Innovations for Better Tomorrow

Innovations for Better Tomorrow

ROHM Semiconductor Initiatives for the Automotive-electronics Sector

Initially developing a large number of ICs for car audio, ROHM Semiconductor has been expanding its product range as car-navigation/infotainment spread over the market. Further to it, seeing an increase in automotive electronics for Intelligent Transport Systems (ITS) include telematics and all types of communications in vehicles, between vehicles (e.g. car-to-car), and between vehicles and fixed locations (e.g. car-to-infrastructure), ROHM is accelerating the IC development for car-body electronics and Power-train ECU, and will keep releasing more new products as cars are getting more comfortable, safer and ecological.

Initially developing a large number of ICs for car audio, ROHM Semiconductor has been expanding its product range as car-navigation/infotainment spread over the market. Further to it, seeing an increase in automotive electronics for Intelligent Transport Systems (ITS) include telematics and all types of communications in vehicles, between vehicles (e.g. car-to-car), and between vehicles and fixed locations (e.g. car-to-infrastructure), ROHM is accelerating the IC development for car-body electronics and Power-train ECU, and will keep releasing more new products as cars are getting more comfortable, safer and ecological.

LED-drivers in automotive

An essential aspect of the control is the power management provided by integrated circuit (IC) LED drivers.

The usage of lighting-emitting diodes (LEDs) in automotive applications is increasing for many of the same reasons that LED lighting is penetrating non-automotive sectors. LEDs are more efficient and smaller in size, have a substantially longer life, allow considerably greater design freedom for improved esthetics, and more. In brake-lamp applications, the fast turn-on of LEDs provides an added margin of safety to warn the driver of the car behind. LEDs can respond as much as ten times faster than traditional incandescent bulbs. In addition to this safety aspect, the color of LED lighting is more natural making it safer for forward illumination. The ease of controlling LEDs also makes them a natural for intelligent-lighting systems that adjust based on vehicle sensor inputs. An essential aspect of the control is the power management provided by integrated circuit (IC) LED drivers.

Advantages of LED-drivers

Automotive applications for LEDs include interior lighting (such as dome, dash and foot-well lighting), indicator and telltale lights and infotainment LCD-backlighting, as well as exterior (signaling) functions such as tail-lights, turn-signals, brake-lights (including center high-mount stop lamps (CHMSL), parking-lights, side-marker lights, fog-lamps and daytime-running lights (DRLs). More recently, a few vehicle manufacturers have introduced LED headlamps on production models based on high-brightness (HB) LEDs. In some cases, the capabilities of an LED driver can enable more than one application to be addressed with the same LEDs.

With the low power consumption of LEDs compared to conventional lighting, an estimated 0.2 liters of fuel per 100 km and about 4 grams lower CO2 emissions per kilometer are being cited as the ultimate advantage of replacing incandescent lighting with LEDs in the DRL application alone. In electric and hybrid vehicles (EV/HEV), an 85% reduction in energy consumption from LED usage instead of incandescent bulbs translates into increased mileage range. As a result, there are several compelling reasons to implement LEDs in automotive applications.

Capabilities of LED-driver ICs

LEDs require a constant-current to produce consistent lighting. Consequently, this forms the basic operating requirements for an LED driver. The accuracy of the current source determines its customer appeal. Current fluctuations that can occur with voltage supply variations in vehicles must be avoided. Linear regulators provide a simple control and do not require electromagnetic interference (EMI) filters. However, their power dissipation can become excessive for higher power applications. Buck dc-dc converters are commonly used in vehicles as the next step up from a linear regulator. When the driver must control several LEDs in series, a boost converter topology is used. In some cases, a buck-boost topology provides the capability to address a variety of application requirements including the ability to handle voltage extremes.

LED drivers can be designed to offer a combination of series and parallel LED control. Devices with this capability built-in provide circuit designers flexibility to control LEDs in different applications with a single driver rather than requiring different devices that increase qualification testing.

Dimming the light level is a common requirement for interior lighting. However, exterior lighting has applications for brighter and normal requirements from the same LEDs. For example, brake lights/tail-lights, low-beam/daytime-running lights (DRLs) and high-beam/low-beam headlights are bi-level lighting. In some cases, lighting design may be able to address both situations with the same LEDs with the right LED driver IC.

For the harsh automotive environments, several protection circuits are required to prevent device failure under fault conditions.

Considerations in automotive design

Unlike other market segments like consumer, automotive applications have several tougher requirements that are reflected in industry standards and purchasing specifications. These unique criteria include temperature and humidity range, voltage range, ability to withstand harsh chemicals, electromagnetic interference (EMI) and electromagnetic compatibility (EMC) as well as reliability requirements dictated by qualification testing. For example, the automotive passenger compartment temperature range is -40 to 85°C.

The automotive voltage range extends from normal operation of 9 to 16V (nominally 14V) to charge the 12.6V battery under an ambient temperatures from Arizona to Alaska, and includes extreme conditions such as reverse battery (-12V), jump-start conditions of continuous double battery voltage (+24V) to fault conditions such as load-dump, which occurs when the battery is disconnected from the alternator, and other voltage transients. An unclamped load-dump can be as long as several hundred milliseconds and can easily exceed 80V, but today many manufacturers have centralized load-dump clamping circuits and subsequently require that components must withstand the transient for levels of 60 or 40V. In addition to higher voltage requirements, cranking conditions cause lower voltage that require protection for worst case situations.

High reliability in automotive applications is indicated by the need for protection circuitry such as overvoltage, under-voltage, reverse polarity, over-current, short circuit and over-temperature protection in many ICs. Also, the component’s life must be verified by testing to meet the vehicle manufacturer’s target life and warranty requirements that could be 10 years or 100,000 miles. In general, automotive IC qualification requirements are reflected in tests such as the Automotive Electronic Council’s AEC- Q100 series for integrated circuits (ICs), but individual automotive suppliers and carmakers can require tighter criteria and even further testing.

LED driver IC versus Discrete circuit to drive LEDs

A power IC process with analog, digital as well as power circuitry allows device designers to integrate the LED power switches with the control circuit – as long as the package can dissipate the power. Integrated LED switches reduce the number of components saving board space and simplifying inventory and manufacturing. As power levels increase, such as the LED drivers for HB LEDs or when the option for driving LED arrays is desired, a driver, or pre-driver, that controls external discrete output devices provide flexibility with the output switches selected based on the circuit requirements. As a result, a single LED driver can cover the requirements of several applications.

ROHM Semiconductor’s LED driver solutions for Automotive Applications

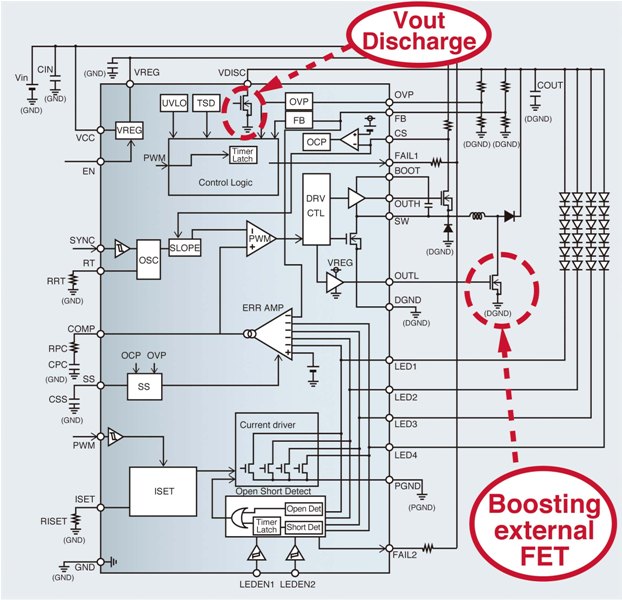

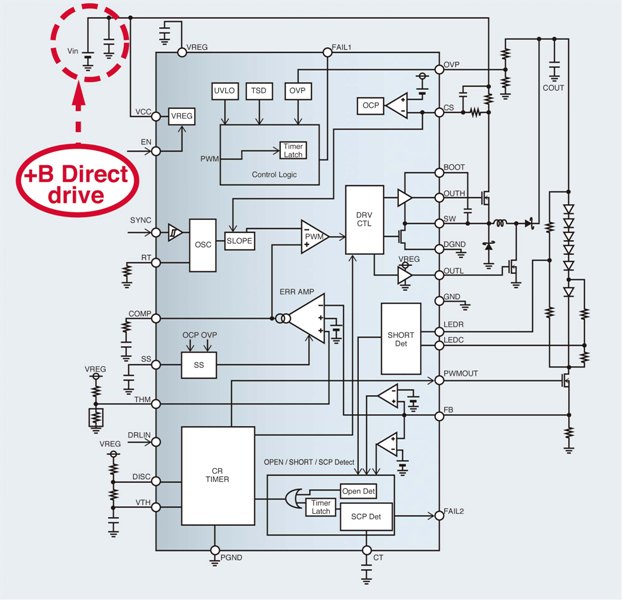

ROHM Semiconductor has highly-integrated LED driver IC solutions for passenger compartment and forward illumination applications. Driver ICs have integrated switches or in some cases, pre-drivers designed to switch external power MOSFETs. These products demonstrate the different approaches that are provided for automotive applications.

Lineup specific driver ICs dedicated to application with LEDs:

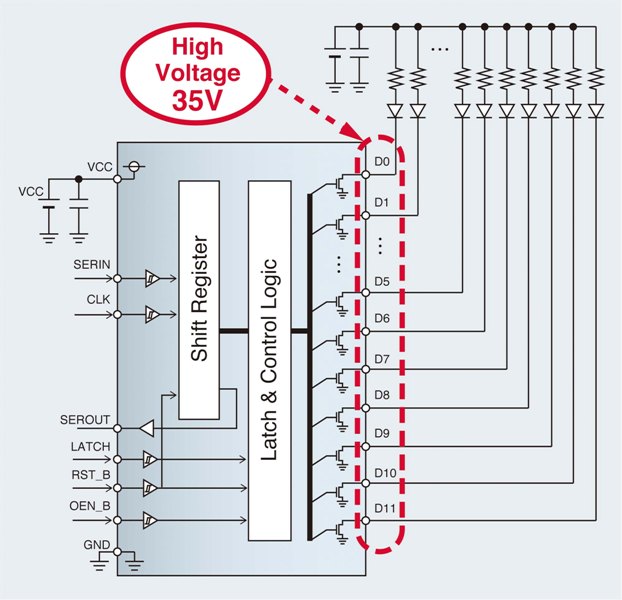

As low current consumption is more required for a car, the number of LEDs used is going up. Thus ROHM is providing a broad line-up of the specific application dedicated driver ICs from the Serial-in Parallel-out LED driver for indicators on the cluster panel or center display, the Backlight LED driver used for TFT panel and others, the LED source driver for the rear, turning, combination or other lamps, to the LED headlamp dedicated driver.

White Back light LED Drivers for LCD Panels |

|||||||

|

These high voltage LED drivers, making direct battery drive possible. In addition, an integrated boost/buck DC/DC converter ensures safe, stable operation – even during battery jitter/vibration. Multiple protection circuits, including LED open/short detection, are also built in, providing greater system reliability.

|

Automotive Headlamps/ Day-Running-Lights (DRLs) Solutions

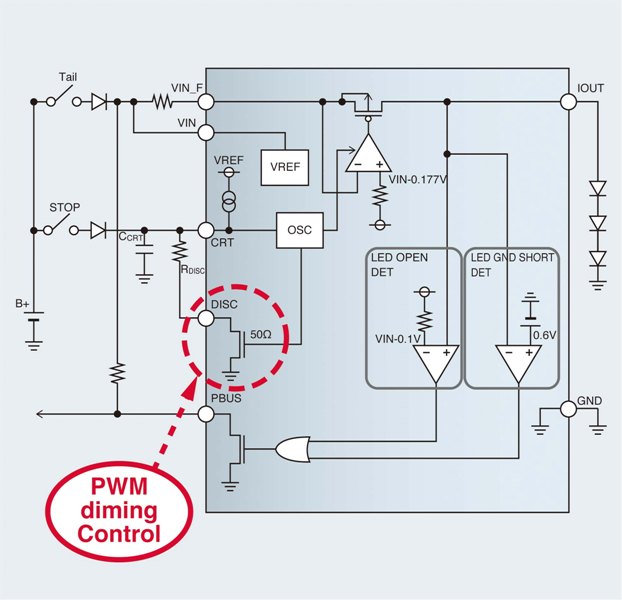

LED driver suitable for high-beam, low-beam and daytime running light circuits; controls dimming without PWM input; provides range of protection functions; unique buck/boost topology more efficient and requires fewer external components

ROHM’s BD8381EFV-M, high-brightness LED driver IC for automotive forward illumination applications. With this new flexible IC, designers can now specify the same driver for use in high-beam, low-beam and daytime running light (DRL) circuits.

The BD8381EFV-M current-mode buck/boost controller provides stable operation over a wide input voltage (5-30V) and removes constraints on the number of LEDs in series connection. Integrated protection monitors voltage, current and temperature. LED open and short circuit detection is also provided. The BD8381EFV-M has an internal PWM controller so dimming functions can be implemented with a simple external CR circuit. This same circuit can be implemented to limit output current in case of LED over-temperature detection.

ROHM said, “Instead of having to select a different drive for each headlamp function, designers can now use one device. Because of its buck/boost configuration, it can handle series LED connections numbering from just one to several.”

For more information about the expanding portfolio of automotive LED drivers in ROHM Semiconductor’s power management portfolio visit our website (www.rohm.com) or contact your local ROHM Semiconductor’sglobal sales offices.