By Mr. Abhishek Shukla, Marketing and Vendor Development, Saison Components & Solutions

Fuel cells are no longer an “if” technology, but a “when”, and that “when” is today.

The technology began to gain traction over a decade ago when fuel cells showed that they fit well in a range of early applications, competing head to head with incumbent technologies. Fuel cells have demonstrated their versatility as a reliable and clean power generation source in a number of sectors, including forklifts, data centres, EV and telecom towers, as well as growing popularity as an onsite, low-emission power source for retail stores and corporate facilities. Fuel cell power generation is becoming more widespread, with more than a hundred thousand fuel cell systems operating worldwide.

Now the question is what fuel cell is & why fuel cell sales leases increasing in end-user markets?

The technology is versatile and reliable, capable of producing power for anything that needs it, whether it is a motive, stationary, off-grid, or portable application. Fuel cells are a low-to-zero emission technology, producing energy electrochemically without combustion, and typically exempted from state air permitting requirements.

Fuel cells utilize hydrogen, which can be extracted from virtually any hydrogen-containing source, including conventional (fossil fuels) and renewable resources (biogas, biomass, solar and wind). Given these diverse sources of hydrogen, a synergy exists between fuel cells and both the renewable and fossil fuel industries. As the fuel cell and hydrogen industries continue to grow, market expansion opportunities will also expand for these sectors.

Applications of Fuel Cell

Fuel cells have been researched and developed for use in several applications. From being used in transportation applications including automobiles, buses, utility vehicles, and scooters and bicycles for continuous power supply power, so for vehicle acceleration and other increased power needs

Fuel cell are also used in Backup power systems provide power when the primary power source is disrupted. Some backup power applications include computer systems, manufacturing facilities, homes, and utility substations

Fuel cells for stationary applications have been used commercially for over twenty years. Stationary fuel cells can be used as a primary power source. It is often used to power houses that are not connected to the grid or to provide supplemental power.

Fuel Cell Technology

All fuel cells are based around a central design using two electrodes separated by a solid or liquid electrolyte that carries electrically charged particles between them. A catalyst is often used to speed up the reactions at the electrodes. Fuel cell types are generally classified according to the nature of the electrolyte they use. Each type requires particular materials and fuels and is suitable for different applications. The fuel cell products are currently developing include PEMFC (Proton Exchange Membrane FC), DMFC (Direct Methanol FC), MCFC (Molten Carbonate FC), and SOFC (Solid Oxide FC).

VINATech’s catalyst support, catalyst and MEA products are suitable for PEMFC and DMFC.

VINATech, producer of catalyst support and catalysts for fuel cells and MEA (Membrane Electrode Assembly).

VINATech supplies catalysts and MEA having an excellent corrosion resisting property. These properties improve the life cycle of fuel cells by using crystalline carbons as a catalyst support.

Features of VINATech’s fuel cell catalyst supports product

Fuel cells require micro catalyst particles 3 nm or below, to improve their catalytic performance. But the Small particles cannot be created only with catalysts, the Catalysts have to be distributed on a catalyst support.

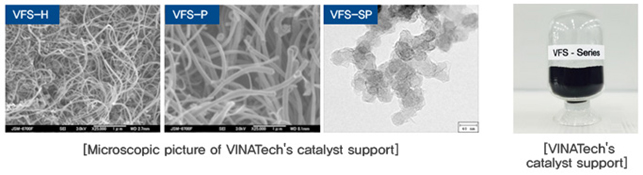

VINATech’s fuel cell catalyst supports are CNF or crystalline carbon-black products which are designed to minimize the shortening of catalysts’ life cycle.

Carbon is seen to corrode easily at 1.2 V or above .Corrosion of carbon contained in catalyst supports results in deterioration of catalysts’ performance and shortening of the fuel cells’ life cycle.

Features of VINATech’s fuel cell catalyst products

VINATech’s fuel cell catalysts are made of platinum, forming 2.5 to 3.0 nm particles that are characterized by broad reaction areas and excellent corrosion resistance, which results in High durability (using VINATECH’s supporter), High ESA(Electrochemical Surface Area), High conductivity.

Features of VINATech’s fuel cell MEA

VINATech’s fuel cell MEA features excellent performance in discharging generated water, aided by less-than 100 nm electrode porosity controlling technology. This product is suitable for improving the performance and life cycle of fuel cells.

Application areas of VINATech’s fuel cell components

VINATech offers combined solutions including Catalyst support components, catalysts and MEA, optimized to the customer’s application area and specifications. In particular, for MEA, wafer special catalyst support and custom-tailored catalysts for customer’s application areas and requirements.