For more than 130 years, companies around the world have depended on Intertek to ensure the quality and safety of their products, processes and systems. Intertek proudly celebrates 20 years of delivering quality solutions in India. In India Intertek have their operations all over India spread across various verticals such as commodities, minerals, consumer goods, pharmaceuticals, chemicals etc.

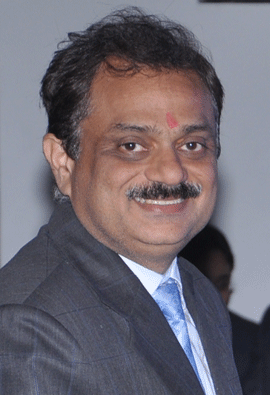

Intertek has various testing and certification facilities for testing electricals, electronics, batteries and LEDs. Here Mr. Sandeep Vig, Director, Electrical and Wireless, Intertek India speaks about Intertek offerings and standard issues in India.

-

Tell us about Intertek’s presence in India.

Intertek is a leading quality solutions provider to industries worldwide. We started our operations over 130 years ago in USA. From starting out as a marine surveying business, the company steadily entered newer areas such as minerals and materials testing. Quality Service means anything to do with the quality of the product and the supply chain which allows manufacturers to access the markets in the world and to reduce risks. We provide internationally recognized quality testing and certifications, high quality analytical, technical verification, inspection, auditing, training and consulting services to virtually every industry across the globe from textiles, toys, electronics, heating, pharmaceuticals, leather, footwear, accessories etc. Today, we have a network of more than 1,000 laboratories and offices and over 40,000 people in more than 100 countries. We are more than 20 years old in India have about 20 labs situated in India.

Specifically for the electrical market, we have four labs in Delhi, Mumbai and Bangalore. For HVAC sector we have a lab in Delhi which had been setup for partnering Bureau of Energy Efficiency (BEE) around 2004.Without a lab there can be no certification programme. So in any sector if you want to say ‘Make in India’ you will have to underpin that to quality. India’s manufactured product has to compete with products made in developed nations. So if you have to compete on the bases of quality, quality needs to be seen as an investment and not as expenditure. We can see innovations in this segment with Government’s intervention.

In HVAC& R industry energy efficiency is becoming even more relevant today and the government has also initiated the projects like smart city and smart homes. To have a better perspective, the Smart city is a collection of smart components. Smart in the sense that works efficiently, uses less energy, is green in nature and does not harm the environment. Now if you talk about Make in India, the government has to set up mandates for quality, and advocate the International/Indian Quality Standards to ensure quality manufacturing in the country

-

What has Intertek to offer in electricals and electronic testing domain? What would be the focus for the quarter in terms of expansion and business development?

Serving the electrical and electronic industry for more than 115 years Intertek offers wide range of services in electrical and electronic testing; Photobiological test with standard IEC/ EN 62471 which is applicable for LEDs allows manufacturers to evaluate safety of lamps, including luminaries; Ingrens protection (IP) test- which validates that the products enclosure will withstand moisture and dust.

To add to our portfolio, another important standard for LEDs is the ZhagaInterface specifications, which aims to standardize LED light engines and connected components. It also provides Accelerated Stress Testing (AST), which helps to achieve high product reliability and accurately stimulate real-world conditions.

Our vision over the next four years is to significantly grow our business. We will deploy both organic and inorganic routes to increase our scale in this market and our market process. We would also invest in our existing LED and batteries testing labs. We need to understand market opportunity in the overall set up and deploy our resources. The idea is to invest heavily in India, be it in terms of capability building or in terms of capability buying and gain market position by the turn of the decade. We hope that over the next few years we will be market leaders in quality services and will be able to deliver best at our end.

-

According to you, what is the scenario for acceptance of International quality standards in India and visible challenges in electrical and electronics industry?

The market is observing a continuous shift both vertically and horizontally.

While the market has accepted the need for quality standards, there still lies huge scope for growth. The companies need to invest towards quality check of the products in order to ensure their sustainability in international markets. Similarly, India has vast and extreme climatic conditions and thus it becomes even more important that the products in India have to be tested on Indian soil.

-

Please comment on future for the power equipment, electrical testing, inspection and certification business in India. Government view in terms of regulation, performance, safety and quality in this sector

Power is one of the most significant contributors to the economic growth and welfare of nation. The existence and development of adequate infrastructure is essential for sustained growth of the Indian economy. India’s power sector is undergoing a significant change that has redefined the industry outlook. Sustained economic growth continues to drive electricity demand in India. The Government of India’s focus on attaining ‘Power For All’ has accelerated capacity addition in the country.

India’s power sector needs several policy interventions and a holistic approach to solve the current power crisis within the country. Access to reliable & high quality fuel, especially coal, will present one of the biggest challenges to the sector. For example, as per the current trajectory, India may face shortage of up to 250 MT of domestic coal per annum by 2014-15. Similarly, the downstream distribution infrastructure, characterized by high AT&C losses and inefficient grid quality is another area of concern. All these issues require immediate intervention from the government through fast tracked reforms & execution. There are hiccups in the regulatory regime that are major roadblocks for the market to expand.

We have various economic challenges in power sector activity in India such as coal availability, plant equipment, transmission and distribution losses due to aged infrastructure, approval and licenses, metering accuracy etc. Also skilled manpower for construction plants, environmental clearance, contractual disputes, and inter-state issues are also roadblocks leading to demand supply gap. These all are widely discussed and also getting addressed by government.

-

Please throw some light on the regulation framework in India. How the private sector labs run performance testing, safety testing, energy efficiency certification programs across various sectors to be able to build a certain benchmark in terms of quality, performance and safety which will be a great thing over all for the market.

To curb the bootleg market for sub-standard electronics and electrical products, the government has made it compulsory for all manufacturers in India to get a Standard complaint certificate from Bureau of Indian Standards (BIS). This would ensure the safety and value for money to the customers. We are able to improve power generation-related operations, profitability, safety and performance while minimizing business risk by providing expert testing, certification and inspection related to this field that are all available on a global basis. We have the team of experts at every step involved in testing and certification life cycle. This ensures the fast and accurate delivery of the services.

- Can you tell about the specifics of Intertek’s newly commissioned electricals and electronics testing lab? Also, highlight the dynamics of LED and battery testing with growth expected in the domain.

Intertek’s newly commissioned electrical and electronics lab offers fast, expert and efficient product testing, inspection and certification solutions through our extensive global network of accredited laboratories. Intertek’s expertise in Electronics and Electrical sector covers domestic appliances, consumer and homely electronics, automotive components, heating ventilation and air conditioning equipment, monitors, telephone equipment, power supplies for IT applications, industrial controllers, general purpose luminaries, lighting, semi-conductor manufacturing, TV receivers, pumps and lab equipment, etc.

The LED lighting projects being undertaken in India are becoming popular with every passing day, which will open up huge business opportunities for the LED and battery testing sector. The LED and batteries industry today is growing at a rapid rate. According to the report, India LED Lighting Market (2014-2019) by Research and Markets, ‘India’s LED market is forecasted to reach $1,457.8 million by 2019, at a CAGR of 35.9%, during 2014-19. Government initiatives to replace incandescent bulbs with LED bulbs, increasing energy demand supply gap, declining prices are the factors driving the growth of LED lighting in India. Street lighting application accounts for majority of the market revenues in Indian LED lighting market.’