MacDermid Alpha Electronics Solutions, a global supplier of integrated solutions from our Circuitry, Assembly and Semiconductor divisions that provides unmatched capabilities in electronics design and manufacturing, has announced that Electrolube will be showcasing new solutions from their extensive encapsulation resin, thermal management and conformal coating portfolios in Hall 14 stand PB55 at Productronica India, held on the 21st-23rd September at the India Expo Mart in Greater Noida.

To highlight the wide variety of industry sectors they serve, Electrolube has selected their most popular products that have seen unrivalled success in Automotive and EV manufacturing, 5G applications, Solar power projects, Consumer Electronics and LEDs. In each of these respective manufacturing sectors, Electrolube offers a diverse range of resin, thermal management and conformal coating products that serve nearly every requirement for electronics reliability and protection. Electrolube will also highlight brand- new sustainable bio-based resins and coatings, illustrating their high performance in harsh environments and greener credentials.

Electrolube’s GF400 is a two-part, liquid silicone based gap filler that provides excellent thermal performance (4.0 W/m-K). With a wide operating temperature range between -50 to +200°C and non-flammable, GF400 is a dispensible material that can be applied to help dissipate heat from complex geometries. After curing, it forms a low modulus elastomer that can also relieve CTE stress during power cycling. The properties of GF400 make it one of the highest performing thermal management products for managing heat dissipation in data and telecom network applications. The advantages of GF400 showed a lower coefficient of expansion, lower modulus, better long-term reliability and improved cost performance, pushing it to the forefront of thermal management offerings for the connected world.

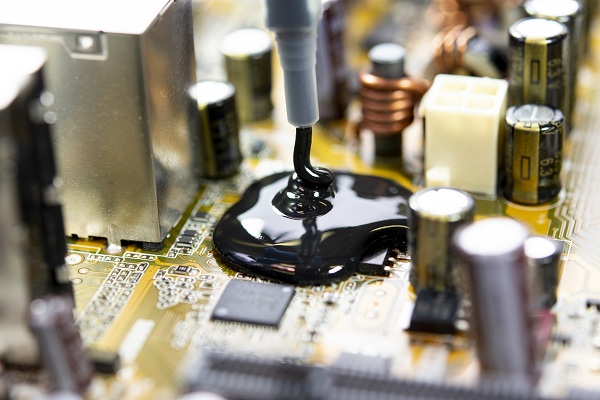

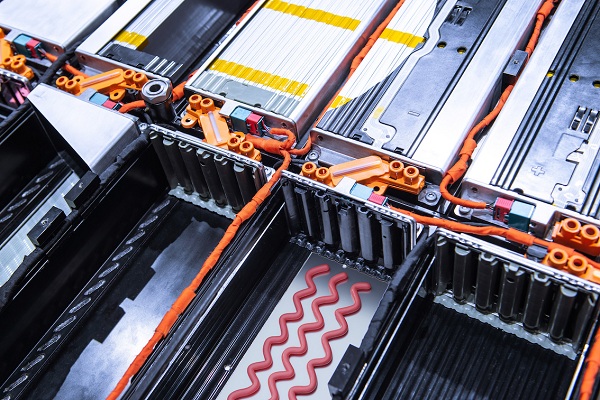

Electrolube’s Thermally Conductive Epoxy Potting Compound, ER2221, is a highly thermally conductive resin with low viscosity, ideal for potting cells within electric vehicle batteries. The UL94 V-0 recognised epoxy potting compound can withstand long durations at high temperatures and can assist with securing cells in place whilst dissipating the heat away to the surroundings. ER2221 is coloured black with a maximum operating temperature of 150°C and an advanced thermal conductivity value, in comparison to other encapsulants, of 1.20W/m.K.

The advanced conformal coating, UVCLX, is the first of its kind globally. UVCLX is a solvent-free, bio-based conformal coating that provides the highest levels of protection in a rapid processing time. Applied via a selective coating machine, UVCLX has been created with a high percentage of organic bio-based content obtained from renewable sources and exceeds traditional UV Cure Coatings by being touch dry after just a short exposure to LED-365nm UV light. UVCLX guarantees full cure in less than 24 hours due to its secondary chemical cure mechanism, which even cures shadowed areas in a matter of hours. UVCLX significantly improves production time and provides even higher levels of performance, including resistance to cracking during thermal shock cycling.

Padmanabha Shakthivelu, General Manager of Electrolube India, said, “Productronica India provides an excellent opportunity to share our expertise in conformal coatings, thermal management materials and resins. With our offices and warehouse located in Bangalore, we are in an excellent position to offer a fast and responsive ‘complete package’ of electro-chemical protection solutions for the electronics manufacturing community in India.”

MacDermid Alpha Electronics Solutions enables electronics interconnection through the innovative specialty chemicals and materials from our Alpha, Compugraphics, Electrolube, Kester, and MacDermid Enthone brands. We serve all global regions and all steps of device manufacturing within every segment of the electronics supply chain. The experts in our Semiconductor Solutions, Circuitry Solutions, and Assembly Solutions divisions collaborate with OEMs and fabricators in the implementation of new technologies that redefine what is possible in device design. Our world class technical service is constantly at hand to ensure optimized outcomes in yield and productivity. Our solutions can increase throughput, reduce carbon footprints, lower total cost of ownership, and enable electronics innovation.

For further information, http://www.electrolube.com.