LOWER WEIGHT, HIGHER PERFORMANCE

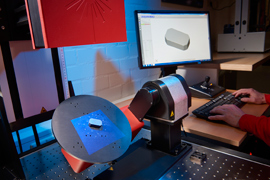

At the Airtec in Munich, the newly AS9100c certified Goudsmit Magnetics Group (stand A1-G93) will present a range of magnetic product solutions for the aerospace industry. The company designs, manufactures and supplies magnet systems and permanent magnets that are lower in weight than their predecessors and continue to perform optimally over the long term in the toughest conditions. Such magnet systems can be found in actuators, linear drives and electric motors, including those intended for the aerospace industry. Special software is also used to simulate and test whether the critical requirements for tensile forces, torques, field strength, temperature and sensor specifications are met. Weight reduction – which is always desirable for the aerospace industry – is made possible through the use of alternative magnet types with higher efficiency.

At the Airtec in Munich, the newly AS9100c certified Goudsmit Magnetics Group (stand A1-G93) will present a range of magnetic product solutions for the aerospace industry. The company designs, manufactures and supplies magnet systems and permanent magnets that are lower in weight than their predecessors and continue to perform optimally over the long term in the toughest conditions. Such magnet systems can be found in actuators, linear drives and electric motors, including those intended for the aerospace industry. Special software is also used to simulate and test whether the critical requirements for tensile forces, torques, field strength, temperature and sensor specifications are met. Weight reduction – which is always desirable for the aerospace industry – is made possible through the use of alternative magnet types with higher efficiency.

AS9100c

Having recently attained AS9100 certification, the company is now a qualified supplier to the aerospace/aviation industry. Since attaining ISO/TS 16949:2009 certification in 2008, Goudsmit has been a supplier to the automotive industry. Attaining the AS9100 certification was the next step. In addition to the aerospace and automotive industries, magnets are indispensable in the medical, greentech and oil & gas industries. The family business established in 1959 particularly distinguishes itself in the areas of magnetic measurements, quality control and product development.

MAGNET ASSEMBLIES

The company supplies the basic principles, data and knowledge for the design process of magnet assemblies. The company’s embedded knowledge of the physical and mechanical properties of magnetic materials is employed from the earliest stages of design and is also called upon to suggest effective, lighter and cost-effective alternatives. This is achieved in part through the use of analytical methods for describing magnetic circuits, calculation methods for determining the required dimensions of permanent magnet circuits and two- or three-dimensional finite elements processes. The development of a completely new product that is to be delivered fully assembled and according to specifications is also among the possibilities.