Technology changes at a rapid pace and businesses that do not change with it often stay far behind in the race as others take a leap.

Technology changes at a rapid pace and businesses that do not change with it often stay far behind in the race as others take a leap.

In these times, the fastest growing technology is automation that is helping industries around the globe to to increase production and decrease time consumption.

The fast paced action and demands have forced companies and industries to shift their setup from mechanization to automation.

A mechanized system involves human intervention at every process. It is not only time consuming, but can also be costly, especially due to the risk of human errors.

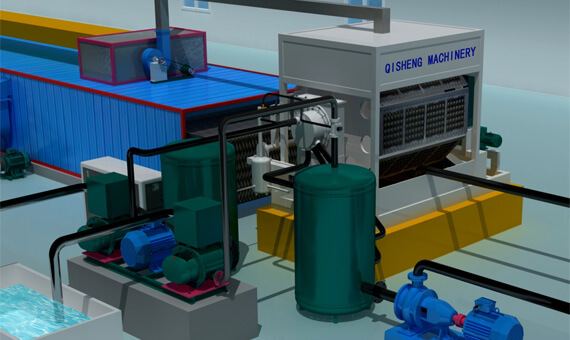

On the other hand, we have automated systems which incorporate the use of automated devices, softwares, machines and even robots to carry out tasks. Many companies like PulpBiz are making machines to help business automate processes and get more out of the opportunities that they get.

While automation might have naysayers, it surely helps the business. Let’s have a look at five benefits of industrial automation:

1. Boosts Productivity

Every business wishes to enhance its level of productivity because more productivity equals to more profits. This can be done by introducing automation as machines can do more work than humans and at a faster rate. As a result, you get more in less time.

Consider the textile industry. Hand embroidery might be beautiful, but it takes days to complete a shirt. Hands get tired and one needs to take breaks as well. Plus, there is also the risk of the design going haywire. However, there are no such issues when you use a machine to do the job.

You can feed a design on a machine and it will do the job quickly. This way, you can get more shirts embroidered in less time and without any faulty pieces.

This is just a small example of how automation can help, but such examples can be found in almost all industries.

2. Saves Money

Human interference is minimized when an industry switches to automated system. The processes are repeated with accuracy and at a much faster rate than they were on manual system. This reduces the number of cycles for production, which helps save money as it also reduces the need to hire people to do the job.

However, you might need a good amount to invest in your business to try automation as machines can be expensive.

3. Improves Product Quality

In manual work, mistakes are bound to happen which can cost you a heavy loss. A miscalculation can destroy an entire production and cost you millions. Working with an automated system instead has many benefits including a boost in the production quality.

his is because the room for error is minimized to almost none and products are manufactured with 100% accuracy. This speeds up the production process and keeps the quality consistent as well.

An automated system makes it possible to monitor, manage and control entire production cycle from beginning to end. This ensures that quality is not compromised.

4. Eliminates The Need To Do Manual Routine Inspections

Just like automated machines can keep on producing goods on their own, they can perform manual checks as well.

All you need to do is define parameters by adjusting the process variables. These variables are checked automatically with every cycle to see if they match.

The entire cycle is a loop which keeps on repeating. In case an anomaly is discovered, the entire process is halted until the problem is solved.

This way, errors are kept at bay and high quality of products is maintained.

It is obvious that automation provides benefits to all businesses. If you have not already introduced automation to your business then you should consider doing so as the benefits of it cannot be neglected.

It does not matter how big or small your business is, you can automate several processes to see a jump in your profits.