CGS applies electrical contact on all six sides

World’s most compact single-head test station to be introduced on productronica stand A1.259

World’s most compact single-head test station to be introduced on productronica stand A1.259

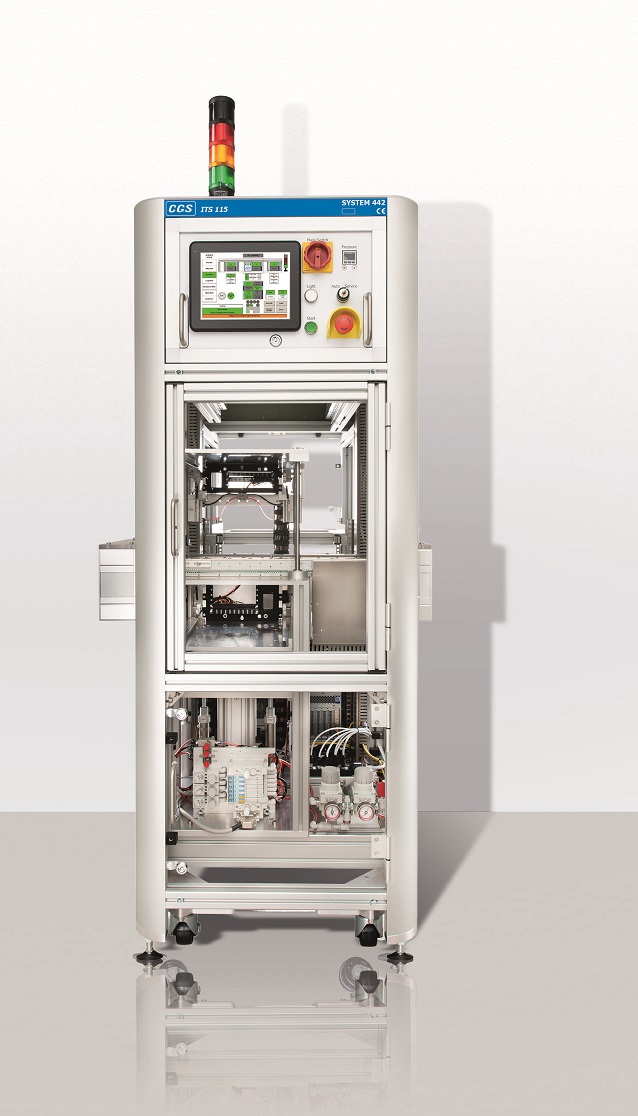

At productronica, CGS GmbH from Munich will present the world’s most compact single-head inspection system, the inline test station ITS 115. It processes the multiple PCB-format N5 (max 175 x 175 mm) and offers up to 1,000 contact needles, randomly placeable on upper and lower side. In addition, electrical contact can be applied to 90-degree plugs on four sides with pneumatically actuated test probes. All test points specific to the device under test are combined in a cassette module that can be changed by the operator within a minute. The system can be built in two lanes to halve the cycle time. A sophisticated design allows for easy access to all interfaces and signal interconnection points.

Like all inline-test systems from CGS, the ITS 115 is based on the patented double-stroke test head, which simultaneously contacts the device under test from above and from below. The clamping force of world’s most compact single-head testing machine allows for up to 1,000 contact needles, which can be randomly distributed on the upper and lower contact bed. In addition, electrical contact can be applied to an unlimited amount of 90-degree plugs on all four sides via pneumatically actuated test probes. Thus, the number of potential contact points to the test object is substantially increased and more than enough even for complex electronics.

All contact points are combined in a top and bottom cassette. The complete, test-object specific cassette module can be changed by the operator within a minute, that way minimizing downtime.

All electrical signals are provided either via VPC or Pylon interface. An integrated stroke counter is available as well, as is the possibility to integrate customer-specific additional hardware into the cassettes. It goes without saying that all parts in the area of the device under test are equipped with ESD-compatible surfaces.

Thanks to its slim design, the ITS 115 fits through virtually any office door. Large flaps provide direct access to all machine areas; in addition, the test station is vertically divisible, which facilitates upgrades of the testers as well as maintenance in the area of the test heads. Due to the modular and standardized construction of the machines, only a few spare parts are required in an emergency.

The user interface of the ITS is structured in a task-specific manner. All essential functions for a specific assignment are clearly arranged on one page and provide intuitive access. Access authorisation is governed by different user levels. Software updates can be installed via remote maintenance access.

An essential component of the ITS is the inline-module band IMB, equipped with ESD-compliant conveyor belts. The double-track belt can be individually adjusted to the width of the test object by means of servo-electrically displaceable guideways. In addition to a software-adjustable speed, the IMB has other settings such as soft start, decelerating or reverse direction. Stoppers, detection sensors and barcode scanners can be mounted at any position.

Several ITS stations can be connected in a row. Thus, different test and programming tasks can be performed one after the other. Depending on which processes are required, the individual ITS systems can be switched on or off. In this case, the devices under test simply pass through the shutdown systems.

CGS’s inline test station ITS 115 is the world’s most compact single-head inspection system. It will be presented at productronica 2019, booth A1.259.

With more than 30 years of experience in the fields of electronics, mechanics and software, CGS GmbH from Markt Schwaben, east of Munich, develops and manufactures test systems and test software for electronic assemblies. The product range is rounded off by a flexible, certified programming device for sensors, which is also optimized for use in production lines.

The customers of the family-owned enterprise mainly come from the automotive, aerospace, home appliances and energy sectors. They all appreciate the turnkey solutions of CGS from a single-stop source: from planning and development to production and maintenance, they are looked after directly by the manufacturer and have a dedicated contact person.

The system development of CGS creates standards in the design of test systems for electronics, but also develops station-time optimized, customer-specific and individual solutions. With its state-of-the-art machinery, the company manufactures high-precision mechanisms and adapters for applying optimum electric contact to virtually any test item.

On customer request, CGS provides test programs under LabWindows / CVI, TestStand, LabVIEW or other software platforms.