By Duane Benson

The board surface names: HAL and HASL (hot air leveling and hot air surface leveling) refer to the same thing. They are interchangeable terms. With that out of the way, I’ll get to my point, which is that HASL is not the right surface for all applications.

The board surface names: HAL and HASL (hot air leveling and hot air surface leveling) refer to the same thing. They are interchangeable terms. With that out of the way, I’ll get to my point, which is that HASL is not the right surface for all applications.

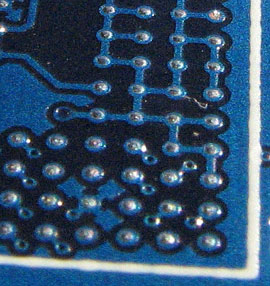

Take a look at the photo proivded. This is a 0.5 mm pitch BGA land, using lead free HASL. Don’t expect good results with this board. It’s a good quality HASL board. Even the bumps on the pads are not out of line for a HASL PC board. It’s not a defect. It’s the HASL works.

The catch is that, while the PC board is perfectly good, it’s not the correct board surface to use for all parts. HASL is fine for larger parts, but for small components, it’s archaic and not reliable.

BGAs require a flat surface (also called a planar surface). With the bumps common on HASL boards, the BGA won’t have a flat surface. The solder paste won’t adhere evenly to the pads. The BGA will probably slide off the pads before reflow. It may end up far enough off that it can’t self-center, as BGAs usually do.

The HASL pads won’t all have an even amount of solder left on the board. Some pads will have more, some less. When added to the solder paste, the pads with more solder may end up bridging.

All of the issues become even more severe as the parts get smaller. Wafer scale parts, 0.4 mm pitch parts, 0201 passives, and other similarly or smaller sized components are essentially incompatible with the HASL surface.

So, what do you do? Order your boards with immersion silver or ENIG. Both give a nice flat surface that BGAs like.

Duane Benson is the Chief Technology Champion at Screaming Circuits, a prototype PCB assembly electronic manufacturing company in Canby, Oregon.