With cars becoming more software-defined and electric drivetrains redefining architecture, embedded memory must evolve. STMicroelectronics’ latest innovation, Stellar with xMemory, enables memory extensibility within automotive microcontrollers, offering developers the flexibility to scale storage dynamically. In an exclusive virtual press briefing, Davide Santo, Senior Director of the Automotive MCU Business Unit at ST, to unpack the technical and strategic depth behind this solution.

What makes xMemory fundamentally different from conventional embedded memory approaches in MCUs?

xMemory introduces an entirely new level of flexibility to embedded memory architecture. Traditional MCUs come with fixed non-volatile memory sizes, and any change in memory requirements during development or after deployment typically necessitates a redesign of the PCB, a new qualification cycle, and significant costs and delays. With xMemory, that constraint is removed. Developers can scale the memory post-production, through software, while keeping the same hardware unchanged. This extensibility allows developers to anticipate evolving software needs without over-specifying hardware up front.

“xMemory allows post-production memory expansion—no redesign, no requalification, just software.”

What’s the role of ST’s PCM technology in enabling this extensibility?

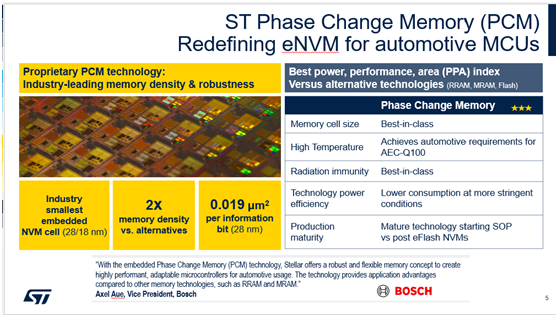

PCM, or Phase-Change Memory, is the enabler of this innovation. It’s ST’s proprietary embedded non-volatile memory with the smallest bit cell in the industry. This gives us a major density advantage—more than two times the storage compared to Flash in the same silicon area. But density is only part of the story. PCM also supports automotive-grade performance with up to 165°C junction temperature, low power consumption, and long-term data retention exceeding 25 years. It has also been validated for automotive reliability, making it robust for real-world applications.

How does Stellar with xMemory redefine memory architecture for software-defined vehicles, and what specific challenges in current EV development does it aim to address?

Stellar with xMemory allows automotive customers, specifically OEMs, even tier ones,of course, to start the development of an ECU and adapt to changes of functions that may happen during the development, most likely during the development, also in production without having to requalify the hardware part of the ECU, leveraging essentially only software update over theair.This is completely under the customer’s control. In other words, customers don’t have to go back and buy new parts or requalify the ECU because it all has been done at the beginning, and they can increment memory when they need to do so.

How does xMemory help with OTA (Over-the-Air) software updates?

OTA updates are a cornerstone of the software-defined vehicle strategy. With xMemory, developers can push new features, enhancements, or fixes to vehicles long after they are sold. Instead of being locked into the original memory footprint, xMemory allows the storage space to be extended dynamically to support these updates. This is critical for adding AI models, new diagnostics, cybersecurity patches, or customer-specific features without any hardware redesign.

What types of automotive architectures benefit the most from xMemory?

Any architecture that requires integration, flexibility, and evolving functionality will benefit. This includes electric vehicle drivetrain ECUs, zone controllers, domain controllers, and even body electronics. With the Stellar P series, for example, we support a wide range of traction and booster configurations, and xMemory ensures these ECUs can scale in capability without a physical redesign. It’s also well suited for software-centric architectures where centralized ECUs need to support a growing number of functions over time.

How does PCM compare to RRAM and MRAM in automotive applications?

PCM stands out because of its density, high-temperature operation, and maturity. Compared to RRAM or MRAM, PCM allows for a much smaller bit cell, which translates into higher memory density. It is also more power-efficient and has superior thermal endurance—up to 165°C—compared to other emerging technologies. Furthermore, PCM has undergone years of automotive-grade validation, so it’s not just promising in theory; it’s proven in practice

Does using more memory increase power consumption?

Not with xMemory. Thanks to the combination of PCM and ST’s Fully Depleted Silicon-on-Insulator (FD-SOI) technology, we ensure very low static and dynamic power consumption. Extending memory doesn’t affect leakage or operational efficiency. This is crucial for EV platforms, where power budgets are tight and efficiency is critical. So you get more capacity without added energy cost.

“More memory without more power—that’s a breakthrough for EVs and SDVs.”

How does xMemory support AI and machine learning at the edge?

Edge AI is resource-intensive. As models evolve, the amount of data and parameters they need to process increases. xMemory allows developers to expand non-volatile memory to accommodate larger or more complex models. This is particularly relevant in areas like driver monitoring systems, predictive maintenance, and localized sensor processing. It enables in-vehicle intelligence to grow without compromising performance or requiring platform requalification.

Are ST’s MCUs with xMemory compatible with existing tools?

We designed xMemory to be fully compatible with our existing toolchain. Developers can use the same software development kits, safety and security libraries, and automotive software platforms. xMemory is activated and managed through software-level control, and all its capabilities are documented clearly. It’s designed to be easy to use so that developers can focus on innovation rather than system integration.

What does the future hold for xMemory? Will it expand beyond automotive?

Automotive is our immediate priority due to the complexity and evolving needs of software-defined platforms. However, the benefits of xMemory—extensibility, density, reliability—are not exclusive to automotive. We see strong potential in industrial automation, edge computing, and smart infrastructure. Wherever real-time updates, system longevity, and flexible deployment are needed, xMemory could bring significant value.

Can xMemory help OEMs reduce qualification cycles and time to market?

By maintaining a single part number with scalable memory, customers avoid the need to requalify their design every time a software requirement changes. This streamlines ECU design, accelerates development, and significantly reduces the time needed to get a vehicle or feature into production.

What are the main differences between internal and external memory when it comes to automotive MCU design?

Internal memory is faster, more secure, and more reliable. External memory adds latency, increases system complexity, and introduces more points of failure. With xMemory, we allow internal memory to scale without adding cost or power burden. That keeps system architecture clean and responsive.

Will ST implement neural processing units (NPUs) in future xMemory-enabled MCUs?

We’re actively developing enhanced AI capabilities within our Stellar roadmap, including NPUs. The combination of scalable memory and dedicated AI processing will allow us to handle increasingly complex machine learning workloads at the edge. This will be critical for automated driving and in-vehicle intelligence.

Are there any limitations to xMemory extensibility?

The main consideration is upfront design planning. While xMemory allows post-production memory increases, developers need to account for future memory needs during the initial system design to ensure the right architecture is in place. That said, the flexibility it provides is unmatched compared to fixed-memory solutions.

What is the core value proposition of xMemory for OEMs building next-gen vehicles?

The core value is threefold:

- Innovation – OEMs can integrate more features and functions within the same budget and device size.

- Efficiency – A unified memory platform simplifies procurement and inventory.

- Faster time-to-market – Cars can be updated during development and post-sale, without waiting for a new hardware spin.

Ultimately, xMemory enables OEMs to build more intelligent, more adaptable, and more future-proof vehicles, while reducing complexity and development time.