The power semiconductor market is seeing rapid growth due to the smart grid, energy storage systems (ESSs), and electric cars.

The power semiconductor market is seeing rapid growth due to the smart grid, energy storage systems (ESSs), and electric cars.

The “less power” theme was reflected in many of the technical and industry sessions. Wide band gap devices (semiconductors using materials such as silicon carbide and gallium nitride) can enable higher performance and less power for applications such as RF, LED lighting, motor drives and electrical power conversion. Energy harvesting captures minute amounts of naturally-occurring energy for many sensing, monitoring and control applications. Smart power grids will help deliver power more efficiently and reliably. Motor drivers and controllers are increasing the power efficiency of motors.

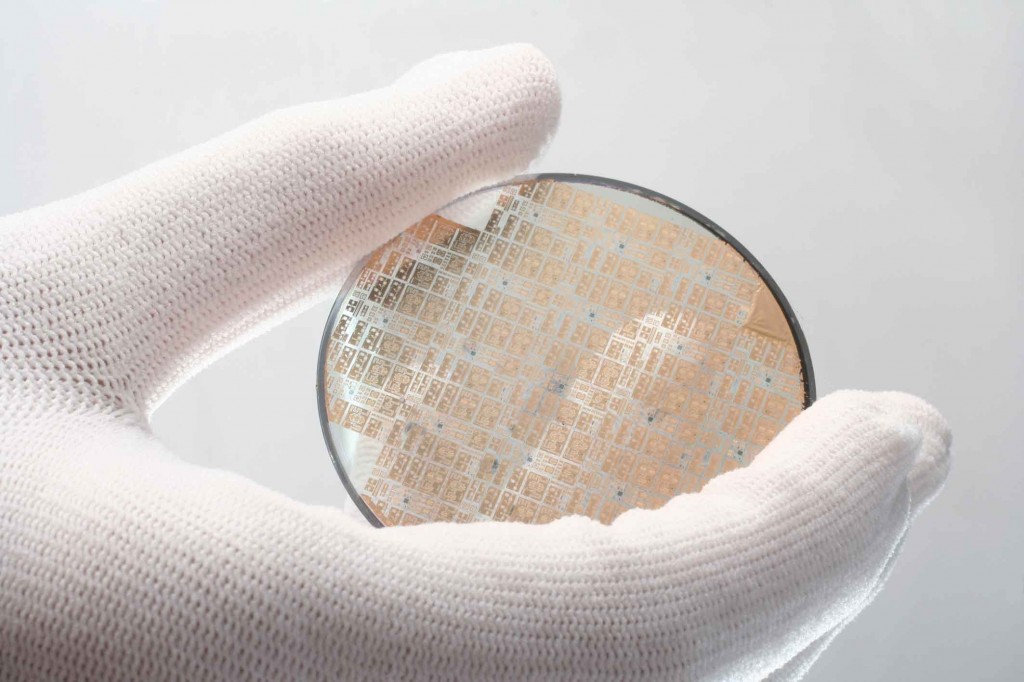

A power semiconductor is a kind of analog system semiconductor, and is used to control electric power or improve electricity consumption efficiency. The rapid growth of the power semiconductor market in recent years has been driven by the proliferation of computer and consumer electronics, such as desktop computers, notebooks, netbooks, smartphones, flat panel displays and portable media players that require sophisticated power management to improve power efficiency and extend battery life.

Key vendors dominating this space are Fairchild Semiconductor International Inc., Infineon Technologies AG, Mitsubishi Electric Corp, STMicroelectronics N.V., and Toshiba Corp.

Power semiconductors will be the largest and fastest-growing chip segment. In particular, IGBT modules (IPMs – Intelligent Power Modules) and insulated-gate bipolar transistor (IGBT) discretes will be in high demand, due to the increasing use of inverter-based variable-speed motor control technology. The inverter-based technology increases energy efficiency by controlling the speed of the motor and also helps in reducing noise levels during an appliance’s operation.

SiC & GaN Power Semiconductors Leads Power Discrete Market by 2018 Says New Research Report

SiC power semiconductors comprise SiC MOSFET, SiC JFET, SiC BJT, and SiC Schottky diodes. Currently, SiC is widely used in the development of power semiconductors; however, GaN is a wide bandgap material that offers similar performance benefits to SiC but has greater cost-reduction potential, and the market for GaN power semiconductors is expected to grow rapidly in the coming years. In addition, GaN can be made available using existing silicon substrates, which can enable mass production and reduced cost. Power semiconductors using next-generation materials such as SiC and GaN are characterized to have lower energy loss, high-speed switching, and higher heat resistance than conventionally-used silicon. The adoption of SiC and GaN power semiconductors is expected to witness a significant increase, particularly in the EV/HEV and Industrial Motor Drive segments.

“Innovation of packaging materials to enable higher operating temperatures; further development of wide bandgap technologies”

Corey Deyalsingh, Director of Power Control in the Semiconductor Business Unit, Littelfuse

Power semiconductors are consistently growing at a faster rate than all semiconductors and the general market overall; double digits annually in certain sectors. Globalization and expanding industrialization; increased factory and commercial automation demand for higher efficiency of energy conversion.

Designers of applications and systems using power semiconductor are constantly pushing for reliable operation at higher temperatures and with fewer cooling requirements. Most silicon solutions have already reached or are rapidly reaching material limitations. Wide bandgap materials such as silicon carbide and gallium nitride that can theoretically handle much higher operating temperatures, although not new materials, are receiving new attention due to recent developments of power devices. The market is beginning to explore these new technologies although they are not yet mature enough for broad adoption.

Very much related to trends, driving higher safe operating limits with silicon based devices; continued development, availability, reliability, and cost of new wide bandgap technologies; the market will most likely continue to deal with periodic supply constraints as sometimes demand gets ahead of installed capacity and manufacturers are reluctant to place expensive bets in advance of predictable demand.

From the acquisition of Teccor Electronics in 2003, a well known leader in thyristor technology, Littelfuse offers a broad portfolio of power devices up to 1000V suitable for a wide variety of applications from consumer (appliances) to industrial (factory automation, power conversion). Our product design philosophy has historically and continues to be centered around leadership in robust and reliable design; refusal to cut corners for the sake of cost or gimmicky features. Our customers expect the highest level of design support and service, and we consistently strive to deliver in this area with experienced Applications Engineers and a fully kitted lab for testing at the device and applications level.

We are excited to add some important technologies to our portfolio later this year including high voltage thyristors which will enable us to further penetrate the industrial space. Stay tuned!

“At TI we are evaluating new semiconductor material technologies to achieve higher power densities, voltages and efficiency levels that will be needed in the future.”

Srivatsa Raghunath, Technical Lead in Analog Systems, Texas Instruments India

According to IHS Inc, the power semiconductor market revenue in 2012 for power semiconductor discrete and modules fell to slightly less than $15 billion. However, the market is looking ahead and expects that by 2022 the global power semiconductor will reach approximately $65 million.

Power semiconductors have an integral function in all electronics, as they help convert electrical energy or when the energy needs to be regulated. This basic function makes it applicable in a range of verticals including automotive, industrial, consumer electronics, lighting and more. Therefore the market opportunity for power semiconductors discrete and modules will continue to grow. Additionally, the increasing demand for energy efficient products will also support the market prospects in the coming years.

One of the key drivers of power semiconductor is for power management in electronics. The growing requirement for energy efficient products has made power management ICs an important component on the board.

At TI we are evaluating new semiconductor material technologies to achieve higher power densities, voltages and efficiency levels that will be needed in the future. The reduction in the cost of silicon based power and control devices and the improvement in their performance has become the latest trend in power electronics.

Furthermore, at TI we are transforming power through energy management innovation in areas such as energy generation, conversion, distribution and control of energy demand and resources. We have a dedicated energy lab which is the focal point for intelligent energy conversion and management systems for accessible and cost-effective power delivery.

We find challenges are in efficient energy management along with necessary system protection. Though many energy management features are built into the semiconductors, the system protection features call for additional circuitry. Product compliance with respect to EMI / EMC also add complexity to the overall system design.

More integration of system protection features into the power management device and improvement in process technologies, enable robust solutions

TI’s power management integrated circuits range from standard ICs to integrated solutions, including power modules, digital power, battery management and high-performance MOSFETs and gate drivers. TI’s extensive product selection ranges from isolated AC/DC and DC/DC power supply controllers and non-isolated voltage regulators, such as switching DC/DC converters and linear regulators, to PMIC and LED drivers and display solutions. Leveraging TI’s extensive portfolio of power management products, design tools and support resources can help you build innovative, efficient and affordable solutions, getting you to market faster.

Solar IC product portfolio from TI includes solutions that help lower the cost of Photovoltaic (PV) arrays by integrating the electronics that process power for distribution, condition signals for communication, increase safety of solar arrays, and help maintain maximum power from individual panels. PV systems have historically been designed with limited electronics, mostly concentrated in the centralized DC/AC inverter. Solar IC solutions are available for various PV components including DC/DC power optimizers, DC/AC micro inverters and inverters, MPPT based battery charge controllers, and PV safety solutions including reference designs