The Industrial Summit 2023 taking place on September 28 in Shenzhen, China, and that will be live-streamed, will have a unique emphasis on sustainability. What solutions can genuinely reduce carbon emissions? How can engineers positively lower energy consumption? What can improve our communities? Those are questions the Industrial Summit 2023 will strive to answer with solutions from our ST communities in China, Asia Pacific, and around the world. Indeed, the event is local, with plenary sessions, workshops, and hands-on seminars. However, we are also promoting more than 150 demos from ST and partners in the Asia Pacific region, thus increasing their exposure and reach. Additionally, the live stream and simultaneous translations in English will ensure greater accessibility.

ST wanted to make the Industrial Summit 2023 more impactful for an international audience by focusing on an issue pertinent worldwide: sustainability. Unfortunately, while all recognize that sustainability is essential, too many have turned it into an empty buzzword. Hence, to avoid vague promises and greenwashing initiatives, let’s hold ourselves accountable. ST is ensuring that all products on the show floor will either be already available or arrive in a few months. Consequently, all demos at the event reflect applications that are within reach. To give a preview of what will be shown, let’s explore concrete solutions for the home and the workplace.

In our neighborhood

Microgrids

The Industrial Summit 2023 recognizes that sustainability must happen not only in factories or commercial building complexes but at home, too. Hence, our microgrid demo takes devices that would traditionally service industrial environments and uses them in a domestic setting. As consumers have greater access to renewable energies, like solar or wind, and are driving more electric cars, there’s a critical need to manage resources better. Unfortunately, a massive power plant far away and serving a metropolis can’t possibly answer this new challenge. Hence, governments worldwide are looking at microgrids, small power structures capable of delivering alternative or direct current to a neighborhood or a campus.

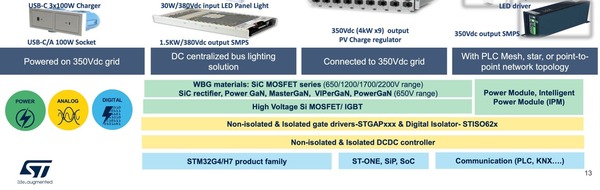

The demo shows that building such a microgrid is feasible with existing ST devices and solutions from our partners. For instance, MASTERGAN, or silicon carbide power devices, are already in 1.5 kW power supplies for sizable outdoor lighting solutions or photovoltaic regulators that transform solar energy into an electrical current that feeds a 350 V DC grid. We also have microcontrollers like the STM32G4 or STM32H7 capable of running programmable logic controllers or network solutions. Interestingly, the demo shows how complex microgrids are and how they are also within reach. In fact, cities are already adopting them, like Suzhou in China, making our presentation even more pertinent for attendees looking to work on sustainable technologies.

At Home

Washing Machine

Industrial Summit 2023 is unique because it shows how industrial solutions are also entering the home to bring energy savings to consumers. For instance, the show will feature an updated version of the washing machine demo introduced a few months ago. Last May, the onus was on its machine learning capabilities. Thanks to NanoEdge AI, it was possible to create a neural network capable of automatically figuring out the load’s weight without any extra sensors and adjusting the machine’s water and energy consumption accordingly. Today, the demo focuses on ST’s HSO (High Sensitivity Observer) sensorless motor control algorithms since it will be available for use on the STM32G4 within the ST Motor Control SDK.

In a nutshell, HSO runs on the same applicative layer as the NanoEdge AI algorithm to ensure developers can significantly optimize the power consumption of a sensorless motor by. Without adding more memory or making the overall design more complex, engineers can achieve full torque at zero speed and improve the overall energy efficiency. Practically, moving to HSO enables the washing machine to save between 5% and 40% of energy depending on the load, compared to previous state observer algorithms available in our motor control SDK. Moreover, to make the technology even more accessible, we are committing to release an STM32G4 development board running the HSO algorithm out of the box.

On the Way to Work

A KNX charging infrastructure

As people leave their homes for work, an increasing number of them take an electric vehicle. Interestingly, a recent JD Power study shows that consumers are satisfied with the charging process. While ST will always strive to improve the energy efficiency of chargers with its silicon carbide power devices, the technology has reached a performance level that satisfies most users. Consumers don’t have to wait too long or spend too much electricity charging their cars. However, the study also points out that limited public charger infrastructure and operability remain problematic. Put simply, while people like the charger they have at home, they are still unsatisfied with those in their city.

To remedy this challenge, ST is using the Industrial Summit 2023 to show an EV charging network run by KNX instead of the traditional RS485. For one, KNX offers more flexibility regarding connectors and protocols, making it far more interoperable. The industrial roots of this international standard also mean that it works great in high-power environments. For example, KNX modulation can operate with voltages of up to 7 V, whereas RS485 can only tolerate variations in the millivolt and is vastly less resistant to static electricity. Put simply, we are showing how KNX can help create the public ecosystem of charging stations people are asking

for.

We are also doing more than just showing a demo but actively working with partners collaborating with governments in the region to deploy charging stations. For instance, some have already committed to installing tens of thousands of EV charging points by 2030 and electrifying half of their public buses and taxi fleets. To put this in perspective, our KNX application can, among other things, manage 65,000 nodes. By working with the companies leading various governmental projects, we ensure that demos, like the KNX energy management system we are showing at these Industrial Summit 2023, make a real impact. And to lower the barrier to entry even further, we are promoting new reference designs for system integrators.

At Work

Servo Drives Orchestra

To make our portfolio of motor control solutions more approachable, we are showcasing our most comprehensive motor control demo. The “Servo Drives Orchestra” comprises reference designs with loads ranging from 500 W to 22 kW. Each board uses an STM32 microcontroller (an STM32G4, an STM32H7, or an STSPIN32G4), STGAP galvanic isolated drivers, ISOSD sigma-delta modulator, ST power solutions and high-performance analog devices. Additionally, the demo features the STEVAL-PROTEUS1 to add sensors like time-of-flight. There’s also a Zigbee coordinator and a Wi-Fi controller using an STM32U575 that sends data to Baidu, which then informs the UI to reflect how the systems save power, or provide features like condition monitoring based on NanoEdge AI.

Each platform controls a rope that moves a ball up and down. Attached to the ball is an LED bar that turns on or off based on its height, which is detected by a time-of-flight sensor. Everything is interconnected to an HMI system using IO-Link, so all motors move in unison, thus conveying the feeling of a machine conducting an orchestra made of motor control systems.The ensemble also demonstrates the precision of each platform that can rapidly and minutely control the position of each rope. Attending get a visual representation of what’s happening behind the scenes to help them grasp what they are seeing.

According to the 2022 World Energy Outlook report from the International Energy Agency, a key milestone for its Net Zero Emission objective by 2050requires that all industrial electric motors sold by 2035 be “best in class”, meaning that they feature vastly improved energy efficiency. Hence, a demo showcasing power-efficient motor control solutions is paramount when improving sustainability worldwide. Additionally, the Orchestra is also a material design demo because it puts our PowerGAN devices and silicon carbide MOSFETs right next to each other. Consequently, attendees get an object lesson on when and how to use these new wide bandgap transistors.

IO-Link at the system level

Our assembly line showcase is another demo that would be right at home in a factory. In this instance, machines will package 1,000 phone holders, then print and label boxes before another robot arm picks up the package to give it to attendees. The demo is significant because it features systems in use by our partners in real-world manufacturing plants. It is also a demonstration of a comprehensive ST portfolio in action. From microcontrollers to sensors, drivers, network controllers, or power devices, to name a few, attendees can see how they all work together to improve the environmental impacts of existing factories.

The other point the demo is making is that IO-Linkcan serve as a driver for improving operations. Indeed, in this demo, the HMI, programmable logic controller, IO-Link master system, motor control systems, digital inputs, air valve drivers, digital outputs, the time-of-flight sensor for presence detection, and the RFID controller are all interconnected using IO-Link. The idea is not new, and we had a massive IO-Link demo last year. However, as ST believes that the technology can significantly help optimize manufacturing operations and lead to greater sustainability, we are changing our operations to work more closely with system makers.

Traditionally, a semiconductor maker only deals with function block makers that then sell their design to system makers. However, we are enlarging the scope of our Industrial Summit 2023 by bridging the gap between function blocks and system integrators to accelerate IO-Link deployments. It would help factories update their infrastructures quicker, in the hope that we not only create more sustainable solutions but that these solutions become a reality faster. The world can’t wait for more efficient manufacturing, and neither can we.