flash with 8KB of RAM. PIC32MK devices are available from 48 to 100 and priced starting at $3.27 for 10,000 units with memory ranging from 256KB to 1MB of Flash, and 64KB to 256KB of RAM.

For additional information, contact a Microchip sales representative, authorized worldwide distributor, or visit Microchip’s website. To purchase products mentioned here visit https://www.microchip.com/