Filip Schiettecat, Senior Director Industry Management, Siemens PLM Software

By definition, the food and beverage industry is fast moving and always changing; milk goes off, bread gets eaten, and we want to eat more salads in the summer.

By definition, the food and beverage industry is fast moving and always changing; milk goes off, bread gets eaten, and we want to eat more salads in the summer.

But the combination of changing consumer demand, increasing regulation, complex supply chains for global sourcing and distribution, and competition from agile new competitors means food and beverage companies have to move faster than ever. And they have to do all that while still keeping quality high and appealing to customers who want products that suit them perfectly – whether that means gluten-free, low sugar or even custom flavours. Market predictions say there will be more changes in consumer packaged goods in the next five years than there have been in the last fifty. The only way to keep up is digitalization, which is your best opportunity to reduce time to market, improve efficiency and get ready for the future of manufacturing.

It’s very common for food and beverage companies to be fragmented; that’s not just different departments like product development and marketing, but different product lines will come from different teams who just aren’t connected. If you make both pasta and cheese, they might end up in the same shopping basket and even on the same plate, but if there’s poor communications between the teams behind them you miss out on opportunities to save time and money by sharing information about suppliers and ingredients, process technologies and the shopper who’s buying both of them.

Even within the same product line, entering the same information about ingredients over and over again at different stages of the process means the chance to make a mistake every time that information gets recorded. Using a digital thread means informationonly needs to be entered once and can then be re-used at every stage of the process: from creating the first model of the product that allows you to calculate its nutritional profile, throughfinalising the product formula and recipe in the lab, to monitoring the whole manufacturing chain and tracking those ingredients from multiple suppliers all the way to your final customer. This kind of traceability is key for keeping products consistent and delivering high quality, as well as being able to comply with regulations and keep recalls as limited and transparent as possible.Managing all of this digitally also saves you money and time.

Even within the same product line, entering the same information about ingredients over and over again at different stages of the process means the chance to make a mistake every time that information gets recorded. Using a digital thread means informationonly needs to be entered once and can then be re-used at every stage of the process: from creating the first model of the product that allows you to calculate its nutritional profile, throughfinalising the product formula and recipe in the lab, to monitoring the whole manufacturing chain and tracking those ingredients from multiple suppliers all the way to your final customer. This kind of traceability is key for keeping products consistent and delivering high quality, as well as being able to comply with regulations and keep recalls as limited and transparent as possible.Managing all of this digitally also saves you money and time.

Driven by fashion, social media, broadening interest in different cuisines and increasing concerns about health and allergies, consumer habits and tastes are changing faster than ever. Shoppers want new and interesting products; they want high quality and low prices on everyday items. They want detailed information about what they’re buying, from where and how it was grown to nutritional and allergen information. They want to know if a fruit snack is made with whole apples, apple puree or freeze-dried apple powder.One day a consumer might be looking for products with alternatives to sugar; next week they might be concerned about artificial sweeteners.

They want more choice of products, in exactly the right pack size for them. They even want custom products, whether that’s a new flavour of an old favourite, a low-calorie or allergen free option or personalised packaging. Mixing up different soft drink flavours in a phone app, 3D printed chocolate souvenirs from your holiday or a pack of cookies with your name and design printed on them might be novelties today, but they’re a sign of the trend to more and more differentiation.

They want more choice of products, in exactly the right pack size for them. They even want custom products, whether that’s a new flavour of an old favourite, a low-calorie or allergen free option or personalised packaging. Mixing up different soft drink flavours in a phone app, 3D printed chocolate souvenirs from your holiday or a pack of cookies with your name and design printed on them might be novelties today, but they’re a sign of the trend to more and more differentiation.

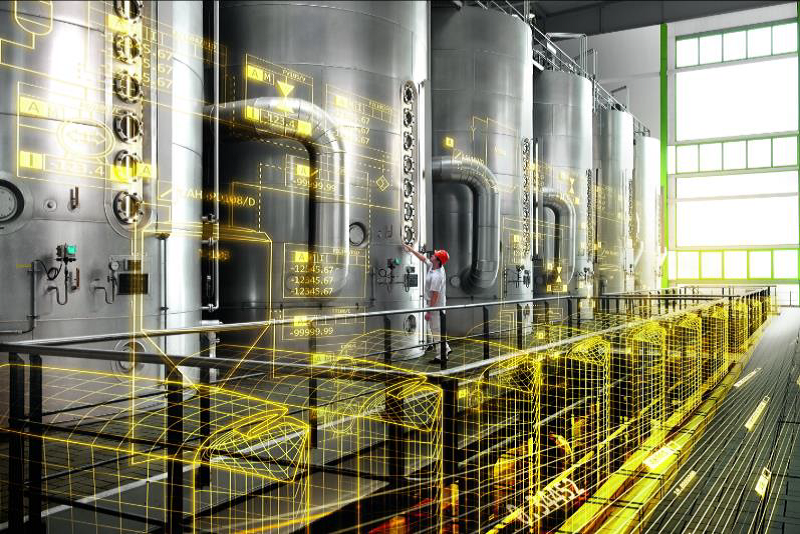

To meet those market demands, you need to develop multiple product variations, which may require different production lines – often more products and processes than you can create and test with traditional methods. Again, digitalization is the way to cope. Creating a digital twin for new products and the processes you’ll use to manufacture them lets you design and simulate product performance to make sure every new variant meets compliance regulations and market needs before you even prototype it at lab scale, so you can scale up quickly, manage testing in production to make sure your production matches what was designed, and track which ingredients from which source make it into which product shipped to which customers. A digital twin can reduce how long it takes to get a new product onto the market by up to half.

At the same time, the price of raw materials is rising, as are the numbers of regional and global regulations. The EU, for example, is currently proposing rules to increase consumer transparency for ingredients like enzymes and flavourings,GMOs, food and feed additives, smoke flavourings and even food contact materials, as well as cracking down on companies who use the same advertising for products made with different ingredients in different countries.

Food and beverage companies need to track and label ingredients for an ever-increasing variety of products and recipes, coming from different suppliers and shipping into different markets around the world through multiple supply and distribution chains. Paper-based processes simple can’t handle the scale and complexity.The bigger your product portfolio, the more variance, volume, complexity or different country regulations you deal with, the more digitalization can help. It’s also a key first step to prepare for the future.

That future is digital food: not the food pills of science fiction but wine, beer, cheese, meat and vegetables that have been tracked from the field and farm into the factory for consistent quality.

Using sensors and automation to handle the milk arriving in a dairy and the fermentation of the cheese it’s used to makecancut production time in half and reduce energy costs without compromising quality. Digitizing cellars and fermentation tanks gives brewers better control over temperatures as well as telling them when they can decant a batch of beer and clean the tanks, given them more time to experiment with beer recipes and letting them brew more varieties of beer without needing to buy more equipment. Recording the pesticide levels in the vineyard and sending alerts if the temperature in a fermenting barrel of wine is too high or too low keeps costs down and the quality of the final bottle of wine up.

This kind of sophisticated monitoring and automation may be the exception rather than the norm today, butcan you count on your competition not making those investments? To benefit from this kind of flexibility, consistent quality and reduced costs for your own processes, and to get your share of market opportunities that 3 billion new customers will generate by 2020, it’s time to start implementing your digitalization strategy now.