Authors

Monitoring food consumption has numerous benefits not only in the prevention of food wastages but also in studying various food and dietary habits of people. In a country like India having a population of 1.25 billion where majority of the diet consists of pulses and rice there is no perfect way to determine how much of the food is being consumed daily/weekly or annually, other than manually keeping the track of this information in household. In Every household there are at least 10-15 such containers (made of plastic or steel) containing various pulses and food items .Using STMicroelectronics components (MCU ,Sensors and NFC-Near Field Communication) such plain containers can be converted to smart containers which can help in tracking the amount of food consumed.

The purpose of this article is to explain the design and operation of such prototype developed by STMicroelectronics.

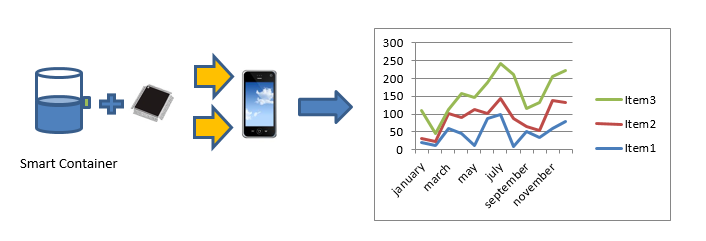

A system consist of Microcontroller(MCU), Sensors and connectivity module (NFC/Bluetooth) can be used for food content level detection in a container and this information can be transferred to a remote PC or Handheld device manually (or automatically).Food content can be solid(pulses,rice,sugar,etc) or any liquid(juice, oil ,milk ,etc).

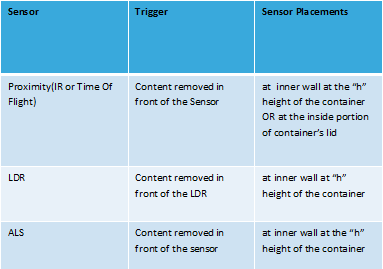

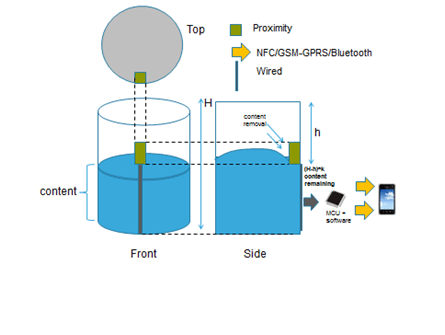

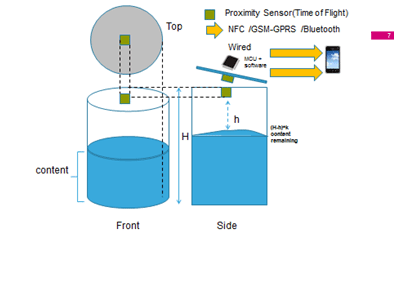

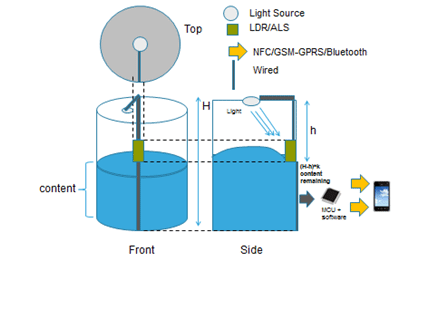

LDR(Light Dependent Resistor), Proximity and/or Ambient Light Sensor can detect the level of food in a container via a trigger depending on the type of the sensor and intimate MCU(Micro Controller Unit) which then transmit this information to a remote PC/Mobile via NFC(Near Field Communication) or Bluetooth. Transmitted information could be the amount and the type of the food whose information is already stroed in the MCU flash .e.g container #1 containing pulses1,container #2 containing pulses #2 and so on .See the trigger table below for the respective sensors and their placement with respect to the container below .MCU can also store each box’s content’s information(density,height,type) and can calculate the amount of the content present based on the height “h” or “H-h” of the content.

Trigger/Sensor Placement:

The advantages and Marketing relevance of such a system are:

- This method can be used in Smart homes/Kitchens for automatic tracking of the food consumption

- Food Items supply chain – Malls, Supermarkets, restaurants, grocery shops to track the amount of food sold.

- In chemical industries to keep the tracking of the amount of chemicals (liquids especially) consumed.

- Data can be used by the Government authorities to regulate and monitor the food stock.

System Configuration:

The given system can be designed in various ways. The main idea is to track the food and store the information in MCU from which the information can be retrieved manually by a NFC enabled Phone or can be transmitted automatically to the PC or hand-held device periodically (via Bluetooth)

Below are the main types of system configurations:

Type A:

Type B:

Type C:

Modes of Operation:

Auto Mode: The MCU will periodically scan the content at the time of the lowest activity (at Midnight) every configurable time (day, week, etc) and send the information via Bluetooth or GPRS to a remote PC or mobile device.

Manual Mode: The MCU will scan the content at the time of lowest activity (at Midnight) every configurable time (day, week, etc) and store it in the NFC tag and when a NFC enabled Phone running application is brought in the vicinity of the NFC tag ,it will retrieve the information from it and display in appliction GUI.

The application can send this information to the remote the server which can be viewed on web from the PC as well. This web and the mobile application can give rise to ecosystem which has numerous use cases which are out of the scope of this article and left to reader for brainstorming.One such example is giving rise to application for developers to track carbohydrate, fibre and Protein consumption by a family per week which can be linked to their social account.

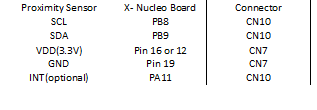

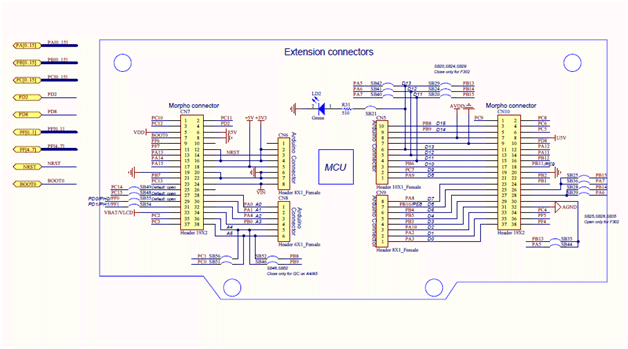

Internals of Working Prototype using STM32 X-Nucleo board, Proximity Sensor and X-Nucleo-NFC01A1 board:

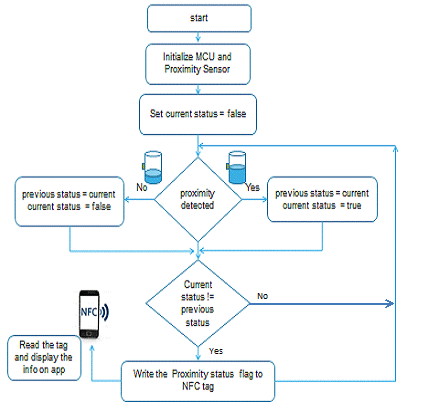

Connect the Proximity sensor with the X-Nucleo board and then stack the X-Nucleo NFC board on Top of it. Below is the flow diagram for the basic impementation.

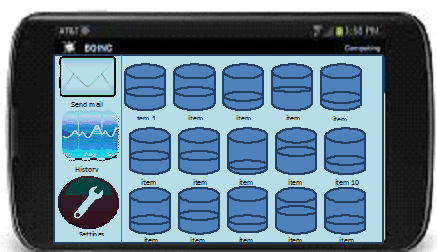

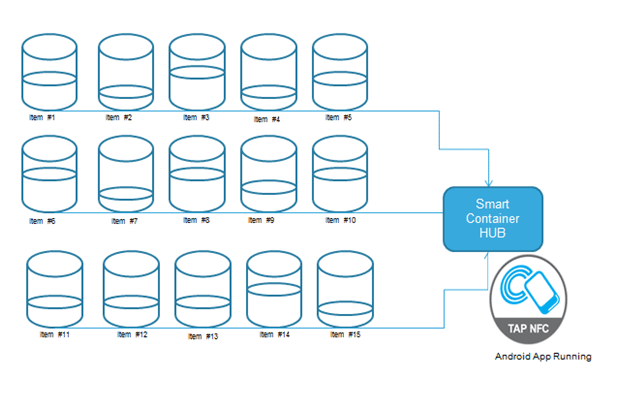

Similiarly a network of smart containers can be setup , all connected to a common hub having NFC Tag containing the information for each of the containers and their current content level and this can be displayed using the android app as below.

Proximity status information can be readback from the NFC tag using android app for each container and the content status can be displayed as below showing the status of content in various containers.

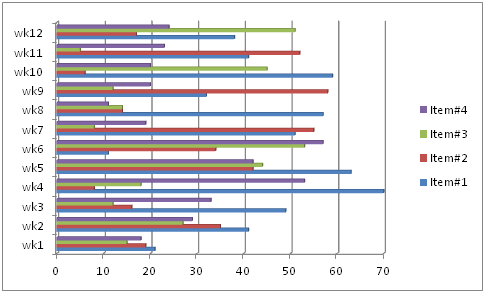

The information received in the phone can be uploaded to web by the application and demonstrated in Graphical form as below.

Conclusion

Smart containers are the efficient way to track the food content being consumed in every household. Due to advent of mobile phones and tablets which are available in every household, they can be easily coupled with the smart containers to track the food content and hence regulate the food budgeting and dietary habits.It doesn’t cost much per household containers and has easily replaceable parts thus reducing the maintenance cost.

References:

X-Nucleo Board: http://www.st.com/web/en/catalog/tools/FM116/SC1971?sc=x-nucleo

X-Nucleo- NFC: http://www.st.com/web/catalog/tools/FM116/SC1444/PF260759?s_searchtype=partnumber

Proximity Sensor:http://www.intersil.com/content/dam/Intersil/documents/isl2/isl29023.pdf