MQ6 Gas sensor is used as LPG, Butane and Propane Sensor to generate alarm when there is leakage of these gases from the source. MQ6 is a highly sensitive gas sensor to petroleum based gases but less sensitive to Alcohol and Carbon di oxide. This simple sensor can be installed in the kitchen to give warning alarm if there is leakage of LPG.

MQ6 Gas sensor is used as LPG, Butane and Propane Sensor to generate alarm when there is leakage of these gases from the source. MQ6 is a highly sensitive gas sensor to petroleum based gases but less sensitive to Alcohol and Carbon di oxide. This simple sensor can be installed in the kitchen to give warning alarm if there is leakage of LPG.

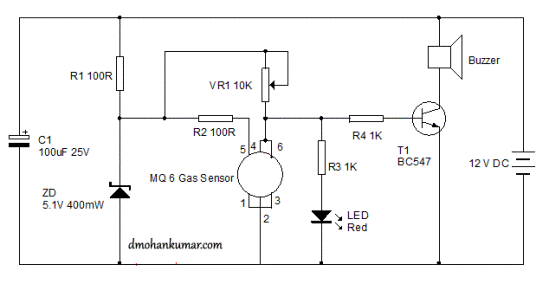

MQ6 gas sensor is a 6 pin device and it requires 5 volt DC maximum which is derived from a Zener based power supply. There is a heating element inside the sensor which becomes hot at 5 volt and remains stand by. When the sensor detects gas molecules between 100 ppm to 1000 ppm, in the atmosphere, its output turns high and triggers T1 to activate the buzzer. Red LED indicates the high output from the sensor.

Fix the unit 1-2 meters away from the burner or gas cylinder. Adjust VR1 for maximum sensitivity of gas. Place the sensor near the burner and just open the burner for few seconds and close without igniting. Adjust VR1 immediately to set the sensitivity.

Gas sensor is the device used for detecting the presence of Gases like Carbon monoxide, LPG, Ethanol, Toluene, Hydrogen etc. These are used as safety measures in work places and Home to avoid hazardous situations. The sensor can be used to generate an alarm or to activate a system to shut down the gas flow. Gas detectors are usually battery operated devices and if the gas level exceeds the pre-set level, it sends output signal to activate the circuit. Most commonly used gas sensors are LPG sensor, Smoke sensor and Alcohol sensor used in Breath analyser.

Portable gas detectors are used to monitor rooms and the surroundings of human beings, Breath etc. while fixed types are used for detecting one or more types of gases in factories, plants, hospitals etc.

Portable gas detectors are used to monitor rooms and the surroundings of human beings, Breath etc. while fixed types are used for detecting one or more types of gases in factories, plants, hospitals etc.

Portable gas detectors are used to monitor rooms and the surroundings of human beings, Breath etc. while fixed types are used for detecting one or more types of gases in factories, plants, hospitals etc.

How it works?

The Gas sensor has a sensing element, a base and a cap. The sensing element has a sensing material (Usually a Semiconductor) and a heater to heat up the sensing material. The different sensing materials used are Tin Oxide, Tungsten oxide etc. depending on the type of gas to be sensed. In principle, when the Tin Oxide is heated to high temperature, it adsorbs oxygen on its surface with a negative charge. Then the donor electrons from the Tin oxide crystals passes into the adsorbed oxygen leaving the positive charge in a space charge layer. This creates a surface potential which prevents electron flow. Inside the sensor, the current flows through the boundary of Tin oxide crystals. In the boundary of the crystals, the adsorbed oxygen forms a barrier to prevent the free movement of carriers. This potential barrier gives the electrical resistance to the sensor.

So in the standby mode the electrical resistance of the sensor is high. In the presence of a De-Oxidizing gas, the surface density of the adsorbed negatively charged oxygen decreases leading to a reduction in the size of the barrier. This reduced barrier decreases the electrical resistance of the Sensor.

Advantages

- A novel room temperature, low cost alarm based LPG sensor.

- Highly Sensitive, Stable.

- Fast response / degassing time.

- Low cost fabrication & Protection.

- Technology transfer to Realty Automation & Security systems Pvt.Ltd.