Global Electro-chemicals and circuit protection specialist, Electrolube has today announced the development of a highly innovative X-ray proof encapsulation resin. Using key local knowledge, Electrolube’s Indian team has embarked upon the development of the ground-breaking new resin following specific customer requests. Electrolube’s Research and Development teams are based at three locations around the world – UK, China and India, ensuring group collaboration and technical support at all junctures.

Global Electro-chemicals and circuit protection specialist, Electrolube has today announced the development of a highly innovative X-ray proof encapsulation resin. Using key local knowledge, Electrolube’s Indian team has embarked upon the development of the ground-breaking new resin following specific customer requests. Electrolube’s Research and Development teams are based at three locations around the world – UK, China and India, ensuring group collaboration and technical support at all junctures.

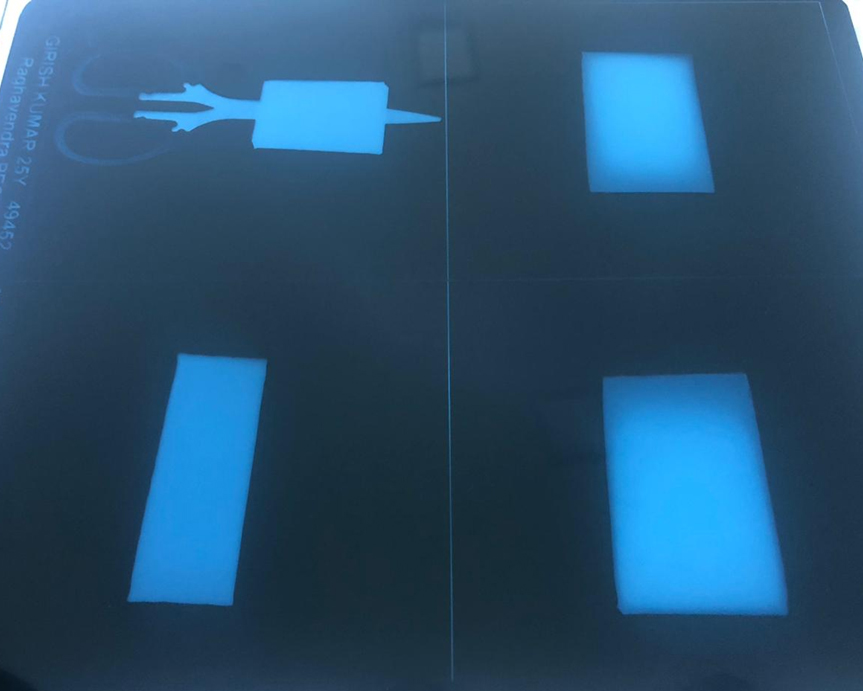

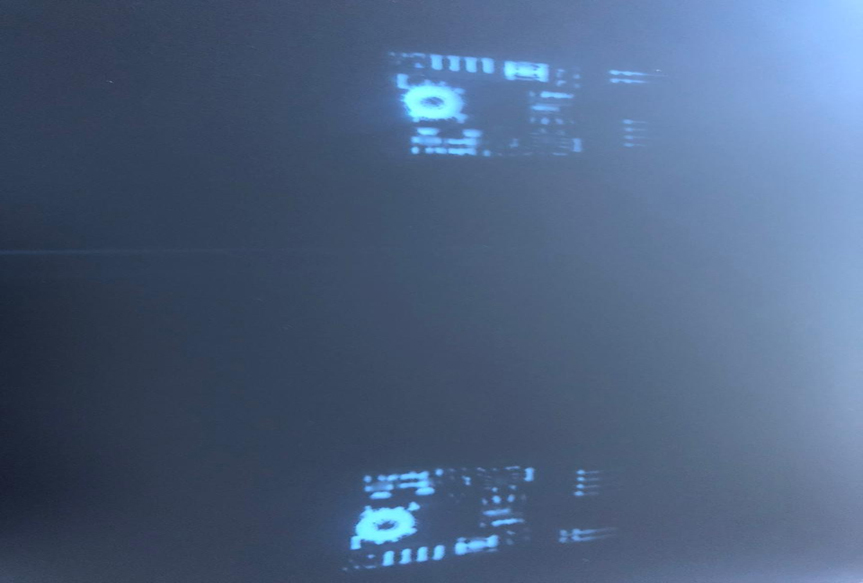

ER6010 is an X-ray shielding epoxy resin that has been developed for the encapsulation of ‘Mission’ critical applications requiring complete protection and concealment of PCB and components. For example, some Defence or Military based projects are swathed in high levels of confidentiality and the designs of the PCBs must be protected at all cost. Electrolube has worked closely with these customers and understands the requirement for a highly specialised resin that protects the security of designs and circuits, even under the medium of X-ray.

This brand new encapsulation resin is a two part thermally conductive system that exhibits good flow characteristics, facilitating the potting of even the most complex and difficult geometries. ER6010 has a wide operating temperature range of -40 to +160oC and a thermal conductivity of 0.53 W/m.K. This epoxy offers good chemical resistance and a high level of protection in a range of different environments. The cure time is 24 hours, at 23oC but this can be accelerated with heat. Following encapsulation of a circuit with ER6010, the circuit components and design features are completely protected allowing complete confidentiality.

This brand new encapsulation resin is a two part thermally conductive system that exhibits good flow characteristics, facilitating the potting of even the most complex and difficult geometries. ER6010 has a wide operating temperature range of -40 to +160oC and a thermal conductivity of 0.53 W/m.K. This epoxy offers good chemical resistance and a high level of protection in a range of different environments. The cure time is 24 hours, at 23oC but this can be accelerated with heat. Following encapsulation of a circuit with ER6010, the circuit components and design features are completely protected allowing complete confidentiality.

Manufactured in Bangalore, this innovative and highly specialised new resin is made from locally sourced materials, and will carry a full ‘seal of approval’ from the UK parent company for quality and innovation that meet internationally recognised standards.

Electrolube India’s General Manager, Padmanabha Shaktivelu comments, “We are earning a solid reputation for our problem solving capabilities in India, in addition to being able to offer some of the world’s best electro-chemical products, all backed by fast lead times and first class technical support. This new resin is a prime example of the problem and solution approach that Electrolube adopts. Our bespoke solutions are eagerly being sought after by local manufacturers, particularly as the industry seeks expert guidance to help improve processes, productivity and ultimately the quality and reliability of their end-products.”

For further information, please visit www.electrolube.com.