How Electronic Test and Measurement (ETM) Manufacturers Can Prepare for and Benefit from 5G

Randy Oltman, Analog Devices, Inc

5G Is Coming

5G Is Coming

For many, that short statement is both a beacon of hope and a source of trepidation. This is especially true for test equipment manufacturers. While 5G offers the opportunity for healthy growth, there are several factors that will make reaping benefits from this generation of wireless broadband technology more challenging than it was for its predecessors.

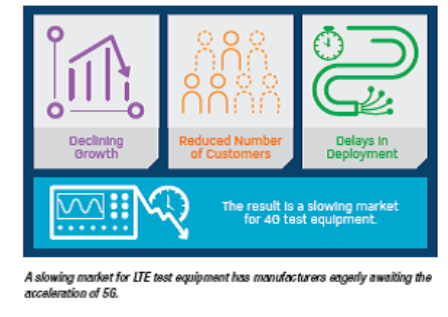

Let’s start with the current situation for electronic test and measurement (ETM) manufacturers. What generates growth in the wireless ETM business is the combination of new handset models, an increasing volume of annual handset shipments, and wireless technology advancements that drive new infrastructure equipment. We have seen a reduction in the growth rate of handset shipments, as annual shipment volumes have started to exceed 1 billion units. At the same time, mergers and acquisitions in the wireless infrastructure industry have reduced the number of customers in that segment. Finally, ETM manufacturers have also been coping with delays in the deployment of LTE-advanced carrier aggregation in major markets. The result is a slowing market for LTE R&D and production test equipment, as the industry awaits the technology shift to 5G.

5G Is Coming—with Challenges

5G Is Coming—with Challenges

As wireless broadband technology has evolved from generation to generation—and especially from feature to feature—ETM manufacturers have often been able to rely on software upgrades to adapt to changes.

The move to 5G, however, is seen as a giant stride forward that will require new and far more complex solutions.

Behind the faster speed, reduced latency, increased capacity, and improved reliability of 5G are new and less familiar technologies, such as millimetre wave, massive MIMO, and adaptive beamforming—all of which will demand significantly more advanced base stations and customer devices.

The most substantial change to the 5G physical layer is the option for millimeter wave transmission coupled with adaptive beamforming requiring a large number of antenna elements. While millimeter wave transmission is a familiar technology for point-to-point, line-of-sight wireless backhaul, using those frequencies in a cellular topology, where each cell serves hundreds or thousands of mobile users, and where many antennas will be integrated into advanced device packaging, is challenging and uncharted territory. In order to research, develop, and test the new technologies behind 5G, ETM equipment will have to deliver far more advanced capabilities than previous generations of equipment. The ETM challenge is made more difficult by the fact that the 5G standards have not yet been finalized. And, like previous generations of wireless technology, there is the very strong desire by operators to be first with deployed networks, intensifying the need for ETM equipment early in the technology lifecycle.

Normally, this list of challenges would excite and energize an R&D group. However, the slackening growth in LTE ETM equipment has left some manufacturers with far fewer resources to devote to 5G innovation and development.

A Peek Behind the Curtain

If you want to go fast, go alone. If you want to go far, go together. While 5G introduces significant hurdles, they’re not insurmountable, especially if you subscribe to the wisdom of the African proverb above. New levels of cooperation can be seen throughout the wireless industry. Instrumentation, wireless infrastructure, semiconductor, and software organizations are working together with standards bodies, research organizations, and government regulators worldwide to ensure that 5G is a unified standard addressing the many challenging performance goals, including unprecedented speed, connection density, and ubiquity. Association with important wireless industry organizations such as ITU and 3GPP, and collaboration with any of the multitude of important research organizations, such as NIST and any of the numerous 5G research alliances, is a first step toward greater understanding of the 5G technology trajectory. In addition, ETM manufacturers appear to be gaining a better foothold in the 5G market by forming partnerships and alliances with suppliers.

If you want to go fast, go alone. If you want to go far, go together. While 5G introduces significant hurdles, they’re not insurmountable, especially if you subscribe to the wisdom of the African proverb above. New levels of cooperation can be seen throughout the wireless industry. Instrumentation, wireless infrastructure, semiconductor, and software organizations are working together with standards bodies, research organizations, and government regulators worldwide to ensure that 5G is a unified standard addressing the many challenging performance goals, including unprecedented speed, connection density, and ubiquity. Association with important wireless industry organizations such as ITU and 3GPP, and collaboration with any of the multitude of important research organizations, such as NIST and any of the numerous 5G research alliances, is a first step toward greater understanding of the 5G technology trajectory. In addition, ETM manufacturers appear to be gaining a better foothold in the 5G market by forming partnerships and alliances with suppliers.

Moving supplier relationships from highly transactional to being more collaborative can bring greater effectiveness to ETM manufacturers.

Knowledge sharing and close collaboration with private companies, including operators and suppliers, is essential to timely delivery of new test products with features that are best aligned with early market needs.

Nondisclosure agreements and other proprietary arrangements are giving manufacturers early access to new ideas and emerging technologies that are further enabling the technological breakthroughs required to deliver 5G test capabilities.

Component suppliers are providing information to optimize the performance of existing products beyond published data or are going a step further, such as creating part derivatives to meet specific needs. The right partnerships can bolster an ETM organization’s strengths with early access to advanced technology. Further, by transferring design work to experienced suppliers, an ETM manufacturer can free up scarce engineering resources—allowing them to focus on their strength of delivering value-added product features.

Combined, the partnering activities outlined above are helping ETM manufacturers get the solutions they need, accelerating their own schedules, and helping them and their customers succeed.

The Challenge to Develop Ahead of Standards

With the desire to reduce time to market and meet the demands of 5G, ETM manufacturers need to develop equipment prior to standards being finalized. Because 5G standards will remain in flux for the foreseeable future, working with the right supplier is giving manufacturers access to high performance solutions across the entire signal chain, from millimetre wave to bits. In that way, even as the 5G standard changes, there will be no need to scrap the original hardware design.

Integration

ETM manufacturers will face increased demands for greater capabilities and lower costs. As a result, test products for 5G will be far more complex than those of generations before. Looking beyond individual components to chipsets and system solutions is helping manufacturers squeeze more performance out of limited space and lower cost targets—something especially demanded of modular instrumentation. At the same time, this high level of integration, as well as the increased signal chain count required for MIMO and beamforming, is putting even greater demands on power. By working with suppliers, especially those with the broadest portfolio of products, it’s becoming possible to improve engineer components into complete signal chain solutions to meet the demanding performance, power, space, and time-to-market requirements of tomorrow’s instrumentation.

Ready or Not

5G is an evolutionary leap rather than a simple generational step up. While questions still remain about what 5G will be when it arrives, there is no doubt that it’s on the way. Whether 5G becomes an opportunity for ETM manufacturers will depend heavily on whether they are ready when this new technology arrives. Embracing partnerships and alliances with key suppliers will significantly help ETM manufacturers thrive in the coming 5G market.

About the Author

Randy Oltman is systems applications manager for RF and high speed instrumentation at Analog Devices, based in ADI’s Wilmington, Massachusetts, office.

He is responsible for applications, business development, and marketing for the test and measurement industry focusing on RF and high speed applications. Randy has over 20 years of experience in the test and measurement industry, including roles in design, engineering management, and product management. Randy received a B.S. in electrical engineering from Rensselaer Polytechnic Institute and M.S. and M.B.A. degrees from Rutgers University. Randy’s patents include technology for drive test reproduction in laboratory environments and location technologies for concert environments. He can be reached at randy.oltman@analog.com.