Petr Stukjunger, Senior Application Engineer, EMEA Marketing and Applications, STMicroelectronics Czech Republic

Low power applications take advantage of using MEMS accelerometer sensors for increasing battery life. Sensors are becoming less and less power hungry and embed features that help decreasing overall system power consumption. For example motion activated wake up allows to keep the entire system sleeping when user is not utilizing the device. Nevertheless there are also other possibilities how to make use of a MEMS accelerometer to decrease overall power consumption.

Low power applications take advantage of using MEMS accelerometer sensors for increasing battery life. Sensors are becoming less and less power hungry and embed features that help decreasing overall system power consumption. For example motion activated wake up allows to keep the entire system sleeping when user is not utilizing the device. Nevertheless there are also other possibilities how to make use of a MEMS accelerometer to decrease overall power consumption.

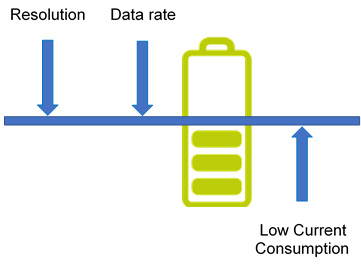

Starting from MEMS accelerometer sensor itself, it should be flexible in its operating modes. As depicted in Figure 1. there is a well-known trade-off between sensor’s resolution and its output data rate on one side and the current consumption on the other side – higher the resolution or the data rate, higher the current consumption and vice versa. Fortunately there are sensors on the market that are able to operate at few micro amps and consume couple of nano amps in power down or standby mode.

For high demanding applications operating mode of sensor can be changed on the fly, utilizing higher resolution and data rates only when it is really needed. Some sensors are even able to perform this mode switching automatically. User configures resolution and data rate needed in active state and defines a condition for enabling it. Then sensor is switched into inactive state where it still measures data, but at very low data rate and resolution waiting for the condition (a motion event) to switch back to active state.

Another good design practice is to utilize low power supply level, because lower power supply level means also lower current consumption. That’s why for low power applications 1.8V power supply is preferred.

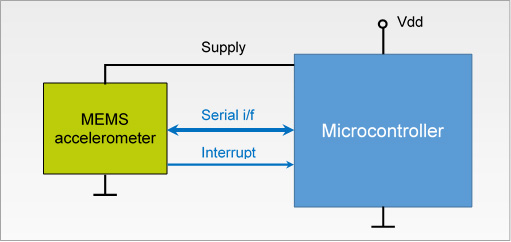

In some designs power cycling of the sensor can be used. Sensor’s power supply is activated only when motion data are supposed to be measured, otherwise the sensor is powered off. This can be even achieved by supplying the sensor from microcontroller’s pin as shown in Figure 2. When applying this technique power consumption budget needs to be calculated properly, because with every start of the sensor it is required to configure it and wait until its outputs are settled to provide correct data.

Majority of MEMS accelerometers are digital sensors, which means that they internally convert measured analogue signals to digital data. Shorter bill of materials thanks to integrated AD convertor and lower susceptibility to signal distortions are not the only advantages. Thanks to embedded interrupt generators MEMS accelerometer can generate a trigger signal when certain user-parametrized conditions are met. This is where motion activated wake up comes from. Microcontroller (MCU) configures the sensor to generate a wake up trigger and goes itself into a very low power sleep mode. When a motion is detected sensor will generate an interrupt signal, MCU receives the signal, switches into an appropriate operating mode and finally handles situation that has occurred.

Digital sensors can also take over tasks related to motion processing normally done in MCU. MCU could do the same job of course, but with much lower power efficiency – the MCU in mili amps range while the sensor in micro amps range. Detection of movements like free fall, single and double tap (user actions similar to mouse click), portrait / landscape orientation detection and others are realized by internal logic of sensor. MCU does not need to make any computations, just wait for an interrupt trigger and react to the movement only when it occurs.

Digital sensors often integrate configurable filters which are conditioning acceleration data just measured. These can be low-pass, high-pass or even anti-aliasing filters that pre-process data for the MCU and offload it even more.

Data buffer, in most cases FIFO type, embedded in sensor will lower current consumption too, because it will allow MCU to read data less frequently. This way MCU will be able do other tasks, stay longer in sleep and also save time needed for serial communication with the sensor.

Serial communication between sensor and MCU contributes to overall power consumption too. For very low power applications dealing with every micro amp, serial communication could have a significant impact. Most of MEMS accelerometers communicate over SPI or I2C interfaces. SPI interface is more efficient in terms of power consumption for three reasons: first there are no pull-ups on communication lines causing extra current consumption, second it supports higher data rates and third it has less overhead in serial protocol.

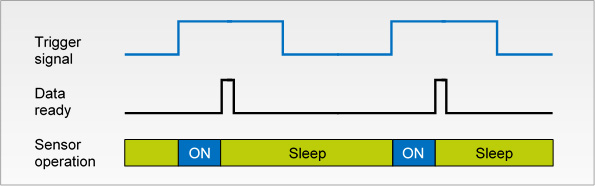

Regardless the interface, significant reduction of serial communication can be achieved if instead of polling the sensor, i. e. continuously asking for status of new data availability, the application rather utilizes data ready interrupt. Data ready interrupt is automatically generated by sensor when it has finished data measurement and conversion and new set of data is ready to be read by MCU. When this interrupt is activated, MCU can immediately read output data from sensor in one single read operation.

As said already lower sensor output data rate means lower current consumption. So called single data conversion mechanism allows to match perfectly data rate of the sensor with application needs as shown in Figure 3. Using this mechanism measurements are started either by external trigger signal routed on a sensor’s pin or by register write initiated from MCU using serial command. Data acquired this way are then stored inside the sensor. Sensor can also initiate a data ready interrupt signal informing MCU that data conversion has been completed and data is now available to be read by the application. Thanks to this feature data rates even smaller than 1Hz or basically any other rates beside the pre-defined ones are achievable.

We have discussed MEMS accelerometer sensor’s features that are important for low power applications and also ways how to utilize them in system design. STMicroelectronics’ latest ultra-low-power 3-axis MEMS accelerometer LIS2DW12 brings flexibility in designing new applications with accelerometer sensor thanks to its very low current consumption down to 1uA, number of operating modes, wide range of output data rates, rich set of embedded digital features, high temperature stability and enhanced features like digital filters and FIFO buffer. By seeing this we are convinced many low power applications will take benefits of LIS2DW12. The sensor will bring advantage for its users, in particular in the following listed areas: motion-activated functions and user interfaces, smart power saving for handheld devices, motion detection for appliances and impact recognition logging for wireless sensor nodes.