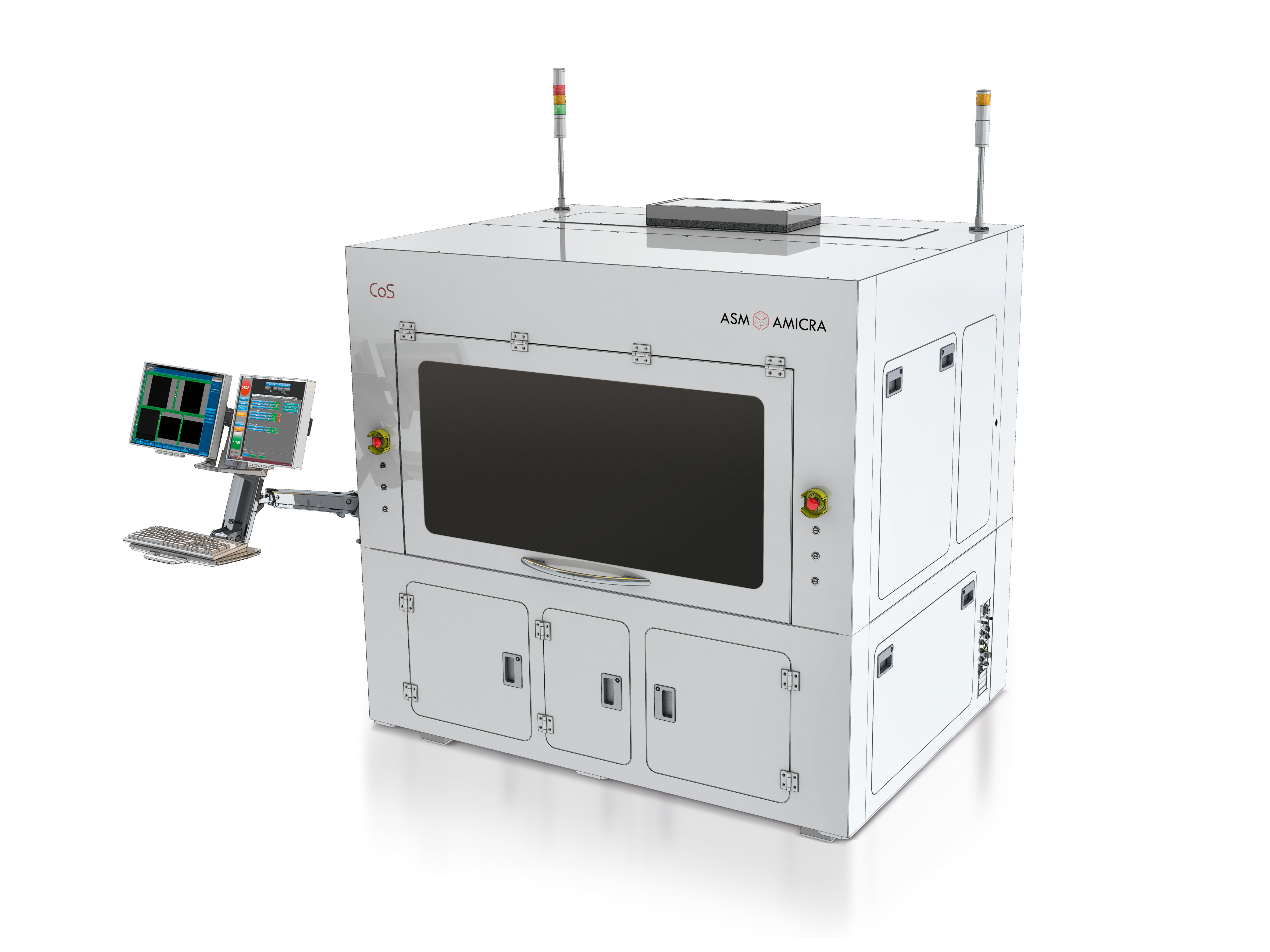

Munich (Germany), December 12, 2019 – With advanced packaging technologies, dies and SMT components can be combined into extremely compact and function-rich submodules, which creates the prerequisites for new electronic applications in a wide variety of industries. Technology leader ASM offers a broad selection of innovative advanced packaging solutions that can be lined up to complete process chains from wafer pick-up to die fan-out to bonding, molding and packaging. ASM’s innovations include the ASM SilverSAM as a powerful sintering solution, the latest generation of the SIPLACE CA for fan-out wafer-level packages, and the SIPLACE TX micron for high-volume system-in-package applications. And the ASM AMICRA CoS, winner of the productronica innovation award, uses a rotating bonding station to perform the high-precision alignment of optical dies with significantly faster cycle times.

“As the largest equipment supplier to the electronics industry, we combine in our advanced packaging solutions the process expertise and technologies from our Backend Equipment and SMT Solutions divisions. We also acquired specialists like AMICRA and NEXX in recent years. Their new products are already putting technologies and R&D synergies to successful use within the ASM Group. This makes us the only equipment maker that can offer completely even complex process chains with our extensive portfolio of advanced packaging solutions. This allows users to further miniaturize their electronics while improving their performance and durability at lower costs,” says Hubert Herzberg, Head of Back End Systems Europe with ASM PT about the growing importance of advanced packaging for ASM and the electronics industry in general.

“As the largest equipment supplier to the electronics industry, we combine in our advanced packaging solutions the process expertise and technologies from our Backend Equipment and SMT Solutions divisions. We also acquired specialists like AMICRA and NEXX in recent years. Their new products are already putting technologies and R&D synergies to successful use within the ASM Group. This makes us the only equipment maker that can offer completely even complex process chains with our extensive portfolio of advanced packaging solutions. This allows users to further miniaturize their electronics while improving their performance and durability at lower costs,” says Hubert Herzberg, Head of Back End Systems Europe with ASM PT about the growing importance of advanced packaging for ASM and the electronics industry in general.

Silver sintering: Stable connections for power electronics

High temperatures near the melting point of classic soldered connections and an environment that is hostile to electronics require new materials and processes in electric vehicle drive trains. With its SilverSAM, ASM is introducing a highly productive and flexible sintering press for silver-containing soldering pastes in applications such as power modules. In addition, the company óffers solutions for wafer dicing (ASM Laser 1205), metal-coating of dies (NEXX Apollo), paste printing (DEK Galaxy), and molding (AMS Idealmold 3G).

Precise alignment during sensor production

Precise alignment during sensor production

Modern assistance systems employ various optical sensors. With the ASM Autopia and ASM AMICRA CoS, ASM has two solutions for the high-precision dynamic alignment of lenses and optical dies in camera, lidar and radar applications. The ASM AMICRA CoS impresses not only with its accuracy of 3 µm @ 3 sigma, but with a cycle time of only six seconds thanks to its rotating bonding station, innovative multi-pick head and two bonding stations. Users can choose between laser and ceramic heaters during eutectic die-bonding. And for high-volume production requirements and the combined placement of bare dies from the wafer and SMT components from tapes onto large substrates, ASM presents the latest generation of its extremely flexible and powerful SIPLACE CA (Chip Assembly).

SiPs for Car2X communication

SiPs (SIP = system in package) make it possible to combine the functional diversity of modern communication modules with the automobile industry’s quality requirements. With solutions like the ASM ORCAS (molding), ASM NUCLEUS (flip-chip placement) and ASM SUNBIRD (taping of bare dies), ASM is able to present a complete process chain, whose final link is a SIPLACE TX micron for the high-volume placement of SiPs. It takes bare dies and SMT components from tapes and places them with SMT-typical speed and precision.