Electronics manufacturers show great interest in solutions for the integrated smart factory

Successful Nepcon Asia 2020

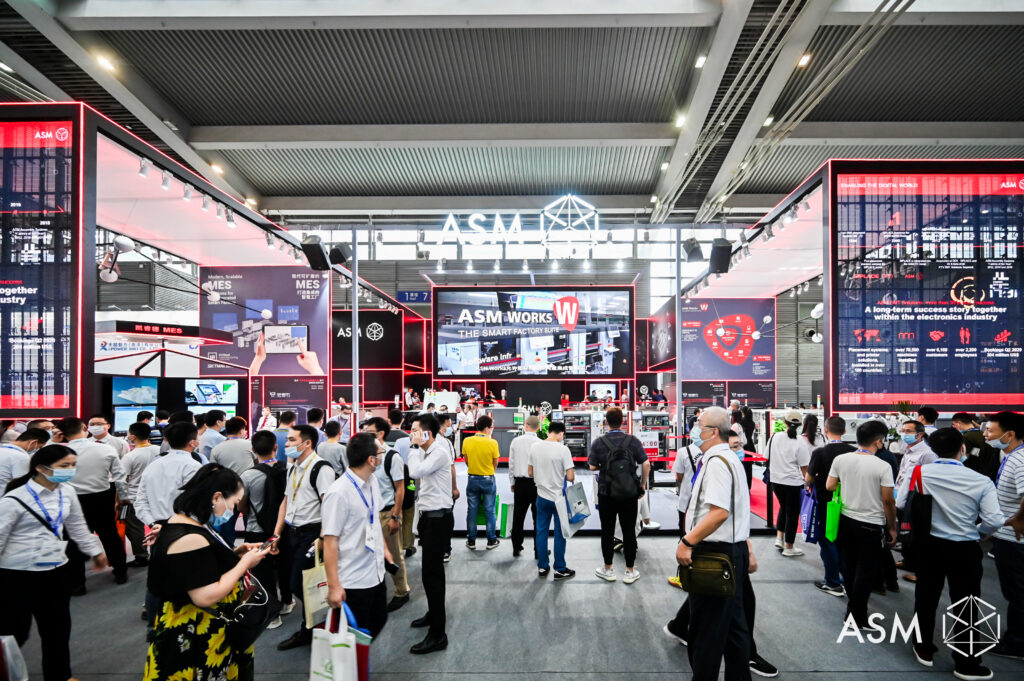

Singapore, September 14, 2020 – The 2020 Nepcon Asia trade fair in Shenzhen, China was again a big success for technology leader ASM. The live shows in the Integrated Smart Factory Arena with AIV-supported automatic material logistic and changeovers, which have been developed together with Hikrobot, attracted large numbers of visitors. The demonstrations on the SMT lines were supplemented with modern presentation techniques such as AR. Other highlights on the booth included the DEK TQ stencil printer, the world’s first self-learning inline expert system for autonomous process optimization ASM ProcessExpert as well as the modular software package ASM Works, the software infrastructure for the integrated smart SMT factory. The booth also showcased the newest SIPLACE SpeedStar placement head providing a breath-taking 23% speed increase of our placement solutions SIPLACE SX, SIPLACE TX and SIPLACE TX micron. Meanwhile, DEK TQ and ASM ProcessExpert won the Vision Award from SMT China during the exhibition. DEK TQ won the Vision Excellence Award, the highest type of Vision Award, because of its outstanding performance in speed, floor space, performance and wet printing accuracy, with the highest score among all the shortlisted products.

Singapore, September 14, 2020 – The 2020 Nepcon Asia trade fair in Shenzhen, China was again a big success for technology leader ASM. The live shows in the Integrated Smart Factory Arena with AIV-supported automatic material logistic and changeovers, which have been developed together with Hikrobot, attracted large numbers of visitors. The demonstrations on the SMT lines were supplemented with modern presentation techniques such as AR. Other highlights on the booth included the DEK TQ stencil printer, the world’s first self-learning inline expert system for autonomous process optimization ASM ProcessExpert as well as the modular software package ASM Works, the software infrastructure for the integrated smart SMT factory. The booth also showcased the newest SIPLACE SpeedStar placement head providing a breath-taking 23% speed increase of our placement solutions SIPLACE SX, SIPLACE TX and SIPLACE TX micron. Meanwhile, DEK TQ and ASM ProcessExpert won the Vision Award from SMT China during the exhibition. DEK TQ won the Vision Excellence Award, the highest type of Vision Award, because of its outstanding performance in speed, floor space, performance and wet printing accuracy, with the highest score among all the shortlisted products.

“I am very glad to see the innovation of ASM at the exhibition. The new solution of smart factory is refreshing. My personal favorite is the automatic material logistics solution supported by AIV.” In the new normal during and after the pandemic, ASM can consistently provide strong technical and service support for electronics manufacturers, which provides a strong guarantee for them to resume production, continue to develop, and further enter the smart factory. ASM, with its leading technology and process quality in the placement machine and printing machine industry, helped OPPO to develop the advanced concept of smart factory as early as the end of 2017. “At present, the first stage of integration and testing has been successfully completed.

“I am very glad to see the innovation of ASM at the exhibition. The new solution of smart factory is refreshing. My personal favorite is the automatic material logistics solution supported by AIV.” In the new normal during and after the pandemic, ASM can consistently provide strong technical and service support for electronics manufacturers, which provides a strong guarantee for them to resume production, continue to develop, and further enter the smart factory. ASM, with its leading technology and process quality in the placement machine and printing machine industry, helped OPPO to develop the advanced concept of smart factory as early as the end of 2017. “At present, the first stage of integration and testing has been successfully completed.

With the continuous implementation and introduction of ASM integrated smart factory scheme in xx, the two sides will also carry out more extensive and in-depth cooperation in production automation, process optimization and other aspects” says Mr. He Aiting, Senior Manager, Guangdong OPPO Mobile Telecommunications Co., Ltd.

Live: Automated material logistics and setup changeovers

Live: Automated material logistics and setup changeovers

The Integrated Smart Factory area showed a successful integration example. ASM and Hikrobot jointly demonstrated the AIV automatic material logistics and line changeover solutions. Through the AIV, it can accurately connect with SMT placement equipment to realize the automatic material setup from the material preparation area to the production line, which was controlled with software from the portfolio of ASM Factory Solutions. No manual intervention is needed in the whole process. The new ASM AutoRefill Feeder, whose ability to automatically insert two component tape reels simplifies refills and reduces their frequency, plays a special role in these demonstrations. At present, the automatic material logistics showed in the booth has been successfully tried out in the ASM SMT CoCs in China, and interested parties are welcome to make an appointment.

“The introduction of AIV into production has the advantages of flexible deployment, rapid expansion, high positioning accuracy, safety and reliability. This is also one of the processes with which ASM helps electronic manufacturers to realize their smart factory. At the same time, even existing customers can benefit from improved quality, capacity and flexibility due to the continuous upgrading and transformation of ASM solutions. This makes ASM a strong partner for customers looking to transform their productions into integrated smart factories. ” says Herbert Hofmann, Vice President and Managing Director of ASM`s Greater China SMT Solutions Segment.