Corporations and universities leverage engineering simulation software to solve challenging problems in the automotive, health care and industrial equipment industries

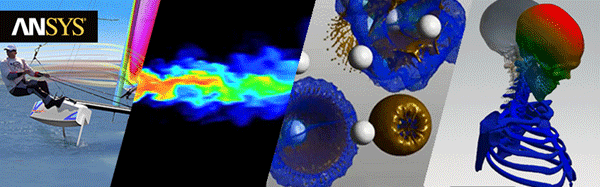

Bangalore, Jan 7, 2016 – From reducing aircraft emissions to pinpointing the degree of cervical degenerative disc disease before and after treatment, the six winning entries of the annual ANSYS Hall of Fame competition highlights how simulation software is solving the most complex engineering challenges across industries.

Bangalore, Jan 7, 2016 – From reducing aircraft emissions to pinpointing the degree of cervical degenerative disc disease before and after treatment, the six winning entries of the annual ANSYS Hall of Fame competition highlights how simulation software is solving the most complex engineering challenges across industries.

The contest gives ANSYS users the opportunity to showcase their simulation and engineering skills by producing striking images and animations. The submissions were divided into two categories – corporate and academic – and allowed ANSYS to select multiple “best-in-class” winners from each category.

The corporate winners are:

- Combustion Research and Flow Technology, Inc. (CRAFT Tech), specializes in high-fidelity computational fluid dynamics (CFD) simulations of complex flow and combustion problems. Using ANSYS, CRAFT Tech engineers accurately captured flame temperature suppression in aircraft propulsion and power generation systems, enabling aircraft engine manufacturers to reduce emissions and avoid potentially dangerous flameout conditions.

- Design Methods provides multidisciplinary consulting and designing services using state-of-the-art aerospace technologies. Design Methods used ANSYS solutions to successfully design an A-Class catamaran sail, enabling the company to offer a premium design service to sail manufacturers, sailing teams and private ship owners to improve the performance of any sailing ship.

- Lucy Electric, a leader in secondary power distribution solutions, specializing in high-performance medium voltage switchgear. Lucy Electric engineers used ANSYS electromagnetic field simulations to modelhow the effects in time-varying loads influence the current distribution among contact points in circular contact elements of electric switchgear. As a result, they reduced the number of failed tests and sped up the electric switchgear design process.

The academic winners are:

- City University London and Centre for Research and Technology Hellas, whose researchers used ANSYS solutions to model gas/oil droplets in a fluid catalytic cracking reactor for more efficient conversion in petroleum refining.

- Leibniz University Hannover researchers used ANSYS multiphysics solutions to design a novel two-frequency induction furnace used for melting metals. This enabled the researchers to create a design that prevents metal leakage, a known limiting factor for melts over a certain size.

- National Taiwan University of Science and Technology researchers used ANSYS solutions to model the human upper body to explore different surgical techniques and physiological movements, which led to successfully identifying the extent of cervical degenerative disc disease before and after treatment.

“It’s exciting to see the caliber of entries we receive each year for the Hall of Fame competition that highlight the value of engineering simulation,” said Mark Hindsbo, vice president of marketing, ANSYS. “Companies in virtually every industry are using simulation to accelerate the design process, reduce time to market and most importantly, innovate both in product performance and energy efficiency. These best-in-class winners provide valuable insight and highlight how simulation can be used to design the products of tomorrow.”

View the ANSYS Hall of Fame Archive at http://www.ansys.com/HOF for submissions from previous years’ competitions.