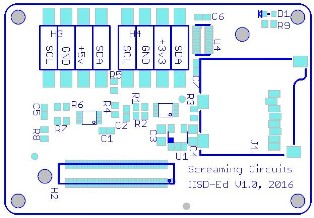

As PCB assemblers, we’ve been asked the question,”do I really need soldermask and silkscreen” many times. And, we’ve been asked with good reasons. To us, soldermask protects exposed metal, reduce the chance of shorts and keeps solder where solder needs to be. Silkscreen removes ambiguity, ensuring that parts go where parts need to go, and that they are pointed the way they need to be pointed.

As PCB assemblers, we’ve been asked the question,”do I really need soldermask and silkscreen” many times. And, we’ve been asked with good reasons. To us, soldermask protects exposed metal, reduce the chance of shorts and keeps solder where solder needs to be. Silkscreen removes ambiguity, ensuring that parts go where parts need to go, and that they are pointed the way they need to be pointed.

But, that’s just the Screaming Circuits perspective. Right? Doesn’t leaving mask and silk off dramatically reduce the cost? On the surface (pun somewhat intended), leaving off the soldermask and silkscreen seems like it reduces cost. You can buy boards that way for less money. That’s the short answer — and the incorrect answer according to probably all assembly service providers.

If you’re hand building your own boards, it may be a viable option, but it can lead to so many other problems down the road, we recommend always having a soldermask. Always.

Without soldermask, solder can migrate off the pad, on to the traces or down into vias. The amount of solder paste we put down on a surface mount pad is based on making a good solder joint and having solder mask to prevent that migration. Some PC board metal surfaces will corrode if not covered with either solder or solder mask. And it’s a lot easier to short something in operation with all of that extra exposed metal.

What About Silkscreen?

Shouldn’t all of the automation render the need for silk screen an obsolete requirement? In theory yes. In practice, no. Even though we have a nice set of industry standards, the adoption of those standards is sporadic enough that we simply can’t rely on data to be accurate. There’s still a lot of human work and too much ambiguity due to poor use of standards in marketing.

The only exception with silkscreen is having a good assembly drawing. If you have a detailed assembly drawing, with all reference designators, part outlines and polarities clearly marked, you can get away without silkscreen. Some people like to put other information on the board, like instruction or port identifications. In cases like that, all the reference designators can make the board unreadable. If you need that, provide an assembly drawing.

Duane Benson is the Chief Technology Champion at Screaming Circuits, a prototype PCB assembly electronic manufacturing company in Canby, Oregon