Advances in battery technology are challenging automakers and their suppliers to meet higher market demand for hybrid and electric vehicles without compromising quality.

2017 marks the 20th anniversary of the Toyota Prius, the world’s first widely-available hybrid electric vehicle (HEV). Since then more than 12 million HEVs have been sold around the world. Yet sales of HEVs and their full-electric counterparts still account for only a relatively small proportion of the global car market. Thanks to recent advances in battery technology, however, this is all about to change.

2017 marks the 20th anniversary of the Toyota Prius, the world’s first widely-available hybrid electric vehicle (HEV). Since then more than 12 million HEVs have been sold around the world. Yet sales of HEVs and their full-electric counterparts still account for only a relatively small proportion of the global car market. Thanks to recent advances in battery technology, however, this is all about to change.

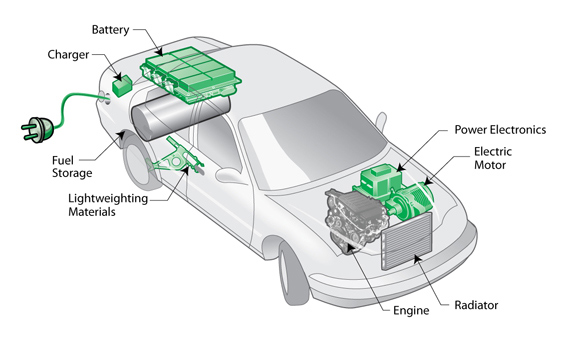

“Aside from charging infrastructures, battery cost and life have proved the greatest obstacles to growth in the HEV/EV market so far. It’s definitely not the electric motor or power electronics that are holding back the pace of the industry,” says Professor David Greenwood, head of advanced propulsion systems at WMG, The University of Warwick.

Battery costs for HEVs and EVs can be as much as two to three times greater than the motor and power electronics combined. However, they have decreased significantly over the last eight years; meanwhile energy density has almost doubled. These advances can be attributed to improved electrochemistry and packaging of the electrochemistry, as well as economies of scale.

“It’s the speed at which we can improve the battery that will ultimately impact sales and usage of HEVs and EVs,” Professor Greenwood continues. “Right now battery performance is increasing on a fast trajectory but to get to a point where HEVs and EVs are fully democratised and make up 60-70% of all sales, we need to double the energy density again.”

Current research into making this leap is investigating the use of silicone and lithium anodes and different ways of structuring electrodes. Further research on sodium-ion chemistries could yield significant cost benefits, as well as different ways of packaging the cells into modules.

Made for mass production

As the market continues to take off in line with battery technology, automakers will need to adapt motor designs to suit higher volume production. One way is by selecting windings that permit a high degree of manufacturing automation. OEMs will also need to analyse manufacturing processes to ensure high quality.

“There are plenty of manufacturers out there that are able to produce electric motors in high volumes but the challenge is meeting automotive levels of quality,” Professor Greenwood comments.

Certain ways of cutting laminated steels, for example, are known to negatively affect their magnetic properties, which reduces the efficiency of the electric machine.

“It’s not just about designing a good machine but designing one that when mass-produced still delivers on its original promise,” he adds.

New opportunities for the coil winding community

The growth of the HEV and EV market is good news not only for the automotive industry but all involved in the business of coil winding.

“HEV and EVs are now starting to account for four to five percent of all vehicle sales in some months, which means we are no longer just selling to early adopters but to real customers. This is the point at which volumes can really change, opening up supply chain opportunities for a whole range of organisations, who perhaps weren’t selling to the automotive industry before but now could – if they can design their products and services to meet the cost, volume and quality requirements of that market,” Professor Greenwood explains.

Professor Greenwood will be approaching this audience at CWIEME Berlin (Coil Winding, Insulation & Electrical Manufacturing Exhibition) in a seminar entitled ‘Roadmapping the EV future: Battery technology, mass manufacturing and the prospects ahead for energy storage’ on Tuesday 21st June 12:20-13:00. He will also be taking part in a CWIEME panel discussion on electric vehicle technology alongside automotive OEMs and their suppliers on Thursday 22nd June 09:30-10:30.

“Many of the speakers in the conference programme will be focussing on the specifics of electric motor design. My session aims to provide a context to these topics – what the market is going to look like and the factors driving it,” he concludes.

Academia meets industry

Professor David Greenwood leads the advanced population systems team at WMG with a focus on energy storage (battery systems), energy conversion (electric machines and power electronics) and energy management. He also provides academic leadership for the development of R&D activities within the UK’s National Automotive Innovation Centre, serves as a board member for the Low Carbon Vehicle Partnership (LowCVP) and the Avanced Propulsion Centre (APC), and is a member of the Automotive Council Technology Group and the Energy Scienfic Advisory Committee.

Prior to joining the University of Warwick, Professor Greenwood was head of hybrid and electric systems for Ricardo UK Ltd., preparing automotive industry technology roadmaps and research priorities for the New Automotive Innovation and Growth Team (NAIGT), Technology Strategy Board (TSB) and Automotive Council.