Indian SMT industry has reported a radical growth rate is recent years, thanks to increasing electronics demand & growing EMS industry. Changing global landscapes in electronics design and SMT manufacturing capabilities and cost structures have turned the attention of global companies towards India. Companies from around the world are looking to build local capabilities in India not just to serve the resident market but also to cater to overseas markets. This has resulted in the development of indigenous capabilities across the SMT value chain in India. Some of the Industry experts commented on Future of SMT industry of India.

The Indian EMS industry estimated to be $68.31 billion by 2015. The impressive guidance between 2011 and 2015 for this industry expected to result in a Compound Annual Growth Rate (CAGR) of 9.88 percent. The corresponding size of the industry by 2015 is anticipated to be $94.2 billion.

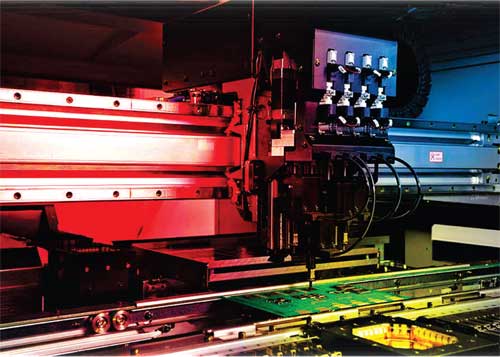

Today most of the globally major EMS companies have a presence in the country. The growing demand in manufacturing of electronic products directly influences the sale of surface mount technologies (SMT) equipment. The SMT equipment market is witnessing steady growth bolstered by the demand from various end user sectors such as communications, consumer, industrial, automotive and medical where electronics penetration has been on the rise.

Availability of cost effective and skilled labor has made India a global hub for EMS and OEM companies.

Some of the driving factors of SMT industry in India are:

1. 65 percent of current demand for electronics products met by imports. Imports are likely to grow from $28 billion in 2011 to $42 billion in 2015 in the absence of intervention.

2. High value added manufacturing is likely to be restricted to less than 7 percent in 2015. This represents a cumulative opportunity loss of $200 billion between 2011 and 2015 in the absence of intervention.

3. Increasing total domestic manufacturing to 50 per cent by 2015 will create additional direct employment for nearly 2 lakh people.

Future of SMT industry – Views from Industry leaders

ASM Assembly Systems India Pvt Ltd

Damodaran Periaswamy, Head of ASM Assembly Systems India

According to M r. Periaswamy, The SMT industry in India sees a bright future the key factor for the expected growth is due to post-election activities from the newly elected government, which indicate signs of economic growth for India in the coming years. For example, the fiscal management contains inflation and trade deficit as well as promises fresh regulations, which are at introducing policies that are more transparent and allows greater foreign ownership in infrastructure ventures for Indian economic growth. With the government promoting electronic manufacturing by funding or subsidies through the MSIPS (Modified Special Incentive Package Scheme) and approving setup of EMCs in key cities, in order to compete with China’s SMT industry, It is difficult to compare between China and India in terms of SMT manufacturing since there are no direct assessments. China has already established itself as the global leader in mass production and at quite high level in terms of use of SMT products and technologies. On the other hand, India is a very attractive country with big potential and various resources for all SMT manufacturers. Therefore, we see India as the upcoming bright market for the electronics manufacturers with increasingly high demand for electronics goods, especially automotive and telecommunication devices.

However, India can develop itself further by improving factors such as infrastructure development, tax policies and development of skilled labor.

DVS India Pvt Ltd

Mr. R. S. Gupta – DGM, Sales & Marketing

As per Mr. Gupta, SMT Industry in India will grow exponentially in coming years, the driving factors include growing demand of domestic and Industrial electronics, which is forcing domestic manufacturing to grow, that ultimately pushes SMT Industry to grow for all segments like, consumer, automotive, telecom and other fields as well. We can take up international standard jobs, but not all.

India has capability to take up International jobs and this is not new. Many SMT facilities are catering to export business other than domestic one. We can compete with Chinese vendors but not now. To do so India need to cross many hurdles i.e. Infrastructure, promotion from govt., local component manufacturing, logistics etc. Once all these are available for SMT manufacturing, I feel we can compete and even do better.

iNETest Technologies India Pvt Ltd

Pravin Joshi, Vice President Sales & Business Development

As per Mr. Joshi, yes SMT Industry will grow in India, provided correct Govt. Policies to boost Manufacturing. The New Govt. is yet to firm up policies, but we are very hopeful because this Govt. has an agenda for development & Electronics Mfg is on their radar to bring down the Fiscal Deficit.

Indian SMT industry is ready for international jobs, as there are many Indian companies have excellent facilities & Processes in Place & some MNCs of world repute are in India with their best facilities & Processes. We are at par in terms of manufacturing facilities in India as many times we sell first latest machine or latest technology from the equipment manufacturer to customers in India. To cater

Chinese competition, we are not ready, unless we have mass scale of manufacturing supported by Govt. Policies to boost manufacturing & backed up by Infrastructure facilities. There is a Long way to go. As a Distributor, we would love to have Manufacturing Facilities with multiple lines of 10 or 20, but it is a wait for more than last 14 years.

Juki India Pvt. Ltd.

Mr. Praveen Madaan, Country Head (SMT Division)

As per Mr. Madaan, SMT Industry will grow for sure. Main driving factors will be Govt. policies, FDI in semiconductor manufacturing in India, higher duties on finished products, lower duties on import of SMT equipment’s, availability of cheaper loans from the banks, higher incentive for exports and encourage local R&D and product designs. In international business, based on my one-year experience in India 90% of the SMT Manufacturing facilities in India do not meet international Standards. India is not ready yet to take up International job work except few multinational EMS and Automotive companies.

Govt. should build few electronic manufacturing hubs with excellent infrastructure, lease the factories to investors with package of lower rental, and lower interest rates. To attract international customers Quality, Commitment, Facility and Prices are the key factors. India has the potential to beat Chinese leadership for SMT manufacturing.

10-15 years is realistic period if Indians have right mindset, Commitment towards quality, and strong political support. Indians should focus more on their strengths to overcome China.

Leaptech Corporation

Mr. Suresh Nair, Director

Commented by Mr. Nair, the domestic market growth will fuel the growth of SMT industry aided by the new initiates taken by the government to promote electronics hardware manufacturing locally.

Indian facilities definitely meet the international standards of accuracy, though it may not have high-speed facilities as of now due to relatively low volumes. Indian industry is already doing lot of international job works and we do have the capability for sure. As far as competition with china is concerned, it is difficult to give clear comment, but Yes, if we can have good component manufacturing base and FABs locally.

Maxim SMT Technologies Pvt. Ltd.

Mr. S. S. Bist, General Manager

As per Mr. Bist, for SMT industry growth in India the important concern is foreign investments. India’s new policy already begins accepting applications for the investments through its recently announced Modified-Special Incentive Package Scheme. This will help lots of international companies to move towards India. For international business, there is a good presence of foreign multinational companies in India, for cheap labour. The Indian engineers are good, if not equal, and in some cases, better. The India lacks a semiconductor fab that would go a long way in helping local electronics manufacturers. For competition with china, since China is home to some of the largest electronics manufacturers and components manufacturer, hence the demand and supply circle completes domestically saving lots of currency, time & efforts.

India cannot beat Chinese leadership in electronic manufacturing but it may be good for India to focus on its strength, which is Electronics System Design, drive IP and product creation, where India can take lead in coming years.

PROSEM Technology India (P) Ltd.

Mr. Vinit Verma, Director

As per Mr. Verma, we strongly feel that the SMT industry should show some growth this year. Of course, for that to happen, support from the government in terms of manufacturing friendly policies will be required such as increasing import duty on finished electronic goods, etc. If this happens, it will drive the SMT industry in India. Very few Indian manufacturing facilities have the required infrastructure and systems in place to meet the international standards. This is a vicious circle. Since the volumes are not enough, the EMS companies find themselves unable to invest heavily on the infrastructure and systems to meet the international standards. Hence, the business volumes have to grow. For that to happen, the manufacturing sector has to give incentives – direct and indirect. Also for the SMT manufacturing to grow, back-end Semiconductor Fabs need to be setup in India. For that to happen, again, special incentives should provide to those willing to setup their Fab units.

VI Technology Ltd.

Mr. Rakesh Shetty, Business Development Manager

As per Mr. Shetty, SMT Industry in India will grow in coming years, with the changes in government policies and encouraging manufacturing sectors in INDIA will stimulate the growth. Nevertheless, as always the growth will be a slow and steady one. The SMT manufacturing facilities in INDIA today understand and meet the international standards. In fact, we have many of our customers catering to International clients and growing year on year. See a huge potential on this as a lot of untapped market internationally. For competition with chine, we cannot compare China to India in terms of the SMT manufacturing, as both the markets are different. China market is largely a very manufacturing industry, whereas as in INDIA it is a low to medium volume market. China has an advantage that the infrastructure is already in place and ready for more whereas India is yet to tap this volume-oriented game.

American Tec India

Mr. Rajendra Singh, General Manager

As per Mr. Singh, SMT Industry in India will grow, that is for sure. The driving force is our huge market/consumption. Our Government is also serious about the local manufacturing and some of the positive steps taken. India was ready for International job works a long ago and there are many Indian companies doing good job and growing. We do not have any doubts about the capability of the SMT industry in India; it is world class in terms of quality standards, accuracy and on time delivery. For Chinese competition, today we are not mass manufacturer of electronics but China is! In fact, China is the manufacturing hub for the whole world, today our first priority is to be a supplier for our own consumption and that is a very large volume of business. Once we are able to fulfill the manufacturing requirement of our own country, then we can think of the leadership role.

Nordson Advanced Technology – Electronic Systems

Mr. Shivakumar, Business Development Manager

Commented by Mr. Kumar, SMT industry will definitely grow. With India planning to manufacture Wafer Fabs, it expected to provide growth fillip to the advanced packaging industry. As the advanced packaging industry grows, SMT industry will be the direct beneficiary. For international jobs, there are a few good facilities in India. However, predominantly, the drive is towards a low cost solution. There are companies already doing good quality International Job Work. It may take couple of years to have a larger pool of companies with the necessary facilities. As far as completion with china is concerned, In terms of quality – yes. We are already having vendors with good quality capability, but In terms of volume – not in the near future.

OK International

Mr. Dilip Rane, Country Manager

As per Mr. Rane, SMT industry will grow in India; the increased demands in automotive and electronic consumer goods as well as the miniaturization of components are key drivers. The Semiconductor Industry that is relentlessly pursuing product innovation to deliver high end solutions drives the SMT Industry. Indian Industry does pursue and meet international standards as part of their contract processes. Like their international counterparts, SMT players in India have the ability to deliver speed and accuracy in order to meet their customer needs. Indian SMT Industry’s key strengths are its capability and flexibility to deliver, and to fulfill international contracts. As far as competition with Chinese market is concerned, Indian Industry should remain focused on what they do best rather than looking at beating someone. The market will drive where the core competencies are for specific requirements. The long-term prospects are looking good in this fast growing market.

Panasonic India pvt Ltd

Mr. Vishal Dahiya, DGM, Factory Automation

Commented by Mr. Dahiya, The SMT industry will grow significantly in future, the driving factors will be Govt Direction & initiatives to boost manufacturing in India & India’s demand in Defense, telecom & consumer Sector. India is ready for international job works with some limitations.

Currently India’s manufacturing facilities are up to international standards in terms of quality & productivity. Nevertheless, for speedy delivery Govt. policies & infrastructure plays major role & we need to improve on that. If our Govt. take effective steps, our industry can beat Chinese leadership for SMT manufacturing by next 5 years.

NMtronics India Ltd.

Mr Soni Saran Singh – Executive Director

As per Mr. Singh, the SMT industry will grow as we can see favorable policies from Govt. to support the industry. The Govt. seems to support local companies that will enhance our inhouse capabilities and will give a continual growth path to Indian SMT industry.

As far as international jobs are concerned, it is difficult for Indian industry at this point of time, as internationally the standards goes sometime very difficult, and it is not possible for a vendor to upgrade its facilities for 1 or 2 international clients, unless long term relations are involved. Despite our focus should be to cater our domestic demands in-house, that is easy for our industry as we know the trends & requirements, infrastructures are comparatively easily available, and also in domestic jobs the risk factors of recessions, etc is very less as compared to international markets. Apart from that, whenever

Indian industry goes for bidding for international jobs, a confidence could be built among global market, as we are a large importer of electronics and have-not meet our in-house demand-supply landmarks. In our opinion, the route to international jobs goes from catering domestic jobs in-house. For Chinese market, we are ready to beat them. As if you see a general Chinese product, they do not have any quality standard, but in India, for any level of jobs, we maintain at least some quality scales. At present china is leading the global market, because they have very flexible Govt. policies and hence very high volume capabilities.

Whereas in India policies still firm. A support hand from Govt. is required for Indian SMT industry to set out ways to a developed industry structure.

Trans-Technology Ind. Pvt Ltd

Mr. Amit Madan, Country Manager

As per Mr. Madan, the SMT industry has grown in the past few years and is bound to expand in terms of local manufacturing, foreign manufacturers looking to invest massively in the projects that were thought long time back. Key development would be government-taking measures to control the CAD (current account deficit) which needs to narrow down. Commenting on international business, SMT industry in the past few years had witnessed a massive adoption of various compliances certifications, which serves rulebook to maintain quality standards, but not at the cost of missing competition. Going by the skills set available and increasing consumer demand in the quality products, I personally believe that given the opportunity and mindset of self -sufficient, we can take upon the job work for the international standard. On competition with Chinese market, Indian industry involved in electronics has to face many hurdles, delays, mood swings – this makes us inefficient to cope up with the market which china is dominating.

Conclusion

Much of the domestic electronics consumption in the country served through imports. Electronics imports which are currently the third highest, next only to crude and gold, accounted for nearly $30 billion in 2012, and forecasted to scale past $50 billion in just 3 years. In India, total market of electronics estimated to be $44.81 billion in 2012, representing a growth of 7 percent over the previous year. The TM expected to grow at a CAGR of 11.5 percent and reach revenues of $64.85 billion by 2015. Total domestic market for 2012 estimated to be $17.07 billion, representing a growth of 11% over 2010.

These figures simply signify the bright future of SMT industry in India.