HARTING Technology Group has been working with system integrators and IT specialists within the MICA network user organization since 2016 to enable customers to achieve data-efficient device efficiency improvements. The network presented the machine data collection and ERP application solutions based on the MICA® edge computing system at this year’s HARTING booth at Hannover Messe (Hall 11 / Booth C15). The “last mile” represented by access to process data from the shop floor is often the biggest obstacle to the Industry 4.0 concept. Network partners can contribute their respective solution expertise through collaborative projects.

HARTING Technology Group has been working with system integrators and IT specialists within the MICA network user organization since 2016 to enable customers to achieve data-efficient device efficiency improvements. The network presented the machine data collection and ERP application solutions based on the MICA® edge computing system at this year’s HARTING booth at Hannover Messe (Hall 11 / Booth C15). The “last mile” represented by access to process data from the shop floor is often the biggest obstacle to the Industry 4.0 concept. Network partners can contribute their respective solution expertise through collaborative projects.

Assystem uses demonstration devices to demonstrate how data science and machine learning can be used to identify new connections and optimize operational processes, thereby reducing production costs. The machines communicate with each other to access internal and external data. In the process, Assystem was able to demonstrate its extensive experience in OPC / UA and M2M communications. The Assystem solution is a flexible system that operates independently of the manufacturer’s automation technology and can be adapted to existing equipment.

Machine data for transparent value creation chains

SDI Innovation introduces the new Bluebox.SDI software tool for monitoring and visualizing and visualizing the actual and target conditions of production equipment such as CNC machining tools, injection moulding machines, and production lines. The tool comes with pre-set applications such as TPM, OEE calculations and trend analysis. When installed on MICA®, Bluebox.SDI can be quickly and easily deployed to production systems in a decentred mode. The control panel with display, input and selection options also makes this solution ideal for mounting on a mounting board.

SDI Innovation introduces the new Bluebox.SDI software tool for monitoring and visualizing and visualizing the actual and target conditions of production equipment such as CNC machining tools, injection moulding machines, and production lines. The tool comes with pre-set applications such as TPM, OEE calculations and trend analysis. When installed on MICA®, Bluebox.SDI can be quickly and easily deployed to production systems in a decentred mode. The control panel with display, input and selection options also makes this solution ideal for mounting on a mounting board.

SIEVERS GROUP also demonstrated HANNOVER MESSE, an Internet of Things solution developed with HARTING. Users can use it to correlate machine data with other information throughout the production process. MICA® collects operational data from various machines and equipment. SIEVERS GROUP integrates it with ERP and business intelligence applications.

Process digital and analogue sensor data in real time

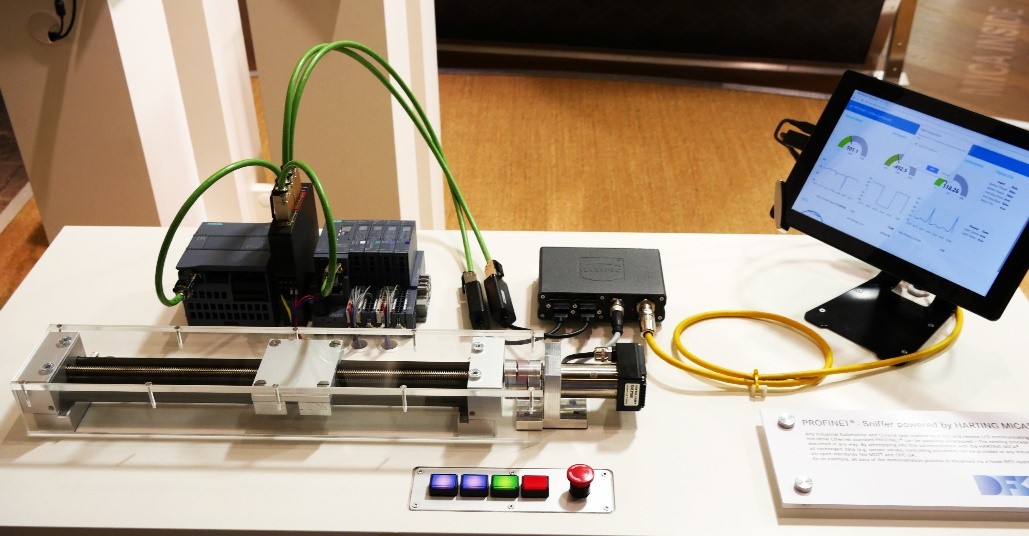

HARTING collaborated with the German Institute of Artificial Intelligence (DFKI) to demonstrate how machine data can be accurately recorded using the MICA®-based PROFINET sniffer. Any automated industrial system using SPS and the Industrial Ethernet standard PROFINET can be used for passive “sniffing”. Existing processes are completely undisturbed. By “sniffing” communication with MICA®, all exchanged data (such as sensor and actuator values) can be provided to Industrial 4.0 applications through open standards such as MQTT and OPC Ua.

As an authorized distributor for Harting, Heilind Asia provides Harting products and also value added services. Heilind Asia supports both original equipment and contract manufacturers in all market segments of the electronics industry, stocking products from the industry’s leading manufacturers in 25 component categories, with a particular focus on interconnect, electromechanical, fastener/hardware and sensor products.