Interview with Luca Corli, Sales Director Seica Worldwide

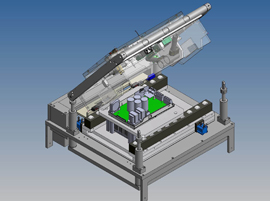

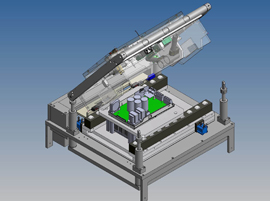

Q: Not so long ago your company introduced the Compact Multimedia Test System (MTS) as a practical and versatile functional test solution configured with all of the resources needed to test multimedia products, such as infotainment platforms in the automotive sector. What is Seica aiming for with this solution?

The goal of Seica’s Compact Multimedia Test System (MTS) is to offer a flexible and customizable solution, ready and able to meet the challenges posed by the latest technologies on the market.

Q: What stands behind the development of the MTS?

Based on 30 years of experience in test, we decided to define a platform dedicated to the functional testing of multimedia products.

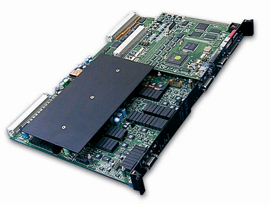

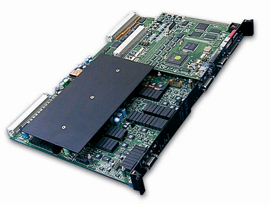

Starting from the most common communication buses (RS232, USB, Ethernet) including those specific to the automotive industry (CAN, LIN, Most, Flexray), through to video and audio validation, all the way up to the most complex RF combinational test, the Compact MTS is designed for the integration of all of the hardware and software resources necessary to satisfy any requirement.

Q: The Compact MTS is based on Seica’s VIP platform. What are the benefits of using this base?

Q: The Compact MTS is based on Seica’s VIP platform. What are the benefits of using this base?

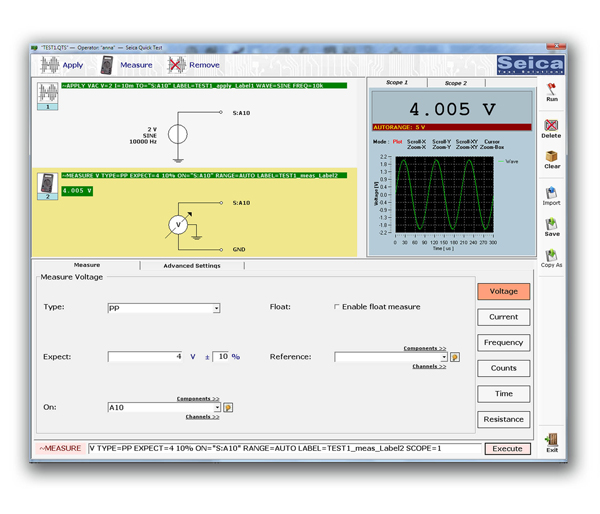

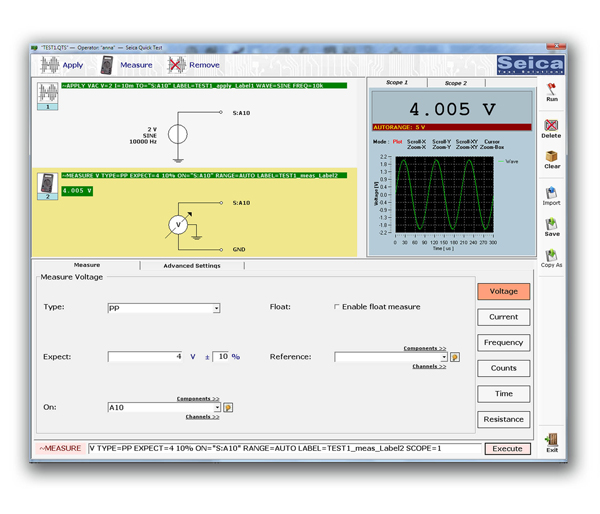

That’s right. Like all Seica systems, our VIP platform serves as the base of the Compact MTS. The VIP platform is a fully integrated combination of advanced technology and simplicity of use, enabling high performance in-circuit/functional test performance.

The sophisticated integrated measurement system (ACL module), based on DSP technology, is able to execute measurements and conditions, as well as manage signals in a fully automatic mode.

Q: Does the VIP platform allow parallel testing?

Of course. The platform includes full parallel test capability. This is an important feature of the Compact MTS. The solution implemented by Seica enables true parallel testing of up to four jobs, running completely simultaneously and independently.

Q: The list of the video technologies used in the latest consumer electronic devices is constantly increasing: Blu-ray Disc, HD DVD, 1080p, High-Definition Multimedia Interface (HDMI), Digital Visual Interface (DVI), S-Video, LVDS and CVBS standard, just to name a few. How does the Compact MTS address this long list of video technologies?

The Compact MTS integrates the latest solutions to accurately capture the analog signal with high-resolution digitizers, while capturing or generating digital video interfaces. The flexibility of the system allows manufacturers to keep up with new video standards while meeting aggressive time-to-market and price targets.

Q: What else besides video test is the solution able to perform?

Q: What else besides video test is the solution able to perform?

Closely related to video test, audio signal analysis can be performed on the Compact MTS using its software to manage both the integrated Seica instrumentation as well as any additional external instruments.

Q: What kind of analog signals can be measured?

Q: What kind of analog signals can be measured?

With our solution it is possible to generate and measure analog signals like THD levels, signal-to-noise ratio, etc. or to decode digital audio signals such as S/PDIF or I2S. Parallel acquisition of different audio channels can also be provided to increase test throughput.

Q: Considering the fact that, today, RF devices are integrated in a wide range of products, from wearables to high-definition mobile phones and automotive applications – how does Seica encounter the associated challenges?

Given this scenario Seica has designed its automated test system to easily allocate the required instrumentation and the proper handling solution for signal routing and management.

Q: What does Seica do the reach top performance with it’s solution?

Integration of the most advanced instruments is a must, but the design of the shielded fixture solution is also a key differentiator to reach the best performance, thus lowering the cost of testing. BT, Wifi, Cell phones, GPS, RFID, and ZigBee validation are now a basic capability of the Compact MTS.

Q: Is there anything you would like to highlight regarding the solution’s communications capabilities?

Q: Is there anything you would like to highlight regarding the solution’s communications capabilities?

Given the background that the communications speeds have increased and electronics have expanded into more and more safety-critical areas, there has been a shift in the technology. The flexible hardware and software architecture of the Compact MTS provide the most advanced integrated solutions: RS232 serial bus, automotive communications buses such as Lin, CAN (up to 500Kbps), LIN, Electrical and Optical MOST and FlexRay (operating at 10Mbps) reaching the high throughput standards over Ethernet.

Q: Information and the technology needed to collect and analyze data, is key to the successful digitalization of the manufacturing process, which is at the heart of the Industry 4.0 concept. Does the Compact line take all this into consideration?

Certainly. The Compact line has all of the capabilities needed for implementation in any Factory 4.0 scenario, providing the possibility to plug in any proprietary or third party information system to achieve the desired goals.

Q: Is there anything else you would like to emphasize regarding your company?

What in fact is important is our global support network. Thanks to the global extension of Seica and its subsidiaries, we can ensure local service support wherever the customer needs it, in addition to 24-hour telephone assistance.