Challenges and solutions for the fourth wave of Industrial revolution

Modern mankind has witnessed two revolutions which have influenced its daily life in many ways; first came the Industrial revolution which gave us the Airplanes, Machines, Factories; this age transformed human’s life both culturally and economically. Then came the internet revolution and gifted us unprecedented computing power, access to information. Lives have never been the same since then.

Now we see the amalgamation of these two revolutions giving life to a new revolution called “Internet of Things“(IoT). IoT is simply a network of objects or things having a unique ID which could communicate with each other. “Things” could be anything such as Airplane turbine, the train, the TV, and just about anything.

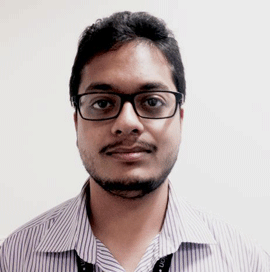

Companies spend a lot of time & money in collecting data, maintaining & diagnosing machines, for instance; consider an electricity substation which malfunctions due to excess loading, bunch of resources are squandered behind locating, diagnosing and repairing it. Now assume if the substation had the ability to report minute by minute load status to the central grid, this situation could have been avoided, if not at least solved in very less time. Industrial sector has already started its R&D investments on understanding the feasibility of adding wireless functionality into their systems. With the advances in semiconductor technology making small size, low on power consumption devices which could do wireless communication has become easy; Zig bee, Wi-Fi , 6LowPAN are the widely used wireless technologies in IoT.

Challenges of adding Wireless functionality to Industrial systems

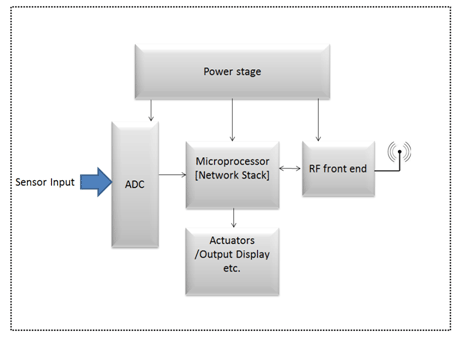

The foremost concern of adding connectivity to the industrial systems is the “System” itself, as they have a limited budget of processing power and interfaces on them. Making grounds up design with connectivity is a simpler job than modifying the existing systems to incorporate connectivity as the existing systems might not have enough processing power to process the complex wireless stacks like Wi-Fi, ZigBee. However, it is a herculean task for an Industrial company to stop their production lines for weeks and replace trusted –old equipment with new equipment and doing so will result in huge losses.

Another major concern is security of the data floating in the network; let’s take an instance of a production line which is being run from a distant Human Machine Interface, There is a great possibility that an intrusion into the network, by a hacker, could give the hacker control over the entire production line. This has always been a possibility with a computer network but it is now that our daily “Things” are being connected to the cloud (Internet of Things) the impact of this intrusion is a lot more severe.

Another instance is wherein a home automation system consisting of all the appliances: Watches, Phone, Presence Detectors and even things such as Electricity, Gas Meters, etc. are connected to form a Home Area Network (HAN).

So now a hacker, who gains access to your HAN, has all the data at his disposal. The data from smart door lock can tell him if you are in the house or not, as can the data from the smart HVAC systems. In fact which room you are in can also be traced based on the data stream of a PIR sensors in the home.

Final concern is the “Language”, a medium of communication also called the “Protocol” for the machines to exchange data. There is a myriad of protocols available today that can be used and each of these protocols has its own pros and cons. How do you select one? Will migrating to a new protocol impact the hardware design in any way? Can we get maximum nodes and maximum range? In simple sense can get best of both the worlds?

Addressing these challenges

Let’s begin with addressing these challenges, one at a time. This is where the Texas Instruments CC13xx and CC26xx family of devices come in. These are a family of software and pin compatible Wireless SoCs that integrate a low power, high performance ARM Cortex M3 microcontroller core, analog and communication peripherals, along with an ultra-low power RISC based sensor controller and a software defined radio core. The powerful M3 handles complex software stacks with ease, and this reduces the CPU load on the main controller. The on-chip AES encryption engine enables the system to achieve higher levels of security, thereby solving the information security concern.

The low power analog and sensor controller block also enable these devices to serve as a true single chip solution for wireless sensor networks.

However, what is truly unique about this family of products is the way it solves the problem of multiple prevailing protocols. The entire family is hardware and software compatible, and can support practically any low power RF protocol. The CC2650, for instance, is a multi-standard 2.4GHz wireless SoC. Its pin compatible siblings are targeted for specific applications – CC2640 for BLE, CC2630 for ZigBee/6LoWPAN, and CC2620 for RF4CE protocols respectively. The CC2650 variant is the superset part that can support all these protocols! The CC13xx family is a pin-compatible version for sub-1GHz networks.

What’s more, all these devices are supported with the same tool chain and RTOS (called TI-RTOS). Now the problem mentioned above is not as daunting as before. Migrating from BLE to ZigBee is a simple matter of changing, i.e. changing from the CC2640 to the CC2630 and compiling a different software stack. This will save the developer a lot of time while migrating from one protocol to another. Also, if the CC2650 part is chosen, then there’s literally zero hardware change required to migrate. These controllers also boast of best-in-class low power performance, with up to 10 years of operation from a single coin cell. The TIDA-00374 reference design, found on TI Designs (TI’s reference design library) illustrates the use of a CC2650 to make a low power humidity and temperature sensor node for star networks with up to 10 years of battery life from a coin cell. Since the CC2650 is used, the same hardware design can be used as-is for developing a temperature and humidity data transmitter on BLE, ZigBee, 6LoWPAN, or any other proprietary protocol running at 2.4GHz. If one wants to develop the same application for sub-1GHz, all that needs to be done is replace the CC2650 with a pin-compatible CC1310, and re-design the RF front end to match the Sub-1GHz band.

Making the switch

Despite the benefits of modern wireless networking solutions and the advancements in both semiconductor and software technology, moving from an existing, time tested, wired network to a relatively newer technology is a big step, especially for the industrial sector. An intermediate step can be executed by retrofitting existing industrial systems with wired-to-wireless protocol converters. These systems are much cheaper and faster to implement than a complete re-design of the whole system. These retro-fit solutions allow industries to migrate to newer technologies in a safer, more gradual manner, and allow them evaluate the technology before completely redesigning their system.

Complete systems re-design:

- Control over stack.

Disadvantages:

- Hardware redesign – Complex RF design , larger PCB real estate

- Expensive solution

- Software: Compatibility of the stack with the processing core.

A retrofit solution with TI’s integrated Wireless System-on-Chip Solutions:

- Economic solution

- Integrated Network processor with an additional processing core

- Lesser PCB real estate

- Stack runs on the NWP , lesser software efforts

Disadvantage:

- Lesser control over NWP stacks.

Ready designs based on suggested architecture

- Humidity & Temp Sensor Node for Star Networks Enabling 10+ Year Coin Cell Battery Life Ref Design

This design uses a nano-power system timer, SimpleLink™ ultra-low power wireless microcontroller (MCU) platform, and humidity sensing technologies to demonstrate an ultra-low power method to duty-cycle sensor end nodes.

http://www.ti.com/tool/TIDA-00374

- Isolated RS-485 to Wi-Fi Bridge with 24 VAC Power Reference Design

This design uses CC3200 Internet-on-a-chip Wireless MCU module to create a data bridge between an RS-485 network and a Wi-Fi network.

http://www.ti.com/tool/tida-00486

· Bluetooth Low Energy (Bluetooth Smart) to RS-485 Gateway

This design creates a gateway between Modbus and the Bluetooth® Smart CC2540 wireless MCU. It serves as a replacement for wires in an RS-485 network.

http://www.ti.com/tool/TIDC-BLUETOOTH-SMART-TO-RS-485-GATEWAY

Authors