The Industrial Summit 2024 will open in Shenzhen, China, on October 29, 2024. It will showcase over 150 demos, hold 28 sessions on motor control, power & energy, and automation, and feature our technologies and products. For those who can’t be physically there, ST will also organize more than 40 unique live streams to reach a wider audience, thus making the event more accessible. As those attendees will see, it was essential for ST to bring the Industrial Summit 2024 to more engineers and decision-makers because of its emphasis on smart energy. While climate change demands greater efficiency, data centers, renewable power sources, and new consumer trends in heating and cooling are also requiring innovative technologies.

A reference design for HVAC

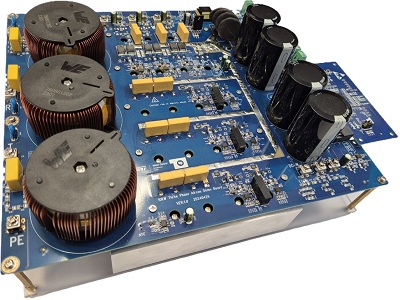

One of the most impressive demos at the Industrial Summit 2024 is a 10 kW reference design for high-power HVACs (air conditioners, heat pumps, and data centers cooling systems) with only one microcontroller driving the three-phase PFC Vienna and the BLDC motor of the compressor. Traditionally, engineers must use an MCU for each. Consequently, this more efficient system provides greater control stability and helps significantly reduce the bill of materials.

Our motor control and digital power integrated firmware library runs on an STM32G4, and despite doing so much, the CPU load hovers at about 60% only, [thanks in parts to its math coprocessors] and data management architecture capabilities. The board also features additional capabilities like KNX support and predictive maintenance applications. Put simply, we are showing a comprehensive board that would jump-start a project.

The choice to create a reference design for 10 kW applications comes from the fact that most compressors in residential and commercial HVAC solutions need around 10 kW to 15 kW. Consequently, engineers can leave the Industrial Summit 2024 with a concrete example of how they can rapidly innovate. Indeed, the point is to adapt the solution to fit specific needs. For instance, while we used 1,200 V IGBTs and silicon diodes as a default (STTH30S12 in the PFC, STGWA40M120DF3 in the compressor), designers could use ST’s SiC devices to improve efficiency and power density. Similarly, it’s relatively straightforward to adapt the current specification for a 15 kW compressor while retaining the advantage of using a single MCU.

The largest Industrial Summit 2024 demo

The automated assembly line system at the show is the first of its kind and the largest demo at the Industrial Summit 2024. Attendees get an impressive showcase of ST’s comprehensive system-level know-how featuring an unusual range of products and technologies. In total, more than 500 ST devices are present across the multitude of controllers, drivers, RFID readers, gateways, sensors, and more. It is rare to see such an expansive demo with so many different components coming from one company.

The massive demo shows a complex automation system combining three robotic arms and seven dual-motor servo drive solutions that ST designed in its competence center for a total of 14 permanent magnet linear synchronous motors that move carriages around the automation line. The seven dual servo drives communicate using EtherCAT and just one programmable logic controller (PLC), which receives real-time motion references using the CiA 402 protocol. Put simply, it’s not only an impressive demo but a turnkey solution.

The system also supports CODESYS, Profinet, Sub-1G, IO-link, and more. Moreover, this demo demonstrates our collaboration with Siemens. By leveraging their automation solutions, we can bring PLCs (Programmable Logic Controllers) and HMIs (Human Machine Interfaces) to ensure greater accuracy, reliability, and precision. Hence, our automated assembly line is one of the best examples of ST’s exhaustive portfolio and intensive expertise in embedded systems.

The demo also showcases a digital twin platform, a virtual representation of the physical manufacturing processes. The benefit of a digital twin is that its model provides unique simulation capabilities for predictive maintenance and efficiency analyses. Instead of physically monitoring every nook and cranny of the assembly line, a digital twin can help engineers anticipate issues, reduce downtimes, and test potential changes without shutting down production. The idea is already popular in the automotive and aerospace industry. By showing it at an event like the Industrial Summit 2024, ST can demystify it, thus bringing smart manufacturing to more use cases.

Rethinking AI data center power supplies

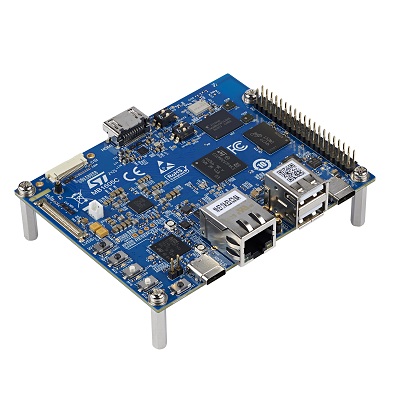

There are also new gems at the event, like a 5.5 kW power supply for AI data centers using silicon carbide for greater efficiency and improved power density. Over the past five years, cloud computing, AI, and blockchain technologies have led to the rise of data centers. It’s not only the fact that so many are cropping up worldwide but that they require a vast amount of cooling and electricity. In fact, besides running the machines themselves, cooling is the most significant power draw. Consequently, any increase in efficiency will have tremendous repercussions as the machines will use less power and need less cooling.

The power supply on display is also unique because its greater efficiency means it can do away with the bridge diode. Indeed, using SiC devices driven by STGAP as galvanic isolation gate drivers increases efficiency, enabling new topologies that further improve accessibility. The STM32G4 also brings intelligence and advanced controls to our power solutions for more intricate power distribution mechanisms that can better adapt to fluctuating loads in real time.

Put simply, building modern and feature-rich power supplies becomes more cost-effective, thus facilitating their adoption. Moreover, the supplies for AI data centers from our partners on display are just a few real-world applications with SiC devices. The demos also show that transitioning to HVDC (High-Voltage Direct Current) infrastructure also helps create greener data centers. HVDC reduces transmission losses and lowers energy consumption during power distribution, thus improving overall efficiency.

Additionally, another path to environmentally friendlier data centers relies on integrating renewable energy resources directly into the site’s operations, as it can drastically reduce the overall carbon footprint. Indeed, solar and wind, for instance, can help mitigate reliance on traditional energy grids, thus contributing to more sustainable AI data centers. Powering an AI data center with renewable energy may be challenging, which is why the Industrial Summit 2024 shows how our partners have used our devices to make it a reality. Put simply, while the world is building more data centers, ST is contributing to this new era of more energy-efficient, cost-effective, and environmentally responsible power infrastructure.

Innovating with the global leader of SiC

Because ST has more than a quarter century of experience in silicon carbide, we have been able to have a hand on the entire SiC value chain, from R&D to substrate, epitaxy, wafer fabrication, module assembly, and packaging. Unlike many competitors, we are able to innovate across the board to offer some of the best-performing devices in the industry. Moreover, being able to control all manufacturing stages, from powder to substrate, wafer, bare die, discrete devices, and power modules, also gives us a unique ability to meet the increasing demand.

As engineers wonder how to use SiC or even source it, the Industrial Summit 2024 shows how ST has answered these concerns and how it has led us to become the leading global supplier of silicon carbide. Concretely, attendees will see our broad portfolio of MOSFETs and diodes fit key automotive and industrial applications. For instance, attendees will see how our SiC MOSFETs portfolio can concretely improve efficiency, reliability, and performance in solar EV charging stations, EV on-board chargers, traction inverters, energy storage applications, and power supply for AI servers.