Courtesy: Khatod Optoelectronic

In Today’s toughest LED Manufacturing process challenges, Khatod products leverage nearly three decades of hands-on experience in making lenses for SSL in a wide range of applications. Since our inception in 1985, unique on the international scene, Khatod has specified and developed the entire product process 100% in-house, Milano, Italy. A full optical service – from project to object – encompassing all the product development processes based on the latest in technology. Khatod offers full series of optical solutions for endless applications as well as a great capability in the realization of custom optics. We are able to develop the customers’ projects by collaborating with their designers or being their designers.

As a front-runner in the designing and manufacturing of Optical Solutions for the most popular HB COB and Power LEDs, Khatod was first to meet the challenge of realizing the first TIR Lens made of Silicone already a couple of years ago. The synergy between Khatod and Momentive Performance Materials, a forefront manufacturer of special materials for the industry, has led to the realization of one of the most important innovations in the lighting industry.

Today, Khatod was first to launch on the market The World’s First Range of SILICONE LENSES FOR HB & COB LEDs, a totally new design by Khatod. SIO3 SILICONE LENSES are a KHATOD PATENT.

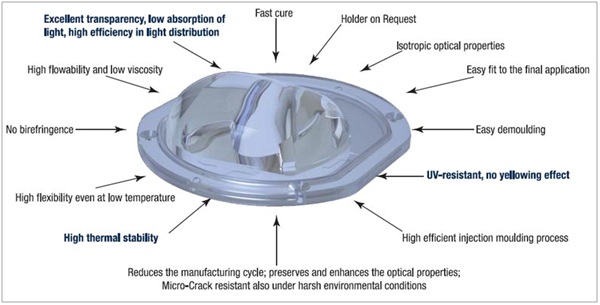

Optimized for most popular HB LEDs and COB LEDs, SIO3 SILICONE LENSES from Khatod are FREE FORM LENSES, engineered by implementing new optical techniques and manufactured by using the cold injection-moulding process, specially customized by Khatod. Designed for Street Lighting applications, are perfect for any application in Wide Area Lighting, Outdoor and Indoor.

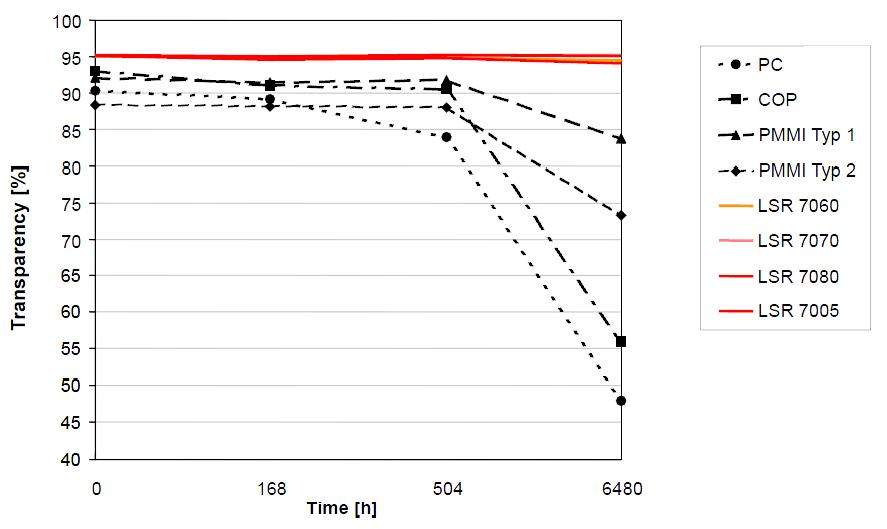

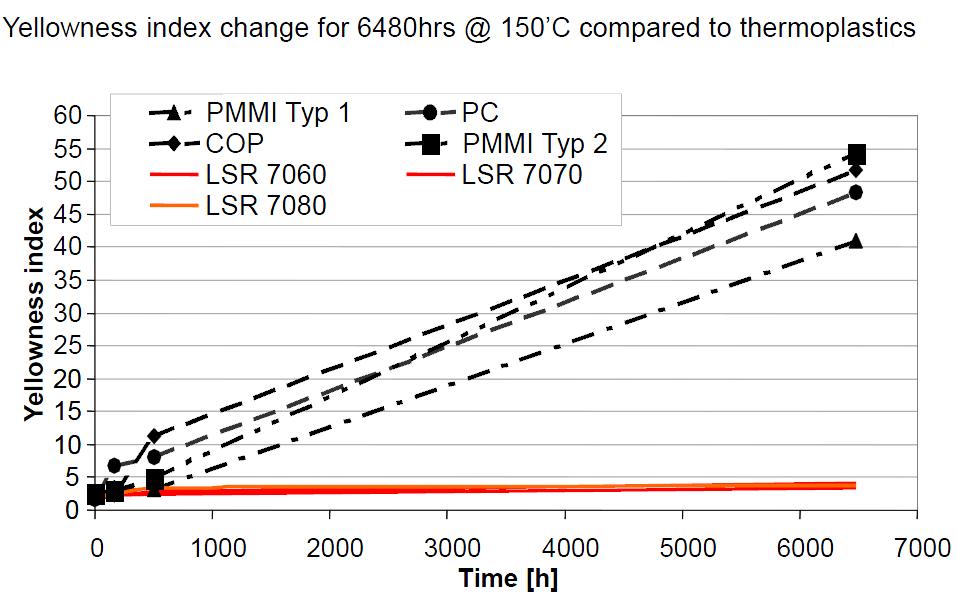

The LEDs of latest generation – High Brightness LEDs and COB LEDs – achieve very high temperatures which could put strain on the conventional polymers such as PMMI, PMMA and PC.

Thanks to the most cutting-edge engineering and the advanced technologies developed by Khatod R&D Team, the typical properties of Silicone have not only been totally transferred but even boosted in the realization process of the SIO3 Silicone Lenses from Khatod.

Silicone, as an isotropic material, provides SIO3 Lenses with high flexibility which allows an easy fit as well as a perfect compensation for the construction mechanical tolerances typical of the final application.

New optical techniques allowing to sharpen extreme angles and elaborate specific geometries have been developed in order to make this innovative lenses able to achieve a superior optical refractive index, while delivering an optical performance level perfectly complying with the optical efficiency requirements posed by the HB and COB LEDs of latest generation.

Continuous research and experimentation together with the great expertise in lensing , have led Khatod to work out a totally new transformation process in the production cycle.

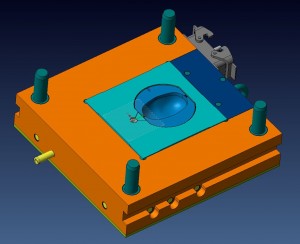

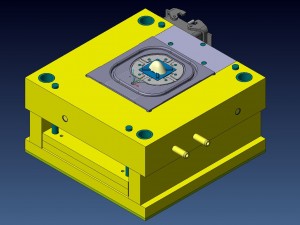

The core of the project is in the molding process. By its nature, silicone is molded cool resulting in a shorter manufacturing cycle. The optical geometry being equal, the manufacturing cycle of a lens made of silicone is considerably reduced than the one of a lens made of conventional polymers.

Cooling time takes up over 50% of cycle time and starts once the injection phase is finished : the hotter the melted plastics, the longer the cooling time, and the thicker the part produced, the longer the cooling time, resulting in some issues typical of this process.

Instead, when using Silicone, being the material in liquid form, it is injected cold, resulting in significantly reduced molding process time. However, cold injection molding process needs a specific equipment, considerably different from the traditional systems : tooling must be accurate to one hundredth of a millimeter, and the mixing process conditions must be created perfect in order to meet the typical requirements of the silicone selected.

Besides the special optical technologies developed by Khatod, also the injection system engineered and customized by Khatod plays a key role in the creation of our SIO3 optics, the world’s first range of silicone lenses for HB & COB LEDs. Such a success is not for everyone but only for those who are always at the forefront of research and development.

The newest SIO3 Silicone Lenses from Khatod not only accomplish a high optical refractive index but also deliver an optical performance level which perfectly complies with the optical efficiency requirements posed by the LEDs of latest generation.

Why choosing a lens made of SILICONE?

The LEDs of latest generation – High Brightness LEDs – achieve very high temperatures which could put strain on the conventional polymers such as PMMI, PMMA and PC.

– Silicone features high temperatures resistance, strong heat aging resistance and high chemical resistance, ultraviolet (UV) stability, purity, clarity, stable mechanical properties at a temperature range from –40°C to 200°C.

– Silicone considerably reduces the yellowing effect, so making SIO3 Lenses perfect for the outdoor applications.

– The Silicone material selected by Khatod for the manufacturing of the SIO3 lenses is a high transparency two-component liquid silicone rubber with excellent features for injection molding processes: offers a fast cure, low viscosity and high flow. These characteristics increase productivity significantly by reducing injection time and total cycle time.

– No extra protection, as for example glass in case of head-pole, and no gasket for IP insulation are needed: Specific for Street Lighting applications.

– As an isotropic material, Silicone provides SIO3 Lenses with high flexibility which allows an easy fit to the final application.

– As an elastomer, Silicone provides a perfect compensation for the construction mechanical tolerances, an excellent feature helping a perfect fitting in the final application.

Materials Transformation process: from Liquid Silicone Rubber to SIO3 Silicone Lenses

Manufacturing Process

The optical geometry being equal, the manufacturing process time of a lens made of silicone is considerably reduced than the one of a lens made of a conventional polymer (PMMA, PMMI, PC). While on the one hand the silicone reduces the manufacturing process time, resulting undoubtedly beneficial to the production costs and energy savings, on the other it requires a great technical expertise and skill in implementing this procedure.

Also, when a lens is considerably large, as in the case of SiO3 Lenses, the transformation process is much more complicated. Great care and technical mastery are needed either when the silicone is injected or when the molded part is removed from the mould in the demolding step.

Injection Molding : Thermoplastics compared to Silicone<

– When using the Thermoplastics, the material is in pellet form and needs to be melted until soft enough for the injection process. The material is injected HOT. The cooling process occurs in the mould when the injection phase is completed. The larger the part produced, the longer the cooling time.

– When using the Silicone, the material is in liquid form and is injected COLD. No cooling process needs to be implemented. This results in significantly reduced molding process time.

Cold Injection Molding : Silicone Rubber

Cold injection molding process needs specific molds and tooling, considerably different from the traditional systems :

– Tooling must be accurate to one hundredth of a millimeter.

– The injection system, customized by Khatod, is realized with innovative technologies never applied to the injection processes before.

– The elastomer used to realize the SIO3 Silicone Lenses is a two-component material which requires the mixing process conditions are adjusted perfectly in order to realize the specific characteristics of the SIO3 Lenses and achieve their typical high quality performance.

SIO3 – SILICONE LENSES FOR HB & COB LEDs .The World’s First Range. PATENTED

SIO3 – SILICONE LENSES from Khatod are optimized for most popular HB LEDs and COB LEDs.

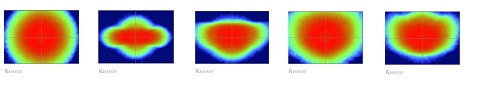

Designed for Street Light applications, comply with IESNA Standards: Type I – Type II – Type III – Type IV – Type V, Short or Medium light distribution depending on the LED used; and ME3a. Excellent in any application in Wide Area Lighting, Outdoor and Indoor. Preserve and enhance the typical characteristics of silicone.

Optic type: FREE FORM LENSES, engineered by using new optical techniques; manufactured by using the most advanced technology in cold injection-molding. Beam Angles: 1 rotosymmetrical, 3 asymmetric, 1 axially symmetrical in x, y (rectangular spot). Size: 111mm (w) x 110mm (l) x 32/35mm (h).

Optic Features: excellent transparency; high optical efficiency; no birefringence; high temperature resistant; flexibility at low temperatures; UV-resistant; no yellowing effect; easy fit to the final application; no need for extra protection such as glass or gasket for IP in case of head-pole; micro-crack resistant under harsh environmental conditions; immersion-proof; explosion-proof.

Decades dedicated to the development of new technologies, continuous research and experimentation have enabled Khatod to be one of the greatest innovators in optical solutions for LED Lighting. The creation of the exclusive range of SIO3 Lenses is just the latest result of Khatod’s mastery to blend two most important elements, essential for the realization of cutting-edge products: the capability to work out totally new manufacturing processes when new requirements are posed, and the expertise to select the most suitable and performing materials meeting such requirements.

Khatod, always one step ahead.