Demonstration of high-efficiency maintenance through visualization of equipment condition with Daikin Industries, Ltd.

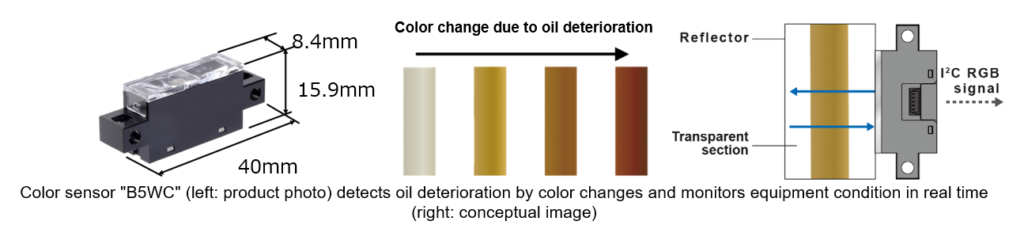

OMRON Corporation (HQ: Shimogyo-Ku, Kyoto. President and CEO: Yoshihito Yamada) has announced the global release of its B5WC Color Sensor for industrial embedding that detects slight color changes and differences. It also monitors real time oil deterioration in hydraulic equipment*¹ using colors to monitor the condition of the oil. Providing maintenance at optimal timing is indispensable for manufacturers. In addition, minimizing production losses within a manufacturing site contributes to carbon neutrality. The B5WC offers an innovative solution to these issues indicating OMRON’s strong direction of co-creating solutions with customers to solve social issues.

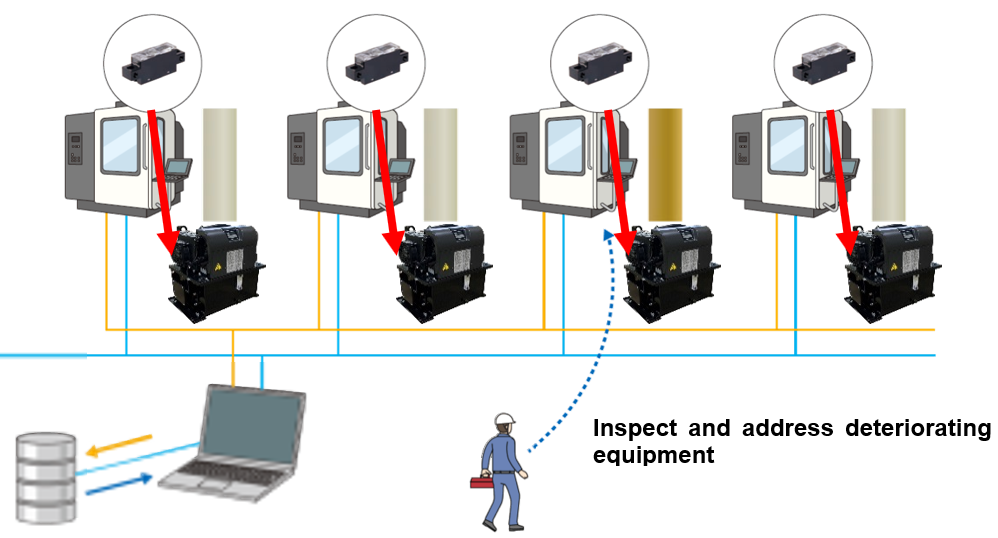

There are several issues that impact manufacturing sites. Oil contamination is frequently a cause of failure of industrial machinery and hydraulic equipment. Maintenance personnel are relied upon to conduct a visual check for such contamination, often by performing periodic inspection and part replacement based on their intuition, tricks, and experience. Often production stoppage losses due to sudden equipment breakdown are incurred by inconsistent judgment from each person in charge. In addition, delays in inspection timing have been a longstanding challenge. An increasing need is also being sensed for higher efficiency in maintenance and remote monitoring due to a severe shortage of labor and limited mobility caused by the COVID pandemic. However, size and cost of additional components have stood in the way of solving the problem.

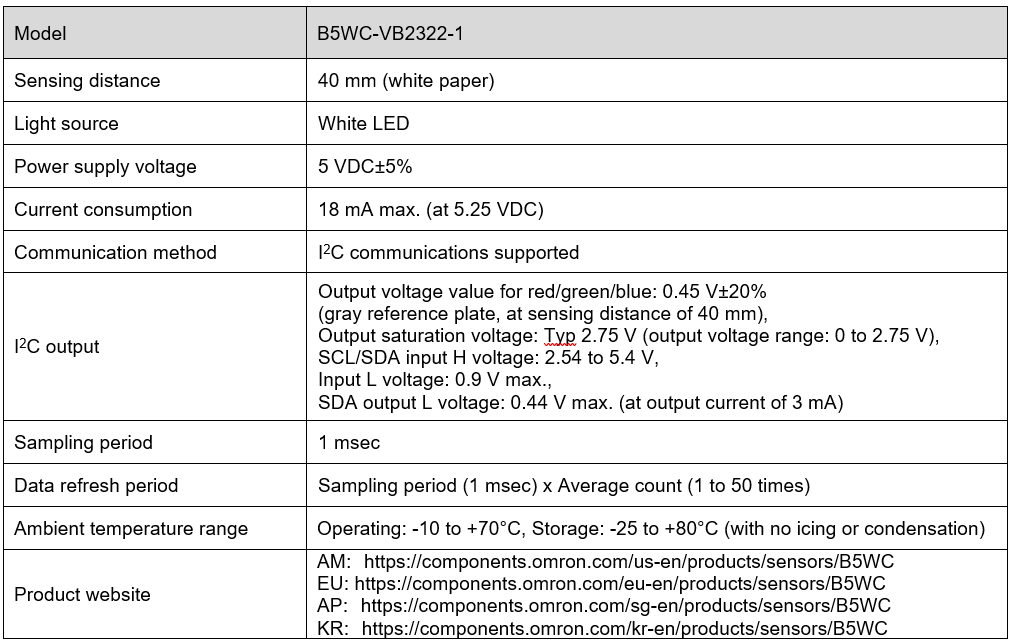

OMRON “B5WC” sensor can be embedded in the equipment that can quantitatively monitor oil deterioration based on color changes. Utilizing OMRON’s strengths in sensing technology and optical design technology, the new product can be easily integrated into the equipment because of its compact size (W:40mm x D:8.4mm x H:15.9mm) and communication method (I2C). This sensor helps customers to remotely monitor equipment in deterioration in real-time thereby leading to the visualization of the equipment and the reduction of man-hours required for inspection and maintenance. It also offers solutions to solving problems faced by the industrial machinery and hydraulic equipment industries through highly efficient and systematic maintenance.

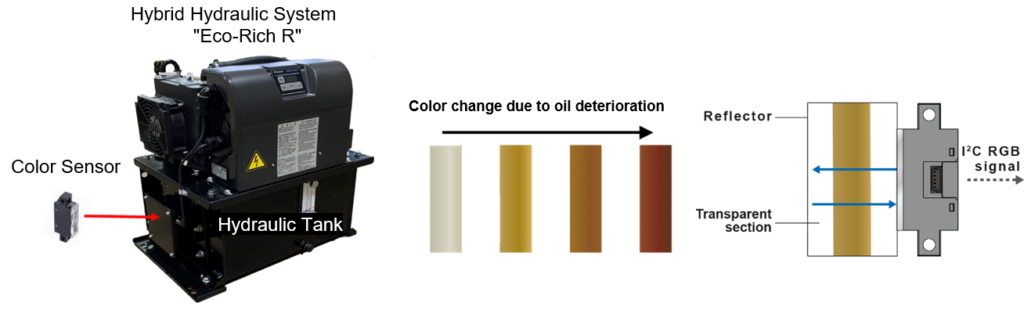

In preparation for its introduction, the B5WC has been undergoing field tests since April 2018 on the “Eco-Rich R”*2 hybrid hydraulic system provided by the Oil Hydraulics Division of Daikin Industries, Ltd. to solve issues through co-creation by the two companies. The Oil Hydraulics Division of Daikin Industries, Ltd. supports automation and energy conservation of industrial machinery, which plays a fundamental role in manufacturing, through hydraulic systems with advanced energy-saving performance that utilize motor and inverter technologies cultivated in the air conditioning business. Hydraulic fluid in the hydraulic system was inspected and changed about once a month by plant maintenance personnel. By combining the knowledge and expertise of the two companies,

a solution has been created that visualizes the state of oil deterioration in hydraulic equipment and achieves maintenance at the optimum time through unified management in the plant’s centralized control system. Furthermore, it contributes to the realization of carbon neutrality by minimizing losses associated with production stoppage and energy consumption due to sudden failures of hydraulic equipment caused by oil deterioration.

OMRON aims to continue to create and globally provide solutions based on advanced devices and modules to solve social issues through its customers’ products and services.

*1 Hydraulic equipment: Equipment used to power machine tools in factories as well as power shovels and tractors. Daikin Industries, Ltd. has achieved energy savings in machine tools with a hybrid hydraulic system that combines motor and inverter technology cultivated in the air conditioning business with hydraulic control technology. https://www.daikin.com/corporate/overview/business/pmc

*2 Hybrid hydraulic system “Eco-Rich R”: Hybrid hydraulic system developed by Daikin Industries, Ltd. mainly for factory machine tool applications. https://www.daikinpmc.com/en/special/ecorichr/index.html

Field Testing with Daikin Industries, Ltd.

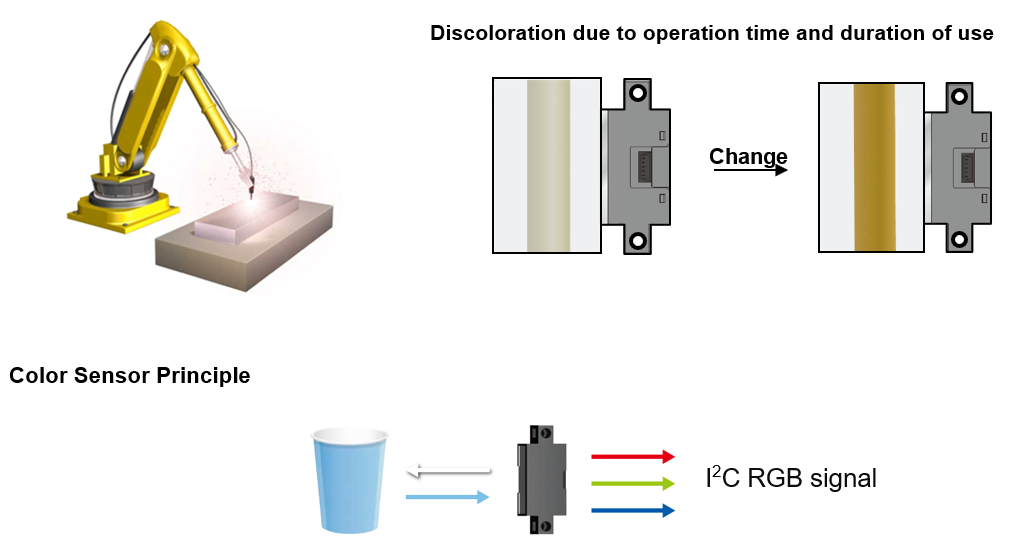

- Monitoring oil deterioration in hydraulic equipment

- By installing a color sensor next to the hydraulic tank of Daikin Industries, Ltd.’s “Eco-Rich R” hybrid hydraulic system, the oil deterioration status of each piece of equipment can be quantitatively monitored by color.

The hybrid hydraulic system “Eco-Rich R” is installed in each machine in a factory as a power source for industrial machinery, including machine tools. Color sensors are used to remotely monitor oil deterioration in the hydraulic tanks of each machine tool in real time, and unified management through the factory’s centralized control system enables the plant maintenance personnel to replace lubricant at the optimum timing for each machine.

- Exhibiting at trade shows

- Applications utilizing this sensor will be exhibited at the Daikin Industries, Ltd. booth at the 31st Japan International Machine Tool Fair “JIMTOF2022″ to be held at Tokyo Big Sight from November 8 to 13, 2022.”JIMTOF2022”:https://jimtof.org/en/index.html

Major applications

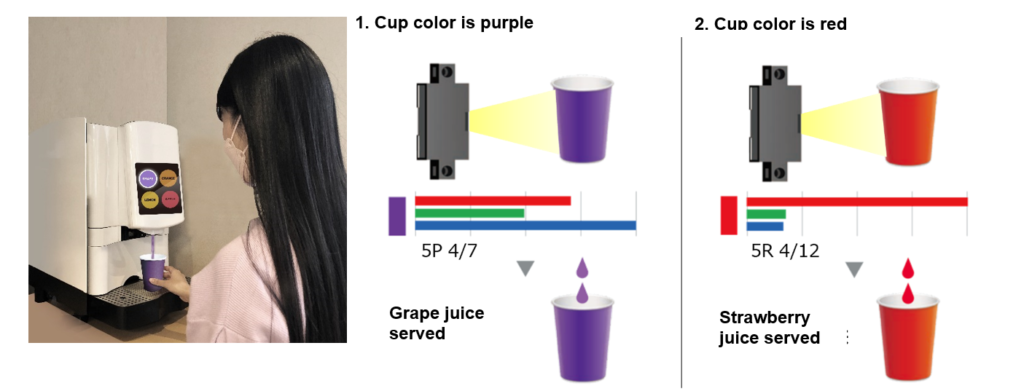

- Drink dispenser

Signal output according to the color detected by the color sensor allows configuration of equipment operation based on the color information of the object. The ability to identify the color of the cup and serve a set drink contributes to the multi-functionality of the equipment and automation of operations. It also reduces beverage disposal losses due to wrong button operation.

Image of application in a drink server

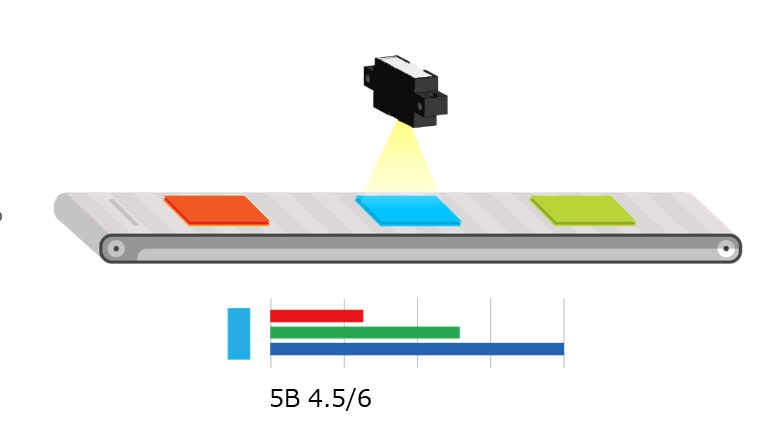

- Object detection on the production line

The presence or absence of an object to detect can be confirmed by using a signal output from a color sensor for each color of the detected object. Detecting objects by color contributes to stable operation of equipment.

- Monitoring of lubricant deterioration in arm robots, elevators, etc.

A color sensor monitors the oil color of the drive parts, allowing quantitative assessment of oil deterioration for each piece of equipment by color, contributing to more efficient equipment maintenance

A color sensor uses a white LED as its light source to emit light and receive reflected light (the ratio of red, green, and blue is unique to each color) determined by the color of the detected object. The color sensor separates the reflected light received into red, green, and blue, and outputs the red, green, and blue data (RGB data) as voltage values using the I2C communication method.

For example, in the case of red and yellow detected objects, the red, green, and blue output values from the color sensor are different for red and yellow reflected light by the white LED, allowing differentiation of red and yellow.

Product Specifications